You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'm 3D Printing a set of Dash Panels with Gauges

- Thread starter KevinB

- Start date

-

Thank you for the kind words!This is KILLER! Great stuff and can't wait to see your progress. I have nothing to add other than morale support to your project lol

mcmlvii

Well-Known Member

I'm curious what you use for flatbed temperature when you're printing. The parts I do seem to like the bed kept at 80c for the entire print, to keep from curling the bottom edges. I primarily use PETG.

Still learning it, the software can glitch a bit but I can live with it. Overall I’m liking it. I think it will really come in handy on the tail lightsAnother excellent project Kevin. How do you like the einstar?

I print in ASA and it likes about 90-100c on my printer.I'm curious what you use for flatbed temperature when you're printing. The parts I do seem to like the bed kept at 80c for the entire print, to keep from curling the bottom edges. I primarily use PETG.

How well does the ASA material take to paint?

I really like your design. It looks like something the factory might've actually done, which always integrates better. I have Speedhut gauges for my '82 Imperial project and had them printed in the "correct" '80s font (called Square721 if I recall) just so they wouldn't look completely tacked-on. They didn't quite nail the font, though. I blame myself--I should've provided some artwork to show them what I expected.

I really like your design. It looks like something the factory might've actually done, which always integrates better. I have Speedhut gauges for my '82 Imperial project and had them printed in the "correct" '80s font (called Square721 if I recall) just so they wouldn't look completely tacked-on. They didn't quite nail the font, though. I blame myself--I should've provided some artwork to show them what I expected.

I haven't tried painting it yet, at most I've sanded it smooth and applied epoxy resin to it, both of which worked fine. Online guides say ASA paints just fine like ABS. Thanks, I'm really trying to keep it looking like something that would have come from factory...really confuse the folks at the car shows. I didn't realize Speedhut will work with you on fonts, I might have considered a different one if I had known that, but as it is I'm fine with the Futura that is on there.How well does the ASA material take to paint?

I really like your design. It looks like something the factory might've actually done, which always integrates better. I have Speedhut gauges for my '82 Imperial project and had them printed in the "correct" '80s font (called Square721 if I recall) just so they wouldn't look completely tacked-on. They didn't quite nail the font, though. I blame myself--I should've provided some artwork to show them what I expected.

Ironracer

Gearhead

Rally Style! Sweet! This is some cool stuff Y'all do!that's exactly what I'm doing, my original gauges was the long wide speedo. I'm converting to all circle gauges

They'll pretty-much do anything you want, really. I haven't been to the site in awhile but they had a whole gallery of truly-custom gauges. Based on that, I asked via e-mail. It's been some years, but I think there was a flat setup fee of around $65 and a $20 per-gauge charge.I didn't realize Speedhut will work with you on fonts, I might have considered a different one if I had known that, but as it is I'm fine with the Futura that is on there.

My hacked-up Imperial dash... yes, that's a boost gauge.

Ironracer

Gearhead

That's Cool!They'll pretty-much do anything you want, really. I haven't been to the site in awhile but they had a whole gallery of truly-custom gauges. Based on that, I asked via e-mail. It's been some years, but I think there was a flat setup fee of around $65 and a $20 per-gauge charge.

My hacked-up Imperial dash... yes, that's a boost gauge.

View attachment 1716038054

too funny, I found that Futura Bold was a dead ringer for the font on a 67 Voltage regulatorI'm fine with the Futura that is on there.

There is a type of paint that bonds to plastics at the molecular level. Vinyl seat paint is as close as I have found to date. I bought some years ago to paint a computer case and you had to remove plastic to remove color. Even a dull object only dented the plastic, the color remained.I haven't tried painting it yet, at most I've sanded it smooth and applied epoxy resin to it, both of which worked fine

Honestly I'm just going to have my paint and body guy do it, I'm not disciplined enough to take it on myself, I would screw it upThere is a type of paint that bonds to plastics at the molecular level. Vinyl seat paint is as close as I have found to date. I bought some years ago to paint a computer case and you had to remove plastic to remove color. Even a dull object only dented the plastic, the color remained.

