MDchanic

Connoisseur d'Junque

I was out looking at the '64 Dart yesterday, standing in the cold in the barn, sort of thinking about what needed to be done on it, when my eyeballs rolled over the windshield washers, which don't work.

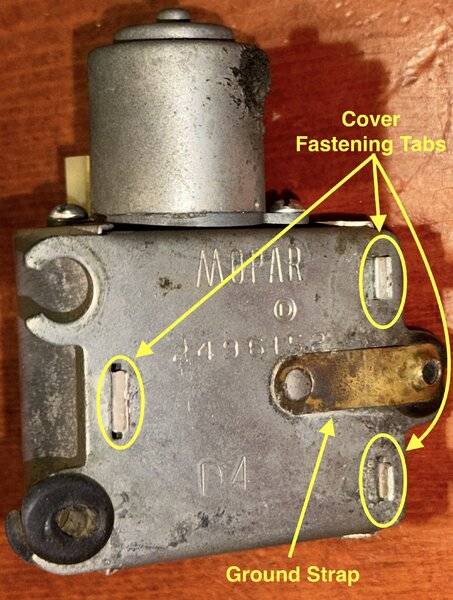

Now, this car has the first series electric washer pump (available from about mid-'64 through '66 or '67, if I recall), which is a metal pump mounted to the fender with three screws, fed by a rubberized bag reservoir, with a single outlet and a single power wire. The pump was used by Chrysler for all its vehicles at some point between about 1960 and 1968. Its part number is 2496152, and it's available re-po'd new from a variety of sellers from $35 to $70. The same pump was used by Frod during the same period, and is also available from Frod suppliers.

I looked at that pump on the fender and said, "Hell, It'll just take a minute to take that off so I can replace it with a generic auto parts store pump for $15."

Welllll... Once I had the reservoir and the pump off, I had to test it, right?

Jumper to the battery and the little motor went "Ermm." like it wanted to turn.

Might as well take a look inside and see what's keeping it from turning...

So...

You remove the outside cover by prying three retaining tabs straight and pulling it off (it's aluminum, so the obsessive can polish it to a bright shine if they wish).

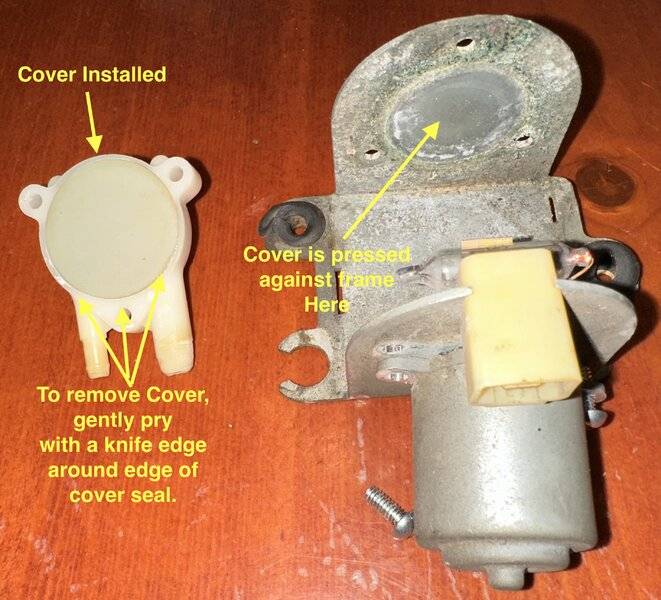

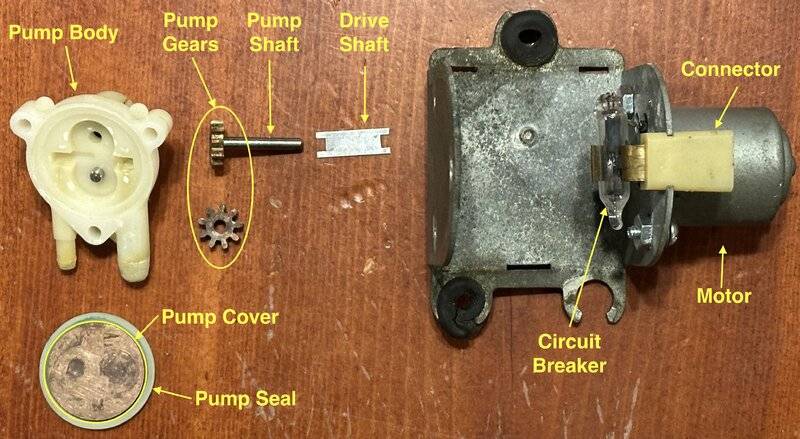

With the cover off, you can see the little plastic pump body and the flat stainless steel strip that serves as a driveshaft, and also the thermal circuit breaker (for in case the washer fluid is frozen and the motor won't turn), which looks like a little neon light bulb.

[The screws and nuts are mine – I didn't take any pictures as I avidly tore it apart.]

Once open, I ground the heads off of the two rivets holding the motor to the frame and the three retaining the pump body.

The pump cover is a copper plated (maybe solid copper?) slug about the size of a quarter, and is attached to the pump body with, of all things, a big round sticker made out of a slightly foamy material.

