67Dart273

Well-Known Member

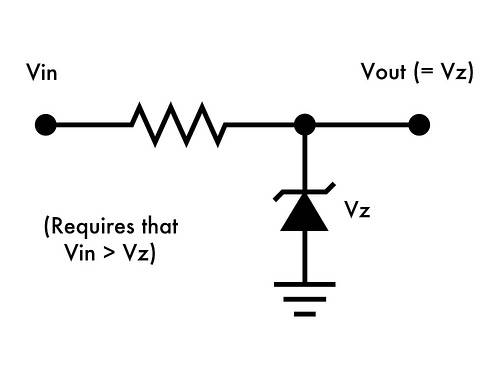

This is a basic zener regulator circuit

This is wired for positive supply applied to top left. If you know anything about basic diodes, THIS WOULD BE BACKWARDS

Current flows from NEG at bottom up through the zener, and back to POS at top left. The zener will be conducting "in reverse" or "avalanche." If the resistor was not there to limit current, the diode would destroy itself, zener or "standard"

The zener has a voltage rating, and as the current flows up through the diode, it reaches a "trigger" point (the diode rating) where it turns on. So at the top of the diode, would be nominally 60V if that is a 60V diode

The FUNNY thing about zeners to "us old guys" is that we? I? grew up with gas-tube regulators, which work NEARLY EXACTLY THE SAME WAY LOL

This is wired for positive supply applied to top left. If you know anything about basic diodes, THIS WOULD BE BACKWARDS

Current flows from NEG at bottom up through the zener, and back to POS at top left. The zener will be conducting "in reverse" or "avalanche." If the resistor was not there to limit current, the diode would destroy itself, zener or "standard"

The zener has a voltage rating, and as the current flows up through the diode, it reaches a "trigger" point (the diode rating) where it turns on. So at the top of the diode, would be nominally 60V if that is a 60V diode

The FUNNY thing about zeners to "us old guys" is that we? I? grew up with gas-tube regulators, which work NEARLY EXACTLY THE SAME WAY LOL