Earlie A

Well-Known Member

You have to be part nerd to enjoy this stuff, so if you ain't nerdy you should probably close this post. Most of the lessons I learned here were 'duh' moments, but 'duh' moments with data seem to make sense to me.

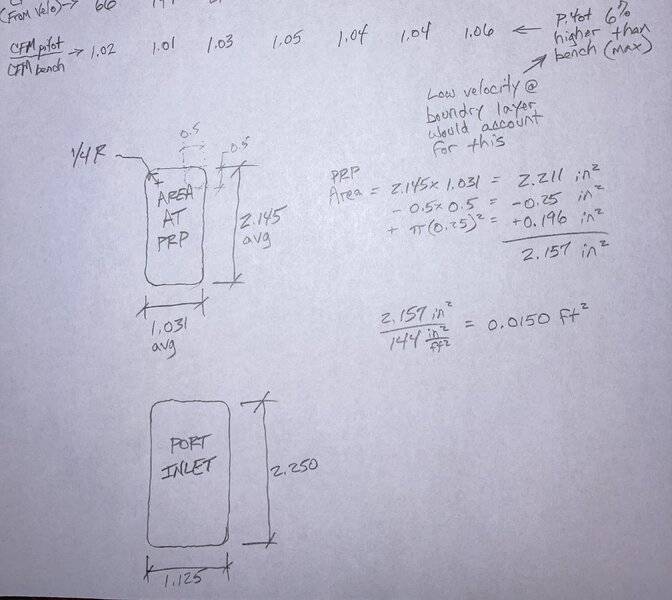

Anyway, this all started with wondering about the calibration of my pitot tube. Can I trust the velocity numbers that I am seeing? To verify, I took velocity measurements through a known area - the push rod pinch. Since the flow bench gives the cfm at the same time as velocity, the calculation (and verification) should be easy. Avg velocity(in feet per second) x area(in square feet) x 60(seconds per minute) = flow(in cfm).

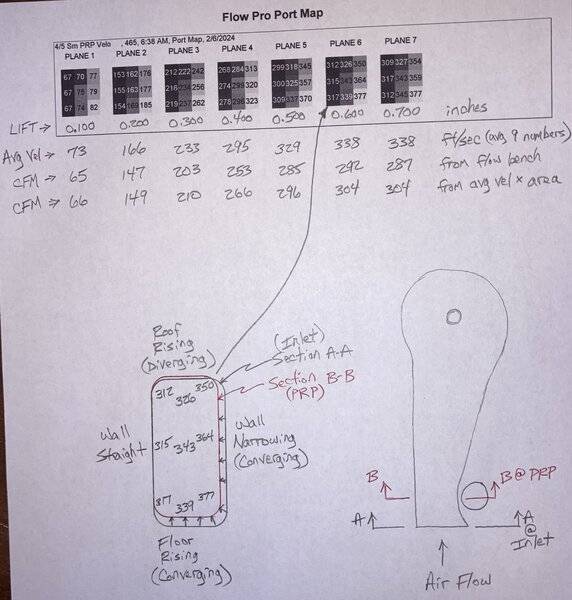

The test results can be seen in the pictures below. I measured velocity at seven different valve lift points, with nine velocity measurements taken at each lift. These velocities appear in the shaded boxes across the top of the page. The velocities are in specific zones or regions of the port. The first row of hand written numbers is the lift points. The second row of numbers is the average velocity at each lift, which is just the sum of all 9 numbers in the box divided by nine. The third row is the cfm flow rate given by the flow bench at each lift point. The fourth row is the cfm flow rate calculated from the equation listed above. Ideally, these two cfm numbers should match exactly. They do not, but why? Also, why are the velocity numbers all over the place?

Here's my learnings or 'duh' moments:

1. Chad Speier once said that the only velocity you need to measure is in the center of the port. He was somewhat joking, but compare the number in the center of each box to the calculated average velocity beneath it. Pretty close. That's 'duh' number one and it's perfectly logical.

2. Why are velocities much higher in one corner (bottom right) and much lower in the upper left? Velocities were taken at the push rod pinch, represented by section B-B in red in the drawing. The port inlet is section A-A. When the sections are superimposed, it can be seen that the floor of the port is rising, the right wall of the port is narrowing, and the roof is rising slightly. This means the area in the lower right is getting increasingly smaller (converging) and the area in the upper left is getting slightly larger. In the lower right, there is more air fighting for the same space, so it has to speed up. Thus the high velocity. Velocities are highest along the converging walls and lowest along the diverging wall. Another 'duh' moment for me. These things are really pretty simple, but for some reason not intuitive. These principles can also apply deeper into the port where things are more complicated and more important.

