myasylum

Well-Known Member

O.k. I did some reading on this before I started. I did see some instructions for 72 and under Darts. I was using that as an example but even with that it didn't really go into detail of where to start with drilling the 8 holes!

So I just dug in, and got down and dirty, I thought I'd post this for others having the same questions in the future. If for some reason this seems incorrect, I'm sorry in advance, but this is what worked for me, and believe me, it took awhile. I'm no expert body man.

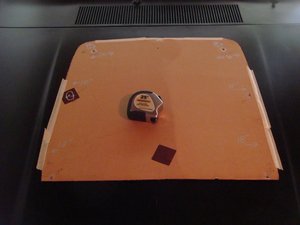

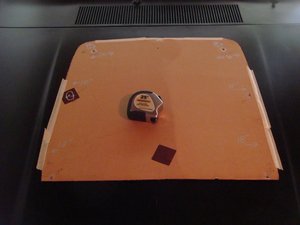

First I made a template. I just took a large piece of cardboard, and set the scoop on top of the cardboard. I pushed down a bit on the scoop itself so it left indentations on the cardboard itself. Then I traced around the scoop and cut it out.

I then laid the cardboard on the hood...

I then found all measurements, from the holes for the studs out to the edge of the hood. This might seem obvious, but this is how I measured all

sides with measuring tape.

Then this is the measurements I found.

3 1/4 from the top of the hood to the top of the cardboard (which was cut to the outline of the scoop, this also follows the stock positioning for Darts as well)

6 7/8" from the two side studs (holes) to the end of the hood.

20 3/8" to each side from the same studs (holes) to the side of the hood.

18" to each side from the center studs (holes) to the sides of the hood.

18" to each side from the front two studs (holes) to sides of the hood.

Now for the front stud I ran out of cardboard, but I figured out that the studs are 22" apart, so the obviously the center is a 11" then with a straight edge, going across the studs, and measuring up to the top stud, it is 2". That is where I placed my final front center stud. I also used tape to hold the cardboard in place while using marker to mark my spot. (Remember as Indiana Jones says, "X never marks the spot"

(As a word of advice before you start drilling, be careful. If your drill slips it will wonder off, you can easily loose your drilling point and and sucks! Not to mention scratch the paint on your freshly painted car. Then you'll end up cursing and wanting to kill people. Don't ask me how I know this! :angryfir

Now, once holes are drilled we have another issues. Because we had to drill through the cross members of the hood, the studs don't fit through the cross members on the INSIDE of the hood. So You have to buy one of these thingamabobdohickys... (Kind of looks like Satan)

This will enlarge your hole (I said "hole") so you can get at the studs, and fit a socket in there to tighten the nuts. I used a 1 1/8" 29mm thingamabobdohicky.

I hope this looks straight to you, because it does me. Not only that, but I think I'm sober.

Just a couple things to mention, I did go to the local hardware store and buy rubber O-Rings for the studs, just for rust reasons on the hood, tiring to keep the water out. Also I used some primer, to cover any bare metal so it wouldn't rust. I don't know if this is something you need to do, but it seemed like a good idea too me.

Also make sure your drill is fully charged, or use a corded power drill, especially for the extra holes inside the hood. It's a bummer when you start a project and realizes your drill is only half charged!

O.k. I'm done. I hope this is useful for somebody?

Thanks.

So I just dug in, and got down and dirty, I thought I'd post this for others having the same questions in the future. If for some reason this seems incorrect, I'm sorry in advance, but this is what worked for me, and believe me, it took awhile. I'm no expert body man.

First I made a template. I just took a large piece of cardboard, and set the scoop on top of the cardboard. I pushed down a bit on the scoop itself so it left indentations on the cardboard itself. Then I traced around the scoop and cut it out.

I then laid the cardboard on the hood...

I then found all measurements, from the holes for the studs out to the edge of the hood. This might seem obvious, but this is how I measured all

sides with measuring tape.

Then this is the measurements I found.

3 1/4 from the top of the hood to the top of the cardboard (which was cut to the outline of the scoop, this also follows the stock positioning for Darts as well)

6 7/8" from the two side studs (holes) to the end of the hood.

20 3/8" to each side from the same studs (holes) to the side of the hood.

18" to each side from the center studs (holes) to the sides of the hood.

18" to each side from the front two studs (holes) to sides of the hood.

Now for the front stud I ran out of cardboard, but I figured out that the studs are 22" apart, so the obviously the center is a 11" then with a straight edge, going across the studs, and measuring up to the top stud, it is 2". That is where I placed my final front center stud. I also used tape to hold the cardboard in place while using marker to mark my spot. (Remember as Indiana Jones says, "X never marks the spot"

(As a word of advice before you start drilling, be careful. If your drill slips it will wonder off, you can easily loose your drilling point and and sucks! Not to mention scratch the paint on your freshly painted car. Then you'll end up cursing and wanting to kill people. Don't ask me how I know this! :angryfir

Now, once holes are drilled we have another issues. Because we had to drill through the cross members of the hood, the studs don't fit through the cross members on the INSIDE of the hood. So You have to buy one of these thingamabobdohickys... (Kind of looks like Satan)

This will enlarge your hole (I said "hole") so you can get at the studs, and fit a socket in there to tighten the nuts. I used a 1 1/8" 29mm thingamabobdohicky.

I hope this looks straight to you, because it does me. Not only that, but I think I'm sober.

Just a couple things to mention, I did go to the local hardware store and buy rubber O-Rings for the studs, just for rust reasons on the hood, tiring to keep the water out. Also I used some primer, to cover any bare metal so it wouldn't rust. I don't know if this is something you need to do, but it seemed like a good idea too me.

Also make sure your drill is fully charged, or use a corded power drill, especially for the extra holes inside the hood. It's a bummer when you start a project and realizes your drill is only half charged!

O.k. I'm done. I hope this is useful for somebody?

Thanks.