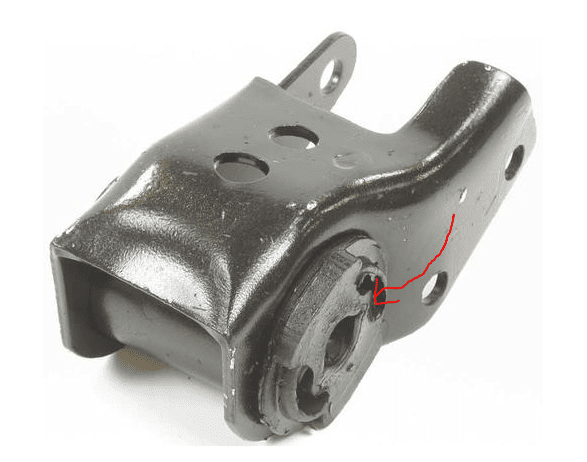

Before my new engine goes in, I am seizing the opportunity to replace the rubber inserts in my motor mounts with urethane pieces. I am working on the '73+ 340/360 style motor mounts that connect the engine block to the K member.

It seemed like a very straight forward job and I didn't anticipate any problems...but these pieces appear to be molded into the bracket in an unexpectedly tenacious fashion. Even after trimming away as much of the material as possible, They resisted the press to the point of bending the sheet metal slightly. They're probably salvageable but to be on the safe side, I have another set of used motor mounts on the way (which will also benefit from the new inserts).

So before I mess up another set of mounts, what's the right way to get those out? I'm sure a torch would do it but I'm hoping there is a trick that will help avoid melting/burning and the associated smoke and mess.

Thanks!

It seemed like a very straight forward job and I didn't anticipate any problems...but these pieces appear to be molded into the bracket in an unexpectedly tenacious fashion. Even after trimming away as much of the material as possible, They resisted the press to the point of bending the sheet metal slightly. They're probably salvageable but to be on the safe side, I have another set of used motor mounts on the way (which will also benefit from the new inserts).

So before I mess up another set of mounts, what's the right way to get those out? I'm sure a torch would do it but I'm hoping there is a trick that will help avoid melting/burning and the associated smoke and mess.

Thanks!