3. This one is a little more speculative and not really a 'duh'. Why do the cfm numbers not match exactly? In reality, there's pretty good correlation, especially at lower lifts/lower flows. At 100 and 200 lift, the numbers are within 1-2%. As lift increases and flow increases, the cfm calculated from the pitot velocity is 4-6% higher than the flow bench cfm, and the error increases as flow increases. That's still pretty good correlation, but here's what could be happening - and I would love to be corrected if wrong. I've read that flow in a port is not laminar, it is transitional or turbulent. So, the boundary layer (layer of no flow or low flow) along the walls increases in thickness as flow increases. This boundary layer growth cuts down the effective flow area. To get the same cfm through a smaller area, the velocity must increase. The equation above uses the same area for all calculations. At high flows, the area used in the calculations might be too high, making the calculated cfm number too high. Interesting to think about, at least to me. All of these lessons are data points in the ultimate goal of trying to understand converging/diverging and flow separation/turbulence that occur at various locations in the ports.

There could be all kinds of errors in this test. Flow bench could be off a little. Pitot tube could be off a little. My area measurements could be off a little. But my initial goal was to check the relative accuracy of my pitot tube. I think I learned a few other things along the way.

One last point I would like to make. I often hear the phrase "The flow bench will lie to you". Total hogwash. The flow bench gives pressures and velocities (which are based on pressures). That's it. It does not predict horsepower or ET's. The interpretation or use of the data may be wrong and lead to the 'lies', but a properly calibrated flow bench does not lie. It only gives raw data about dry air flow.

Sorry to get so long and rambling.

Anyway, this all started with wondering about the calibration of my pitot tube. Can I trust the velocity numbers that I am seeing? To verify, I took velocity measurements through a known area - the push rod pinch. Since the flow bench gives the cfm at the same time as velocity, the calculation (and verification) should be easy. Avg velocity(in feet per second) x area(in square feet) x 60(seconds per minute) = flow(in cfm).

The test results can be seen in the pictures below. I measured velocity at seven different valve lift points, with nine velocity measurements taken at each lift. These velocities appear in the shaded boxes across the top of the page. The velocities are in specific zones or regions of the port. The first row of hand written numbers is the lift points. The second row of numbers is the average velocity at each lift, which is just the sum of all 9 numbers in the box divided by nine. The third row is the cfm flow rate given by the flow bench at each lift point. The fourth row is the cfm flow rate calculated from the equation listed above. Ideally, these two cfm numbers should match exactly. They do not, but why? Also, why are the velocity numbers all over the place?

Here's my learnings or 'duh' moments:

1. Chad Speier once said that the only velocity you need to measure is in the center of the port. He was somewhat joking, but compare the number in the center of each box to the calculated average velocity beneath it. Pretty close. That's 'duh' number one and it's perfectly logical.

2. Why are velocities much higher in one corner (bottom right) and much lower in the upper left? Velocities were taken at the push rod pinch, represented by section B-B in red in the drawing. The port inlet is section A-A. When the sections are superimposed, it can be seen that the floor of the port is rising, the right wall of the port is narrowing, and the roof is rising slightly. This means the area in the lower right is getting increasingly smaller (converging) and the area in the upper left is getting slightly larger. In the lower right, there is more air fighting for the same space, so it has to speed up. Thus the high velocity. Velocities are highest along the converging walls and lowest along the diverging wall. Another 'duh' moment for me. These things are really pretty simple, but for some reason not intuitive. These principles can also apply deeper into the port where things are more complicated and more important.

3. This one is a little more speculative and not really a 'duh'. Why do the cfm numbers not match exactly? In reality, there's pretty good correlation, especially at lower lifts/lower flows. At 100 and 200 lift, the numbers are within 1-2%. As lift increases and flow increases, the cfm calculated from the pitot velocity is 4-6% higher than the flow bench cfm, and the error increases as flow increases. That's still pretty good correlation, but here's what could be happening - and I would love to be corrected if wrong. I've read that flow in a port is not laminar, it is transitional or turbulent. So, the boundary layer (layer of no flow or low flow) along the walls increases in thickness as flow increases. This boundary layer growth cuts down the effective flow area. To get the same cfm through a smaller area, the velocity must increase. The equation above uses the same area for all calculations. At high flows, the area used in the calculations might be too high, making the calculated cfm number too high. Interesting to think about, at least to me. All of these lessons are data points in the ultimate goal of trying to understand converging/diverging and flow separation/turbulence that occur at various locations in the ports.

There could be all kinds of errors in this test. Flow bench could be off a little. Pitot tube could be off a little. My area measurements could be off a little. But my initial goal was to check the relative accuracy of my pitot tube. I think I learned a few other things along the way.

One last point I would like to make. I often hear the phrase "The flow bench will lie to you". Total hogwash. The flow bench gives pressures and velocities (which are based on pressures). That's it. It does not predict horsepower or ET's. The interpretation or use of the data may be wrong and lead to the 'lies', but a properly calibrated flow bench does not lie. It only gives raw data about dry air flow.

Sorry to get so long and rambling.

Last edited: