on 1971 340 ci do not have old thrust plate and bolts so I ordered new type with chain tensioner my question how does the chain get oil to it and should I seal the 2 oils holes behind new plate also should I seal Thrust plate to block .Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oiling timing chain

- Thread starter jack colv

- Start date

-

Just from a drip plate bolted to the front of the camshaft thrust plate. A lot of people drill a small hole through the thrust plate right in front of one of the main oil galleys to get pressurized oil blasting on the back of the camshaft sprocket. Works good.

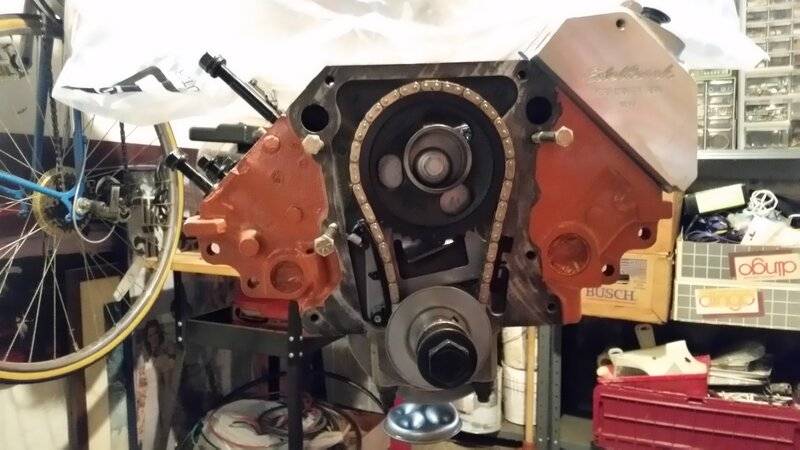

The first picture is the early way the second is the later.

I use the later method with the dripper but install the bolt with the hole in the upper left corner.

The tensioner is only a bandaid for cheap chains. If you need a tensioner then you bought a cheap chain like they installed on the the motors they came with in the 90's. A tensioner is just another part to fail.

I use the later method with the dripper but install the bolt with the hole in the upper left corner.

The tensioner is only a bandaid for cheap chains. If you need a tensioner then you bought a cheap chain like they installed on the the motors they came with in the 90's. A tensioner is just another part to fail.

So, I guess you would leave One of the Galley Plugs Out behind the Plate too?

dartfreak75

Restore it, Dont part it!

I drilled a hole through the cam plate and then drilled a small hole into the plug behind it. Just make sure you drill the hole in the plate smaller than the outside dia of the plug. You don't want it coming out.

I've seen precious few that had plugs at all. Most I've seen used the cam thrust plate to block the oil galleys off.So, I guess you would leave One of the Galley Plugs Out behind the Plate too?

Just like that^^^^^I drilled a hole through the cam plate and then drilled a small hole into the plug behind it. Just make sure you drill the hole in the plate smaller than the outside dia of the plug. You don't want it coming out.

View attachment 1715841694

The factory drip oiling is minimal at best for a stock engine, much less a high performance one. Nice job, Kevin!

To much oil on the chain it just starts carrying it around. true roller chains don't need much oil. Just keep the chain wet.

Thanks for the response I agree I did want like using thrust plate with tensioners but that is all I can find. What size are the soft plugs for oil holes as the block I am working on does not have them

The oil galley plugs are not required. The thrust plate blocks them off.

Don't forget to soak the chain in oil before install. Added protection on initial fire-up.

It totally depends on which double roller chain it is. Some work with the tensioner and some not so well.I am not 100% on this but I remember something about NOT using a tensioner with a double roller chain set.

72Dart6pack

Harder Better Faster Stronger.

I went with the new style on my 408.

Well, I for one like the idea of pressurized oil to the chain. It's not like it's gonna hurt anything and the only possible effect would be positive.

No way would I use a tensioner. A quality chain and no need. What is the wear area on the tensioner made of? And where does it go?

Rat Bastid

Dunamis Metron

No way would I use a tensioner. A quality chain and no need. What is the wear area on the tensioner made of? And where does it go?

The tensioner is made of UHMW. It work hardens. Think about all the SOHC and DOHC junk out there using tensioners and roller timing chains. No sense to not use a tensioner.