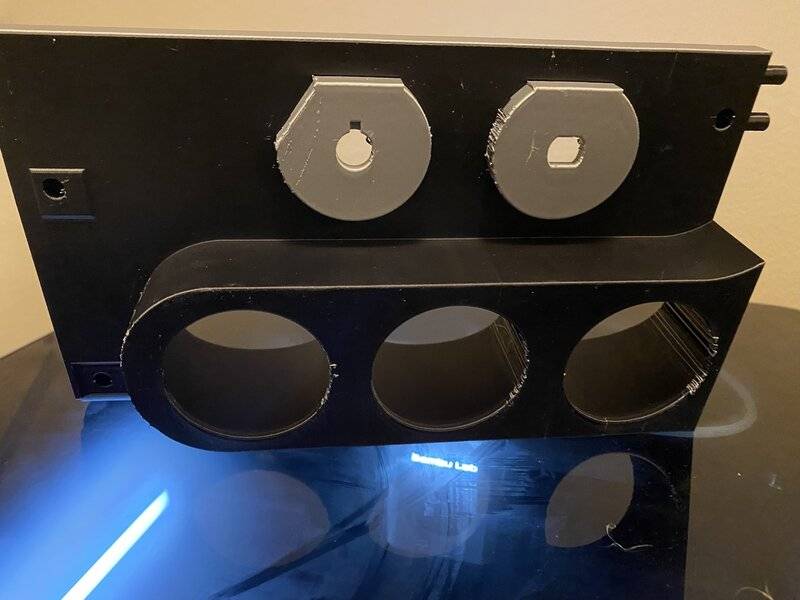

Two steps forward and one step back today. I did some touch up work on the model but decided to hold off on the glove box area until I was able to get some working pieces printed, so I don't have to go back and fix things if there needs to be an adjustment. I did attempt to print the first piece of the cluster, but the print failed due to warping. I did what I could to keep the enclosure temperature high, but the warping occurred anyway. But I did come away with something that I can at least use to test if my model is fitting in the physical hole in the dash, and if the mounting holes are lining up. It does fit, and they do line up, so that's awesome. Now its just down to fine tuning the printing for success. I may add a small temperature controlled heater inside it...and I may turn down the print temperature some, as the hotter you print, the more prone to warping. I also need to look at possibly printing it on its side.

As far as the test piece goes, ignore the wonky shape of the silver part...you're seeing all internal structure, and I have no idea why my software chose that lol.

As far as the test piece goes, ignore the wonky shape of the silver part...you're seeing all internal structure, and I have no idea why my software chose that lol.

72Duster440

Well-Known Member

Looks good, this is an awesome project!

On my LCD resin printer you can not see if it failed till it has come out of the vat. I printed an inch of a part directly to the bottom of the vat once.. I did attempt to print the first piece of the cluster, but the print failed due to warping

So frustrating

Yet it's pretty amazing how things just emerge from the resin goo like magicOn my LCD resin printer you can not see if it failed till it has come out of the vat. I printed an inch of a part directly to the bottom of the vat once.

So frustrating

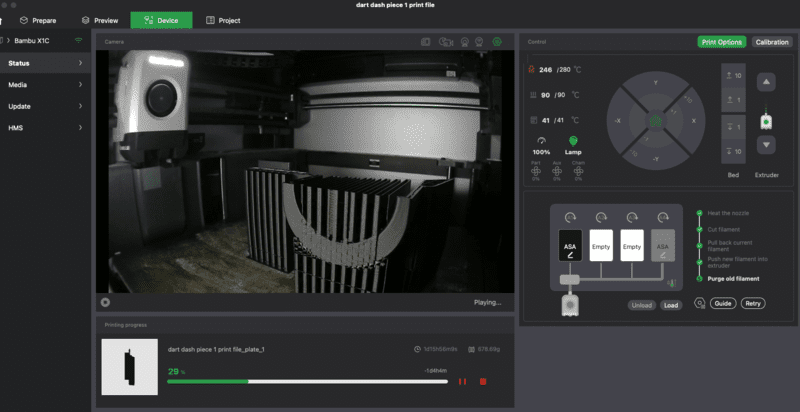

Trying a full print of the first piece on it's side....29% done and looking good so far. 28 hours left to go. I feel like the print will be successful, but due to printing on it's side there's going to have to be some cleanup and sanding at the very least, from the supports. I've had so much trouble with the soluble supports on this print I'm just going back to the old fashioned way of no fancy support material. But that means the surface where the support touch the print is going to be a crapshoot. Anyway, I'll check in on Friday with an update.

