AlV

Crabs in a barrel

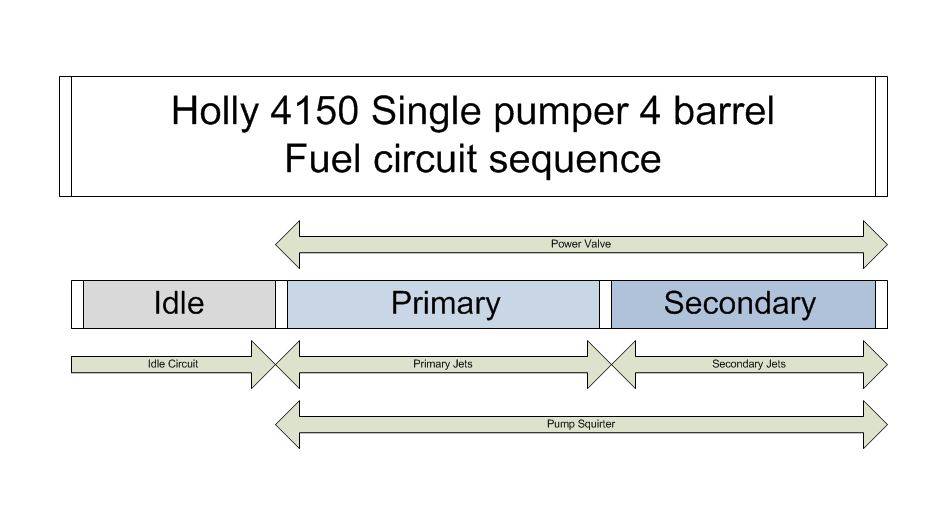

Hi FABO, I've been tweaking the carb on my Dart and want to better understand the sequencing of how and when fuel is delivered through the range. I drafted a simple and crude Diagram that depicts in general what I think is happening. Am I off? Does anyone have a better diagram?