SS Lancer

Well-Known Member

Thanks ( LOCOMOTION )

371 - Cubic Inch "A" engine with 100 % Chrysler parts !!

Very interesting article and some good info coming from the Man ( Tom Hoover ) who managed the Drag Racing programs for Chrysler.

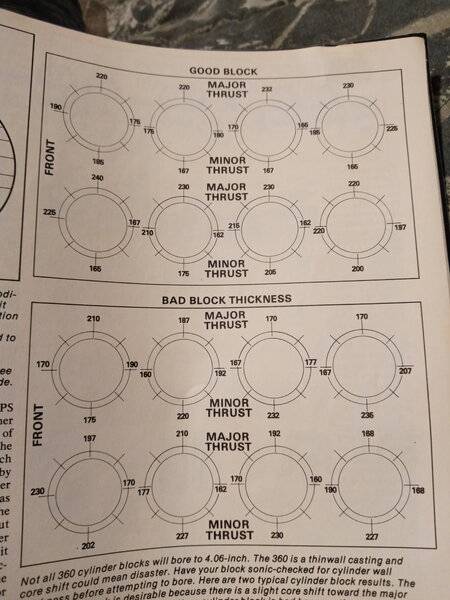

The heart of the 371- incher ( a 360 bored .060) and factory .020 340 cast pistons # 3621354. It requires a 4.06 - inch diameter bore size and needs some machine work to be used with the 360 crank . It will give a compression ratio of 11.8-to-1 as is , or the top can be cut down up to.080-inch to lower the ratio for pump gas !!!

371 - Cubic Inch "A" engine with 100 % Chrysler parts !!

Very interesting article and some good info coming from the Man ( Tom Hoover ) who managed the Drag Racing programs for Chrysler.

The heart of the 371- incher ( a 360 bored .060) and factory .020 340 cast pistons # 3621354. It requires a 4.06 - inch diameter bore size and needs some machine work to be used with the 360 crank . It will give a compression ratio of 11.8-to-1 as is , or the top can be cut down up to.080-inch to lower the ratio for pump gas !!!