G'day all

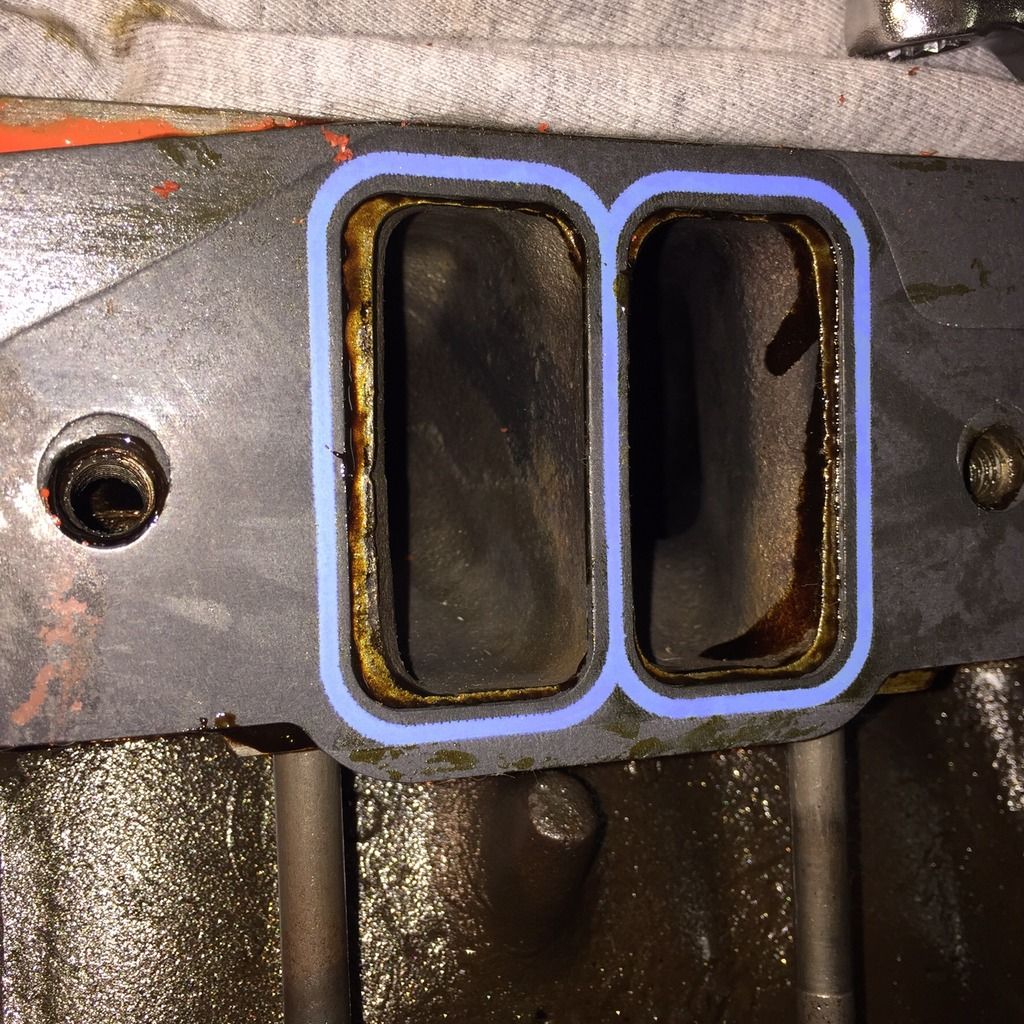

I have a new Edelbrock Performer intake on my 318 with J heads.