The sticker is in turn held on by being sandwiched between the pump body and the frame.

To remove the pump cover, just go around the outside edge of the sticker with a sharp-ish blade and gently pry the edges up, then the sticker and the cover it's attached to can just be pulled off.

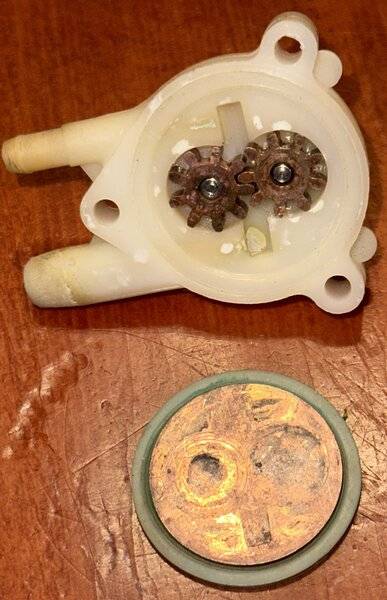

Underneath the cover, you'll find a simple gear pump.

Mine was greenish and gunky, so I soaked it in Vinegar for an hour or so, and toothbrushed everything a couple of times in the process, then washed it all with dish detergent.

It came completely clean with practically no effort.

Reassembly is, as they say, the reverse of assembly, except you've got to juggle that @#$% driveshaft bit into two tiny grooves and keep it there.

I used #6-32 screws I had lying around, and had to chase most of the holes a tiny bit with a 9/64" (I think) drill bit in a screwdriver handle attachment.

I applied a tiny bit of clear plumbing silicone around the adhesive edges of the pump cover retaining sticker before screwing the pump to the frame. We'll see if that works.

So that's all there is to it. I was about to throw this out, but now, with maybe an hour's work, it should work fine, and, if all goes well, I saved myself a few bucks.

I'm dying to test it on the actual washer nozzles, but it's the middle of winter, and I don't want to risk anything freezing and breaking.

By the way, anyone have any suggestions for repairing small cracks in the front of the bag, on either side of the reservoir filler? They won't affect anything, but, you know, it'd be nice to know they weren't there.

Good luck, all, and I hope all of your projects are going well!

– Eric

Now, this car has the first series electric washer pump (available from about mid-'64 through '66 or '67, if I recall), which is a metal pump mounted to the fender with three screws, fed by a rubberized bag reservoir, with a single outlet and a single power wire. The pump was used by Chrysler for all its vehicles at some point between about 1960 and 1968. Its part number is 2496152, and it's available re-po'd new from a variety of sellers from $35 to $70. The same pump was used by Frod during the same period, and is also available from Frod suppliers.

I looked at that pump on the fender and said, "Hell, It'll just take a minute to take that off so I can replace it with a generic auto parts store pump for $15."

Welllll... Once I had the reservoir and the pump off, I had to test it, right?

Jumper to the battery and the little motor went "Ermm." like it wanted to turn.

Might as well take a look inside and see what's keeping it from turning...

So...

You remove the outside cover by prying three retaining tabs straight and pulling it off (it's aluminum, so the obsessive can polish it to a bright shine if they wish).

With the cover off, you can see the little plastic pump body and the flat stainless steel strip that serves as a driveshaft, and also the thermal circuit breaker (for in case the washer fluid is frozen and the motor won't turn), which looks like a little neon light bulb.

[The screws and nuts are mine – I didn't take any pictures as I avidly tore it apart.]

Once open, I ground the heads off of the two rivets holding the motor to the frame and the three retaining the pump body.

The pump cover is a copper plated (maybe solid copper?) slug about the size of a quarter, and is attached to the pump body with, of all things, a big round sticker made out of a slightly foamy material.

The sticker is in turn held on by being sandwiched between the pump body and the frame.

To remove the pump cover, just go around the outside edge of the sticker with a sharp-ish blade and gently pry the edges up, then the sticker and the cover it's attached to can just be pulled off.

Underneath the cover, you'll find a simple gear pump.

Mine was greenish and gunky, so I soaked it in Vinegar for an hour or so, and toothbrushed everything a couple of times in the process, then washed it all with dish detergent.

It came completely clean with practically no effort.

Reassembly is, as they say, the reverse of assembly, except you've got to juggle that @#$% driveshaft bit into two tiny grooves and keep it there.

I used #6-32 screws I had lying around, and had to chase most of the holes a tiny bit with a 9/64" (I think) drill bit in a screwdriver handle attachment.

I applied a tiny bit of clear plumbing silicone around the adhesive edges of the pump cover retaining sticker before screwing the pump to the frame. We'll see if that works.

So that's all there is to it. I was about to throw this out, but now, with maybe an hour's work, it should work fine, and, if all goes well, I saved myself a few bucks.

I'm dying to test it on the actual washer nozzles, but it's the middle of winter, and I don't want to risk anything freezing and breaking.

By the way, anyone have any suggestions for repairing small cracks in the front of the bag, on either side of the reservoir filler? They won't affect anything, but, you know, it'd be nice to know they weren't there.

Good luck, all, and I hope all of your projects are going well!

– Eric