You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

moog problem solvers creating problems....

- Thread starter shep76

- Start date

-

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 9,522

- Reaction score

- 5,049

Are those offset bushings or standard ?

shep76

Well-Known Member

That’s helpful. Thanks. Yep, one of mine is wider than the other three.

I don't know how relevant this is, but a while back I replaced the lower control arm bushings on my 65 Barracuda. The Moogs did not fit! The lip was too thick and the radius under it to wide to allow them to seat fully. I switched to Delco, they were fine.

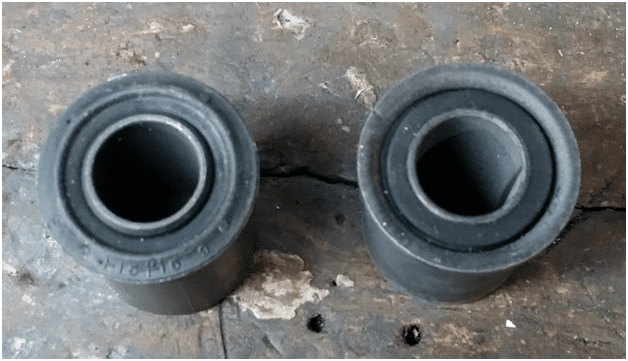

Moog on the left, Delco on the right.

Here's the Moog in the control arm.

I don't know where Moogs are made these days, nor if they still have this problem, but it appears that Moog quality cannot be counted on anymore.

Moog on the left, Delco on the right.

Here's the Moog in the control arm.

I don't know where Moogs are made these days, nor if they still have this problem, but it appears that Moog quality cannot be counted on anymore.

fetch the big all 16ths from the lower drawer of the tool box and adjust it to just fit the tabs, then just give it a 'lil pull out.I’m calling it. Its off by a full quarter inch. This isn’t going to just be a little tappy tapper with a hammer. I’m going to try another bushing.

revel in your mechanical magnificence, finish the beer you started half an hour ago and forgot about and then do the other side.

shep76

Well-Known Member

It’s date night so no beer, Margaritas…. What is a big all 16ths?? It’s the washers/ferrels. Two of them just have way more crown than the others so they stick out further.fetch the big all 16ths from the lower drawer of the tool box and adjust it to just fit the tabs, then just give it a 'lil pull out.

revel in your mechanical magnificence, finish the beer you started half an hour ago and forgot about and then do the other side.

mcodecuda

Senior Member

By chance do you have the other side of the control arm installed between the tabs? If so remove that side and install the ends of the control arms simultaneously by tapping one side and then the other.Anyone else experience this? I installed the K7103's and now my UCA doesn't fit. The bushings are fully seated and I've tried to squish the ferrels on tighter but no luck.... Anyone have any fixes for this?

View attachment 1716218360

65TerrorCuda

Well-Known Member

My Moog problem makers are .014" larger diameter than the ones that came out of the arm. That's too much press fit for me so I belt sanded them down before deciding on o.e. style and those ones were oversized too.

TrailBeast

AKA Mopars4us on Youtube

A putty knife is your friend.

Put it between the two parts and ramp it in there.

Put it between the two parts and ramp it in there.

michiganpat

Well-Known Member

my OEM bushings had washers pressed in them that looked like this:So.....and I'm not arguing here, just posing a question. Why were they not used from the factory? Of all of the upper arm bushings I've replaced, not a one had those washers originally.

I just installed my control arms this past weekend with the moog bushings, had a little trouble on the passengers side getting it in. I had to get the front and back in at basically the same time. start the front just enough to catch it, then try catch the back. I needed some slight persuasion with a deadblow/rubber mallet to get it in.

shep76

Well-Known Member

I finally got mine in. I also had to use some persuasion. Forcing in a suspension components seemed odd to me but it seems you guys all had to do the same so hopefully it will be ok. I suppose the test drive will be the judge.

jeff alder

Well-Known Member

oj simpsond photo with glove - Bing If OJ can do it....

remytherat

Well-Known Member

a lil improvised percussion never hurt anythingI finally got mine in. I also had to use some persuasion. Forcing in a suspension components seemed odd to me but it seems you guys all had to do the same so hopefully it will be ok. I suppose the test drive will be the judge.

Just think of how a mechanic/technician back in the day at a dealership working for flat rate did it!I finally got mine in. I also had to use some persuasion. Forcing in a suspension components seemed odd to me but it seems you guys all had to do the same so hopefully it will be ok. I suppose the test drive will be the judge.

Dartswinger70

Well-Known Member

\Spread the attachment points wider, tightening the bolts pulls it back in...I was just a bit hesitant to start pounding on it... I didn't want to bend the attachment point...

QuickDart360

Well-Known Member

I just recently installed same problem solver bushings. All I did was use a rubber mallet to open/spread outer tabs out. In went control arms. Still went in snug but their in!

-

Similar threads

- Replies

- 16

- Views

- 977

- Replies

- 73

- Views

- 7K

- Replies

- 2

- Views

- 611