articcolds

Well-Known Member

Hello

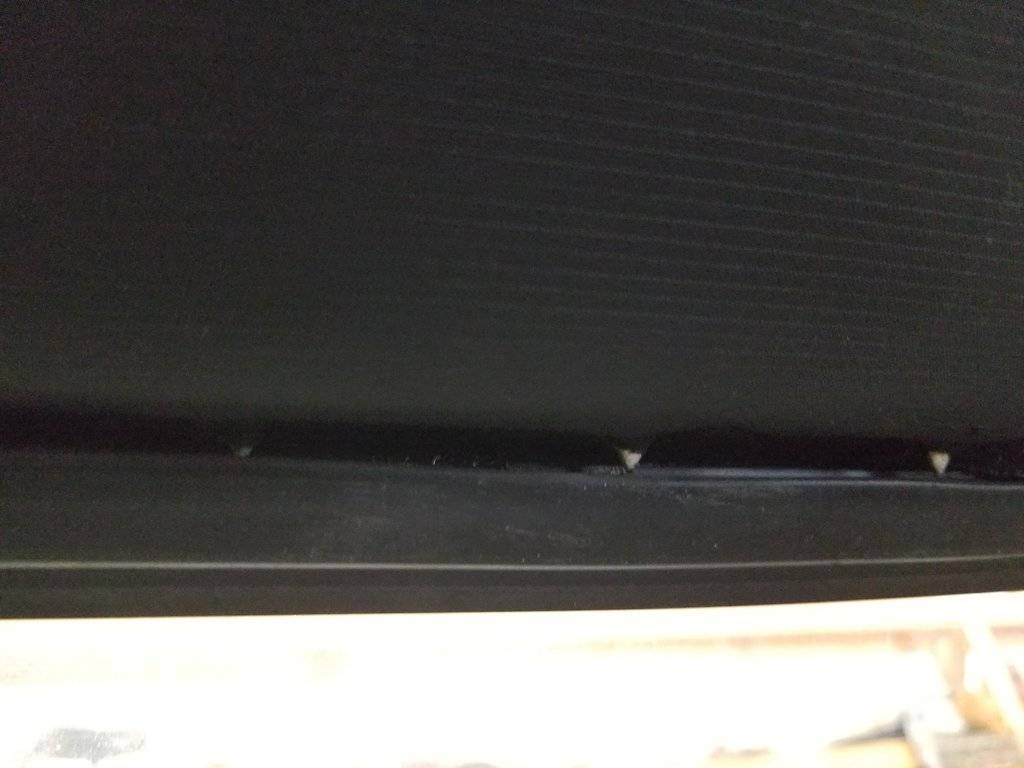

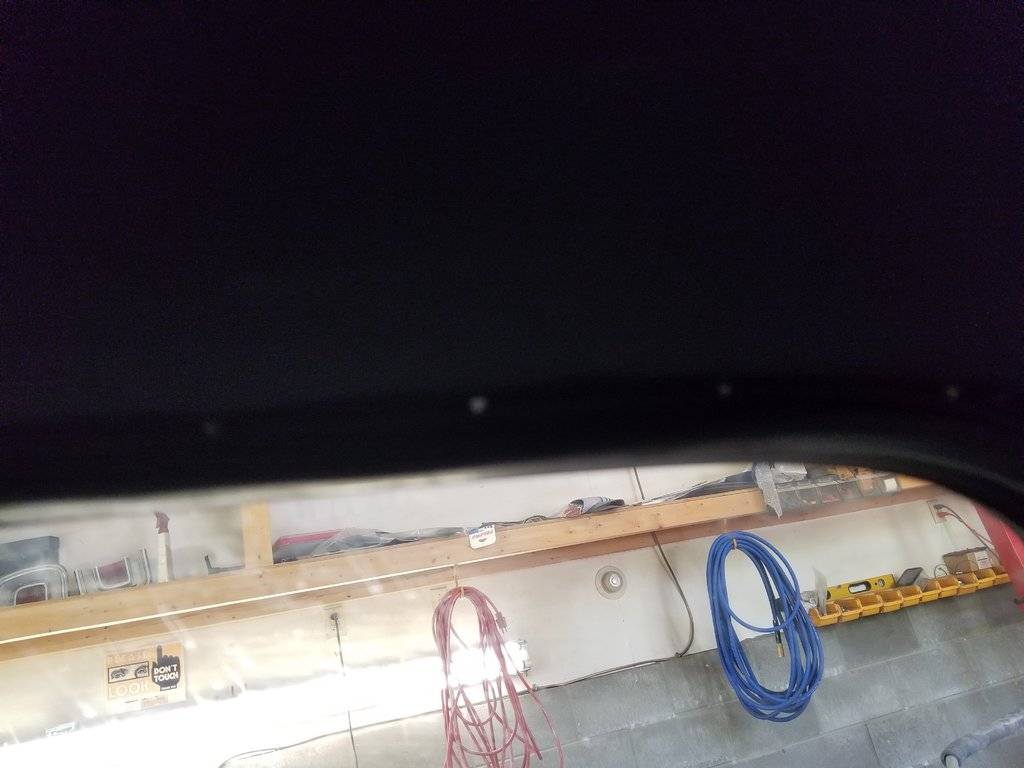

I haven't posted something in while and could really use some help . I have a 1968 Cuda notchback. I have had to purchase a new rear window since old one is pretty scratched up. The weather strip doesn't seem to roll down enough to cover the headliner window transition point at all. I have tried 2 weatherstrippings . Today I even tried to use the original window and it didn't change much. I took out the headliner after install and put 1/2 foam to help push headliner out more to seal against inside lip of weatherstripping. It just doesn't fit correct . Being there are few options available I can't be the only one that is having this trouble . I just don't know what to do or how to solve this issue.When I was building the car nothing was damage or done to the pinch weld around window. Any help would be great it's become quite a headache

I haven't posted something in while and could really use some help . I have a 1968 Cuda notchback. I have had to purchase a new rear window since old one is pretty scratched up. The weather strip doesn't seem to roll down enough to cover the headliner window transition point at all. I have tried 2 weatherstrippings . Today I even tried to use the original window and it didn't change much. I took out the headliner after install and put 1/2 foam to help push headliner out more to seal against inside lip of weatherstripping. It just doesn't fit correct . Being there are few options available I can't be the only one that is having this trouble . I just don't know what to do or how to solve this issue.When I was building the car nothing was damage or done to the pinch weld around window. Any help would be great it's become quite a headache