Last edited:

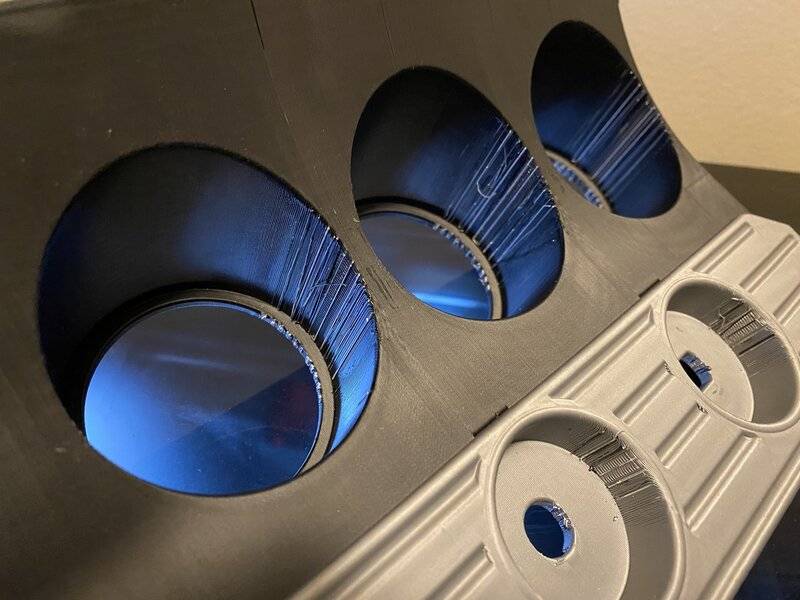

ok first full test print of piece #1 of the dashboard: mixed results. The issues that appeared are #1 warping again, and #2 the surface above the supports.

The warping I was hoping would be eliminated by printing it sideways, but it did still warp a little, not a lot...but enough to make a few cracks appear along layer lines. My options are: Try to install a mini heater in the enclosure to bring the temp up from 44c to around 60-65c, or chop the first piece into two separate pieces. The less you print, the less warp stress exists. This being the largest of the pieces may just be too much material at one time to not warp. If it was just one hairline crack I would be tempted to fill it with epoxy and call it done, as this is gonna have to get sanded and painted in the end.

The second issue is the rough surface where the top of the supports were. I can fix this if I do a bunch of testing and adjusting the support setting until it's dead on, or figuring out the issue with the support filament and how to better use it. If I can print it on its back instead of it's side, the issue moves to an area I don't care about, so in the end I may end up using all of these fixes...smaller part to print, more heat in the chamber, printing on it's back, and using the support filament.

Either way this print has also shown me I need to ventilate the space, so I've got to spend about $250 in supplies to vent the room with a fan going into the attic. Not a hard project, but it's going to cost me a few days. Anyway, in the end I will just keep trying different things until the print is right, so it's a matter of patience. By the way, the way this piece fits into the dashboard cutout is phenomenal...it practically holds itself in there with a bit of friction.

The warping I was hoping would be eliminated by printing it sideways, but it did still warp a little, not a lot...but enough to make a few cracks appear along layer lines. My options are: Try to install a mini heater in the enclosure to bring the temp up from 44c to around 60-65c, or chop the first piece into two separate pieces. The less you print, the less warp stress exists. This being the largest of the pieces may just be too much material at one time to not warp. If it was just one hairline crack I would be tempted to fill it with epoxy and call it done, as this is gonna have to get sanded and painted in the end.

The second issue is the rough surface where the top of the supports were. I can fix this if I do a bunch of testing and adjusting the support setting until it's dead on, or figuring out the issue with the support filament and how to better use it. If I can print it on its back instead of it's side, the issue moves to an area I don't care about, so in the end I may end up using all of these fixes...smaller part to print, more heat in the chamber, printing on it's back, and using the support filament.

Either way this print has also shown me I need to ventilate the space, so I've got to spend about $250 in supplies to vent the room with a fan going into the attic. Not a hard project, but it's going to cost me a few days. Anyway, in the end I will just keep trying different things until the print is right, so it's a matter of patience. By the way, the way this piece fits into the dashboard cutout is phenomenal...it practically holds itself in there with a bit of friction.

Do you have a large enough bed to print on the diagonal?

There was a video I saw that talked about the optimum angle to print for strength / outcome. The angle was between 35 and 55 deg. IIRC

There was a video I saw that talked about the optimum angle to print for strength / outcome. The angle was between 35 and 55 deg. IIRC

Not diagonally in the x/y plane, but I may see about tilting it on the x axis so that it still prints sort of flat, but may not need so many supportsDo you have a large enough bed to print on the diagonal?

There was a video I saw that talked about the optimum angle to print for strength / outcome. The angle was between 35 and 55 deg. IIRC

-

Similar threads

- Replies

- 7

- Views

- 415

- Replies

- 32

- Views

- 2K

- Replies

- 31

- Views

- 1K