HotRod777

Active Member

So I just picked up an A body overdrive. It was crazy cheap from a guy who was clearing out a basement full of parts that have been sitting for at least 15 years. (Possibly an older family members prior stash) It’s 26 output spline, A tail-housing, it has a shifter mounting plate on it, has a slip yoke included AND a small block OD bell housing. (It does not have shift levers or rods with it) He said “it’s was apart, cleaned, checked years ago and is ready to go”. I though to myself he should have included “I just lost the receipts” in his sales pitch. Lol

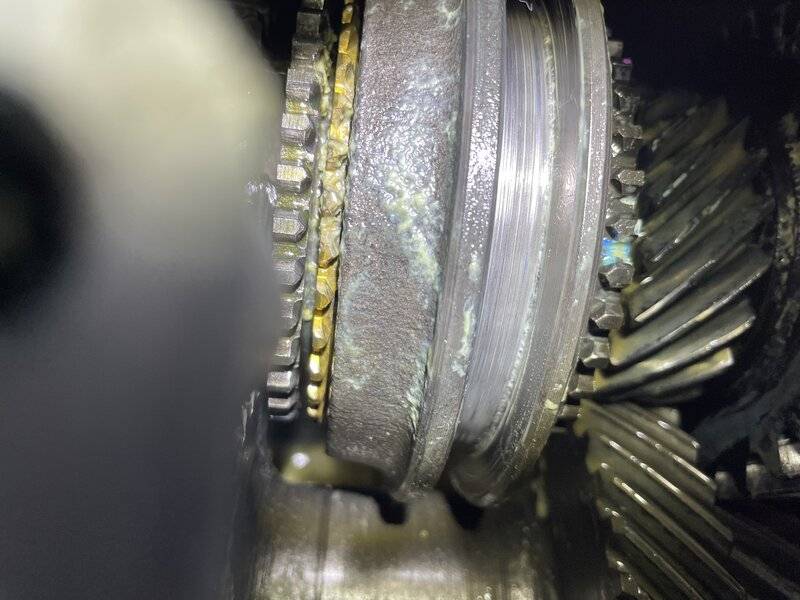

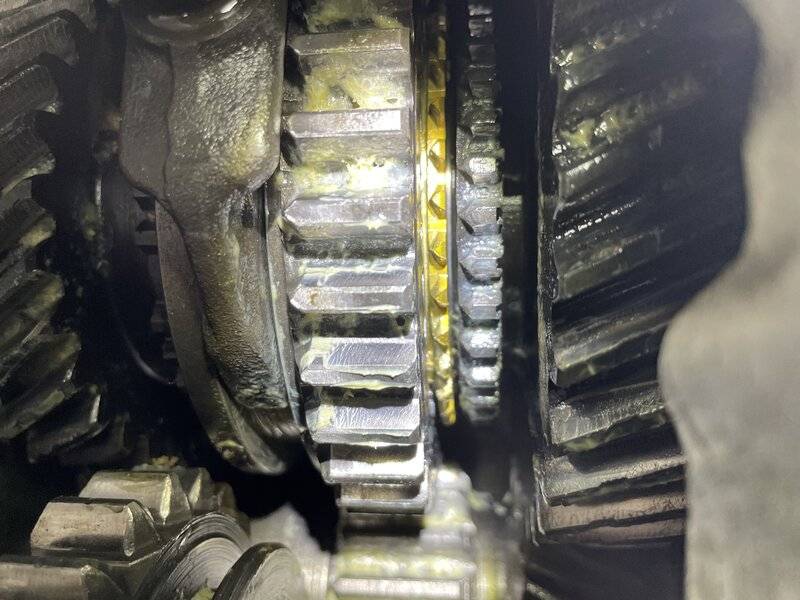

Anyway, I’m not doing the whole swap job without sacrificing a $40 gasket kit to take a look inside. The good news is it WAS actually apart and is still clean and dry inside with clear remnants of white assembly grease. How do the brass rings look to the knowledgeable people here? Would you just replace the seals and gaskets and send it? (The only thing I wouldn’t do is the reverse O ring.. I’ll pray for that little guy and then curse him out when he leaks. Lol.

And a few other questions. Will my 3/4 lever from my current non-OD work when I flip it over? It appears the OD levers has the rectangle register clocked slightly from parallel. And, should I expect to need to lengthen my 3/4 rod?

Thanks for any and all input.

Anyway, I’m not doing the whole swap job without sacrificing a $40 gasket kit to take a look inside. The good news is it WAS actually apart and is still clean and dry inside with clear remnants of white assembly grease. How do the brass rings look to the knowledgeable people here? Would you just replace the seals and gaskets and send it? (The only thing I wouldn’t do is the reverse O ring.. I’ll pray for that little guy and then curse him out when he leaks. Lol.

And a few other questions. Will my 3/4 lever from my current non-OD work when I flip it over? It appears the OD levers has the rectangle register clocked slightly from parallel. And, should I expect to need to lengthen my 3/4 rod?

Thanks for any and all input.