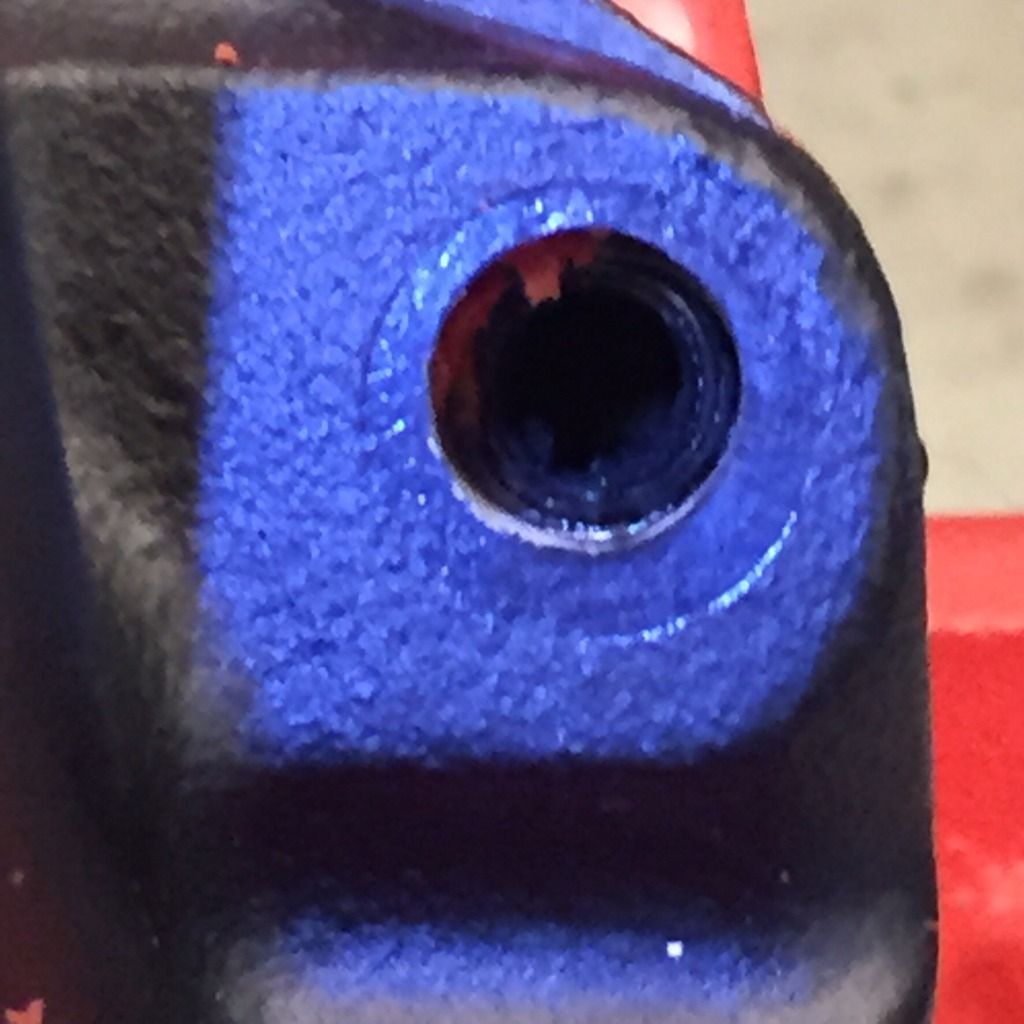

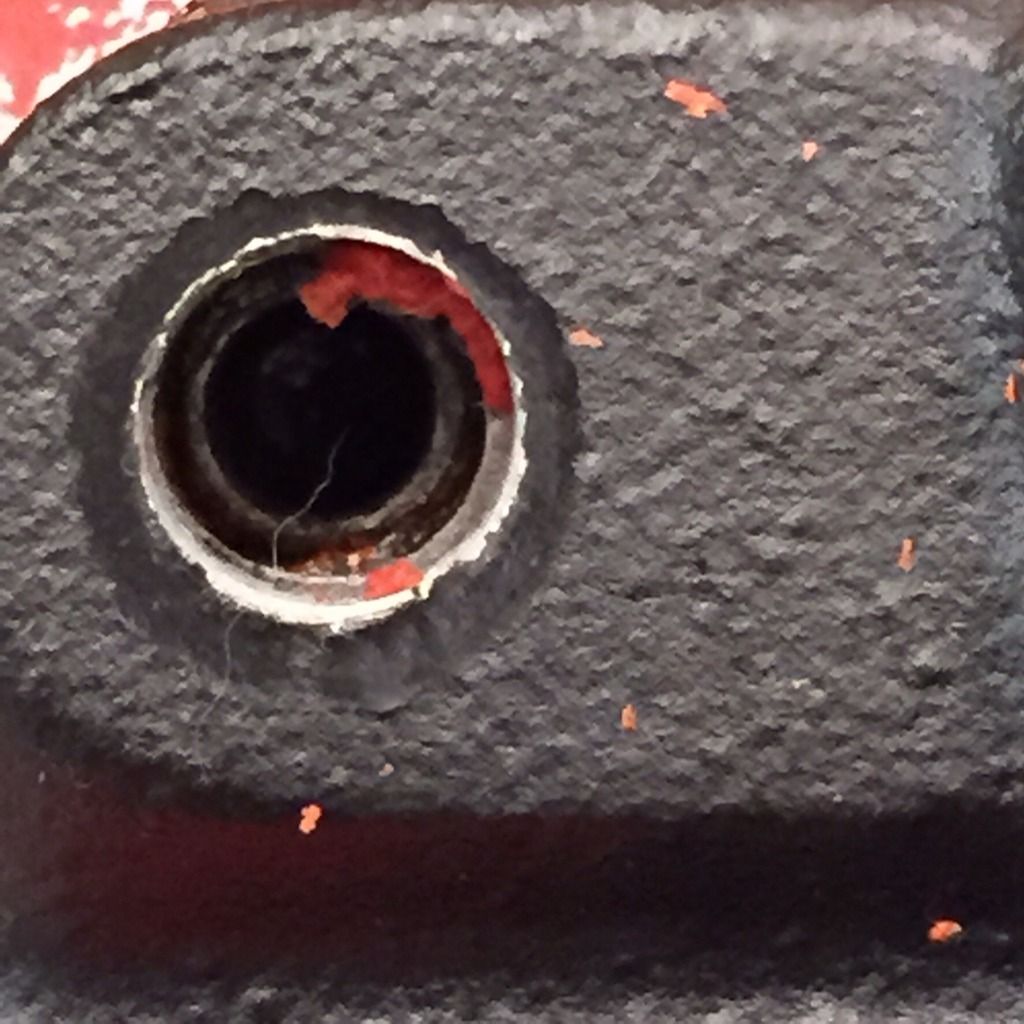

The bolt holes do not line up properly and are very difficult to torque down.

I am thinking I need to mill the manifold but I have no idea by how much. The heads etc were already on the block and I have no idea how much they were machined.

How can I work out how much I need to machine off the manifold?

Regards

Anthony

I have a new Edelbrock Performer intake on my 318 with J heads.

The bolt holes do not line up properly and are very difficult to torque down.

I am thinking I need to mill the manifold but I have no idea by how much. The heads etc were already on the block and I have no idea how much they were machined.

How can I work out how much I need to machine off the manifold?

Regards

Anthony