Daves69

Well-Known Member

Don't ya' love when you're cutting some steel and your machine craps out on ya'?

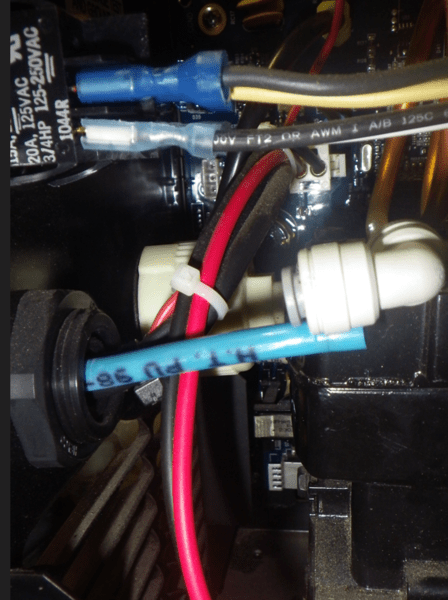

I bought my Hobart 250 ci with internal compressor maybe 8 years ago. Worked fine up till a couple days ago.

Finished a cut, tried to start another, no air.

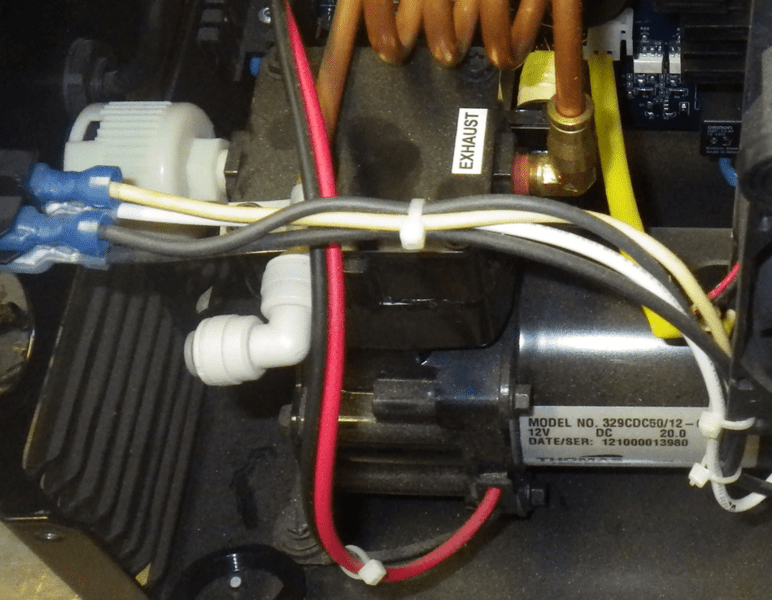

Internal filter clear and compressor both fine. That left the torch.

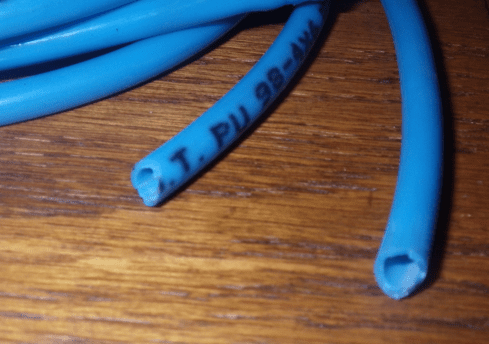

The tubing came out in two parts. One from each end a as it was broke about 4' out from the machine. Another split is further in..........

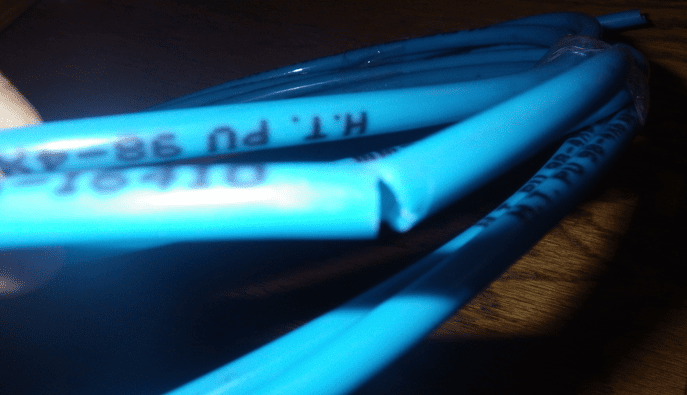

I don't know this tubing is anything "special" for the application. Looks to be just 16 ' of 4 mm X 6 mm polyurethane to me. Kind of surprised on the stiffness of it.

Any recommendations for replacement tube before I order something out of Amazon?

BTW, for the Miller owners........

Is this board branded with their logo??

..........................

I bought my Hobart 250 ci with internal compressor maybe 8 years ago. Worked fine up till a couple days ago.

Finished a cut, tried to start another, no air.

Internal filter clear and compressor both fine. That left the torch.

The tubing came out in two parts. One from each end a as it was broke about 4' out from the machine. Another split is further in..........

I don't know this tubing is anything "special" for the application. Looks to be just 16 ' of 4 mm X 6 mm polyurethane to me. Kind of surprised on the stiffness of it.

Any recommendations for replacement tube before I order something out of Amazon?

BTW, for the Miller owners........

Is this board branded with their logo??

..........................