I have a question for some of you out there that perhaps know more about this one than me. When I got my car, I noticed it had some bolts attaching the inner fenders to the u-shaped brace that is underneath it that the front shock absorber attaches to. As this was always a drag race car, and typically launched with the front end a bit in the air (ran 10.60's), I'm wondering if this is a common thing to do to help when the front end comes back down. Here's a shot of the RH inner fender where you can see the bolt on the vertical as well as the horizontal part of the inner fender.

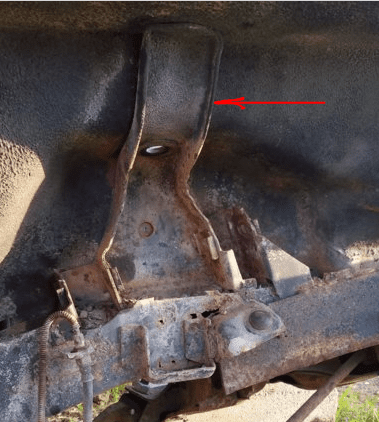

This car doesn't have any damages or anything so I'm just curious if this is something anyone has seen done before. When I look in the fenderwell, that shock brace really just seems to be hanging in mid-air so perhaps it could use some "help?" I took a snip of a pic of another members car on here just to show the shock brace I'm talking about:

I'm cleaning up/painting the engine compartment and trying to decide if I should put those attaching bolts back in or just weld up the offending bolt holes and leave it as it was originally when built. Also, is that shock brace actually attached underneath to the inner fender by design somehow (where you can't see it)? Seems like it would be pretty flimsy without some type of attachment.

Thx for your input!!

This car doesn't have any damages or anything so I'm just curious if this is something anyone has seen done before. When I look in the fenderwell, that shock brace really just seems to be hanging in mid-air so perhaps it could use some "help?" I took a snip of a pic of another members car on here just to show the shock brace I'm talking about:

I'm cleaning up/painting the engine compartment and trying to decide if I should put those attaching bolts back in or just weld up the offending bolt holes and leave it as it was originally when built. Also, is that shock brace actually attached underneath to the inner fender by design somehow (where you can't see it)? Seems like it would be pretty flimsy without some type of attachment.

Thx for your input!!