I agree with Steve, buy a good quality timing chain and gear set- up to start with. And a course one with multiple keyways, you are going to check valve timing right and make the necessary adjustments right? This picture clearly shows the wear the rubbing blocks left by the chain, this only in about three years of cars shows and occasional drive. While I do understand the wear marks on the pads, but there small chunks missing in the plastic grooves the timing chain have left…not so great.

The tensioner itself is well designed and will work great if used with the correct chain.. a link chain or “silent chain”. This is nicely illustrated in post # 14 the pads now have the full backing of the chain instead of 4 rows of timing chain links.

Needles to say this set up will be going into the trash bin, and I will be going with the stock cam plate and oil baffle plate and a hole in the bolt configuration.

Merry Christmas and a Happy New Year.

The tensioner itself is well designed and will work great if used with the correct chain.. a link chain or “silent chain”. This is nicely illustrated in post # 14 the pads now have the full backing of the chain instead of 4 rows of timing chain links.

Needles to say this set up will be going into the trash bin, and I will be going with the stock cam plate and oil baffle plate and a hole in the bolt configuration.

Merry Christmas and a Happy New Year.

Last edited:

Mopar44134

Well-Known Member

I thought adding a tensioner helps keep timing as consistent as possible. Even good chains have a little bit of slop. But i guess a little bit of slop isnt a concern. I've read people adding a tensioner from a 3.9 v6. Those probably have the quiet nylon chains.

I've seen other pics of similar shitty tensioners. That's enuf for me to say nope. Thousands of perfectly good running ones without one.

The tensioner is made of UHMW. It work hardens. Think about all the SOHC and DOHC junk out there using tensioners and roller timing chains. No sense to not use a tensioner.

I agree with Steve, buy a good quality timing chain and gear set- up to start with. And a course one with multiple keyways, you are going to check valve timing right and make the necessary adjustments right? This picture clearly shows the wear the rubbing blocks left by the chain, this only in about three years of cars shows and occasional drive. While I do understand the wear marks on the pads, but there small chunks missing in the plastic grooves the timing chain have left…not so great.

The tensioner itself is well designed and will work great if used with the correct chain.. a link chain or “silent chain”. This is nicely illustrated in post # 14 the pads now have the full backing of the chain instead of 4 rows of timing chain links.

Needles to say this set up will be going into the trash bin, and I will be going with the stock cam plate and oil baffle plate and a hole in the bolt configuration.

Merry Christmas and a Happy New Year.

View attachment 1715842074

Running a Mopar Performance chain tensioner with a Summit billet chain set. After a few years (albeit low mileage, maybe 8000 miles?) and then a cam swap the pad the chain rides on only showed scuff marks, no gouges, signs of melting, chunking, chipping. fractures or fissures, hair line cracks lifting or looseness. I don’t attribute it to just rare luck or being an exception to the rule. IMO it’s the opposite. It’s typical and to be expected. Unfortunately people have had issues, but fortunately they are in the minority, only getting amplified on various forums

thesiren74

Well-Known Member

Yeah my brother used one on his 408. After he blew it up we looked at it it looked fine.Running a Mopar Performance chain tensioner with a Summit billet chain set. After a few years (albeit low mileage, maybe 8000 miles?) and then a cam swap the pad the chain rides on only showed scuff marks, no gouges, signs of melting, chunking, chipping. fractures or fissures, hair line cracks lifting or looseness. I don’t attribute it to just rare luck or being an exception to the rule. IMO it’s the opposite. It’s typical and to be expected. Unfortunately people have had issues, but fortunately they are in the minority, only getting amplified on various forums

Scody21

Just send it

I’m running a Pro Gear chain that I got from Hughes with a cloyes branded tensioner. When I call Hughes, Dave said to run the tensioner. I Put them in back in July and have about 15 hours on the motor since. Motor is coming out in the next few weeks for a head/cam swap refresh. I’ll post some pick of the chain and tensioner.

We're gettin sidetracked talking about tensioners. The thread is about chain oiling.

Scody21

Just send it

We're gettin sidetracked talking about tensioners. The thread is about chain oiling.

yeah yeah. I used the dripper bolt with the tensioner…

-