Holley spreadbore 650 on a stock 318 and has the stock #56 jets in carb and 9.5 PV, it idles best when the mixture screws are all the way in. Could it have too small of jets in the carb? Should I bump them up a few jet sizes?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Holley idle mixture screws

- Thread starter gliderider06

- Start date

-

Frank Mopar

Well-Known Member

You might have the throttle plates open to far which is disabling the idle circuit. Idle screws all the way in should kill the engine.

That's a likely possibility and good way to describe it.

The longer explanation is the idle circuit feeds both the transfer slot and then the idle mix screws which control fuel to the idle port.

These carbs are designed to draw fuel from both the transfer slot and the idle port at slow idle.

When the throttle opens, already having fuel flowing from the transfer slot reduces the delay in increasing fuel to match the additional air.

If they are too far open at idle, then transfer slot happily supplies all the fuel the engine needs to idle.

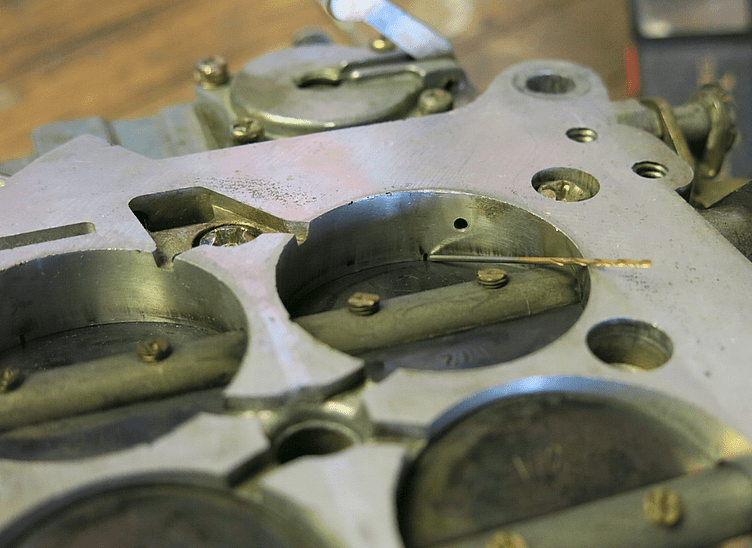

So the first thing to check is the transfer slots visible under the throttle at idle are in the range of .020 - .040"

You can check with feeler gage or drill bits.

While you're at it, write down how many 1/4 turns in of the idle speed screw from just touching gets .020, 030, and .040. Then you'll always know how far open the throttles are.

The longer explanation is the idle circuit feeds both the transfer slot and then the idle mix screws which control fuel to the idle port.

These carbs are designed to draw fuel from both the transfer slot and the idle port at slow idle.

When the throttle opens, already having fuel flowing from the transfer slot reduces the delay in increasing fuel to match the additional air.

If they are too far open at idle, then transfer slot happily supplies all the fuel the engine needs to idle.

So the first thing to check is the transfer slots visible under the throttle at idle are in the range of .020 - .040"

You can check with feeler gage or drill bits.

While you're at it, write down how many 1/4 turns in of the idle speed screw from just touching gets .020, 030, and .040. Then you'll always know how far open the throttles are.

Demonic

Well-Known Member

Also, on some Holley's it will idle/leak fuel into the carb if the Power Valve fails, usually by a carb backfire.

rklein383

Well-Known Member

- Joined

- Dec 2, 2005

- Messages

- 2,212

- Reaction score

- 1,805

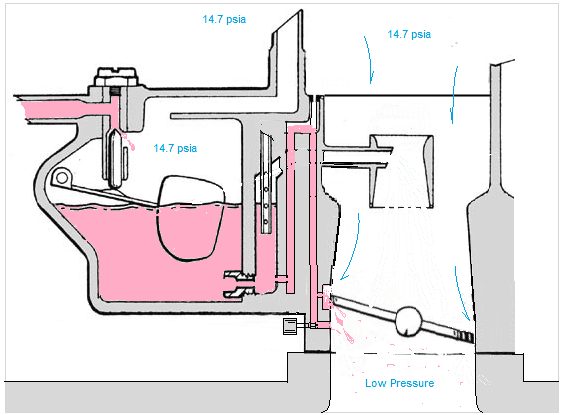

Good picture, as the pic shows, the jets only limit (unless severely undersized) fuel flow at wide open throttle. As air flows thru the venturi of the carb (narrowing of the opening), it creates a low pressure which allows the higher atmospheric pressure in the float bowl to squirt fuel into the air stream and down into the manifold. It seems most people want to change jetting for a rich condition at part throttle. Holley's use a power valve to alter part throttle fuel conditions in conjunction with the accelerator pump squirter.

Thanks again. After disconnecting the EGR, idle speed screw was backed off about 3 turns and she settled down nicely. Idle mixture screws are about 1/4ish turns from seated. It runs really smooth now.

I wonder if the PV was blown. It did backfire a few times at first startup. Maybe I'll pull the bowl off and check it tomorrow.

I wonder if the PV was blown. It did backfire a few times at first startup. Maybe I'll pull the bowl off and check it tomorrow.

furyus2

Well-Known Member

If the power valve is bad, you'll know it. I had one go bad, and the engine spit, and sputtered, and wouldn't idle., so I would think that yours is ok.

If the diaphram ruptures the bowl will empty through the vacuum passage into the manifold. Look down the carb ypou'll see a fuel - depending the gasket you might even see it around the base externally. If its idling decent doubt its ruptured.Thanks again. After disconnecting the EGR, idle speed screw was backed off about 3 turns and she settled down nicely. Idle mixture screws are about 1/4ish turns from seated. It runs really smooth now.

I wonder if the PV was blown. It did backfire a few times at first startup. Maybe I'll pull the bowl off and check it tomorrow.

Yeah, it idles super smooth. I don't think it's bad then.If the diaphram ruptures the bowl will empty through the vacuum passage into the manifold. Look down the carb ypou'll see a fuel - depending the gasket you might even see it around the base externally. If its idling decent doubt its ruptured.

Thanks,Paul

Also if the power valve is blown, it will run so rich your eyes will burn standing behind it.

-