I know it's been discussed before but looking for first hand experience. Car has 11 to 1 416. Currently has aluminum 22wide large 2row. With no Trans ports. Temp hits 160 almost as soon as get backed out of garage and hit pavement.160stat. Yesterday was 84 here went for about 30 min ride temp rose steadily to about 195. Acted like the more I drove the warmer it got. Trans also climbed to almost 220 only hooked through a cheap aluminum tube cooler. Has homebuilt shroud and 18" flex fan. Looking to replace with 22 or 26 3 or 4row with duall electric fans, and Trans ports. Bottom of rad support has allready been cut. What are you guys using? Anyone using the champion mc374 w duall 12" fans?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Radiator suggestions

- Thread starter MoparDave

- Start date

-

Post some photos of what you have now.

Rat Bastid

Dunamis Metron

More cores are not better.

I have to disagree here.More cores are not better.

The only way heat is transfered from the coolant to the air is through the fins.

The only way the heat is transfered from the coolant to the fins is through the tubes

The only way heat is transfered from the coolant to the tubes is by contact to the wall of the tubes.

The more surface area of the tubes the more heat that can be transfered.

The more contact points / surface area between the fins and the tubes the more heat can be transfered.

So if a 1 row core can transfer 100 btu in a set time then 2 cores can do about double, 3 cores can do about triple.

The reason I say about is there will be warmer air hitting the middle or last row of fins / tubes making them a little less efficient but they will still be effective.

Also...

If you go from 10 fins per inch to 20 fins per inch you will have about twice as much heat that can be transfered.

Of course there is a point of deminishing return where the fins per inch start to block airflow but that is no where near where radiators are.

65TerrorCuda

Well-Known Member

If the MP viscous fan fits, it's excellent. What happens temp wise at sustained freeway speeds?

Rat Bastid

Dunamis Metron

I have to disagree here.

The only way heat is transfered from the coolant to the air is through the fins.

The only way the heat is transfered from the coolant to the fins is through the tubes

The only way heat is transfered from the coolant to the tubes is by contact to the wall of the tubes.

The more surface area of the tubes the more heat that can be transfered.

The more contact points / surface area between the fins and the tubes the more heat can be transfered.

So if a 1 row core can transfer 100 btu in a set time then 2 cores can do about double, 3 cores can do about triple.

The reason I say about is there will be warmer air hitting the middle or last row of fins / tubes making them a little less efficient but they will still be effective.

Also...

If you go from 10 fins per inch to 20 fins per inch you will have about twice as much heat that can be transfered.

Of course there is a point of deminishing return where the fins per inch start to block airflow but that is no where near where radiators are.

It’s about coolant flow. Three .750 cores will not flow as much as 2 two 1 inch cores.

Simple as that. Coolant flow is more important than fin count or almost anything else.

Again I have to disagree, I could have all the coolant flow in the world but no fins (as in only the surface area of the tubes to transfer heat) and I'm not going to transfer much heat from the coolant to the air.Simple as that. Coolant flow is more important than fin count or almost anything else

Air cooled engines have no coolant flow (no coolant) but they have a huge surface area due to the fins on the cyl walls and head.

Not one single thing is more important in radiator design. It is a package and a dance between (no particular order) coolant flow, contact area, fin count, material, tube size and count, etc.

Still waiting on the OP to post up some photos of his current setup.

mderoy340

Well-Known Member

When my old factory 3 core 22" started leaking I upgraded my cooling on my 10.5:1 340/A999 4.30 gear car. 3200rpm at highway cruise in Florida.

6 vane OEM pump with 1970 340 single groove pulley.

180* low speed fan switch, 210* high speed.

No thermostat or restrictor washer, thermal switches control engine temp.

Trans cooler is external in front of radiator. Trans cooler in radiator not used.

This setup runs 180-185 traffic and cruise engine temp, 150 trans temp.

I made my own fan controller using 3 relays.

FORD CONTOUR Fans, Electric - Dual Fan Quantity - V6 Engine Type - Free Shipping on Orders Over $99 at Summit Racing

https://www.amazon.com/dp/B08C7C43QS/?tag=fabo03-20

https://www.amazon.com/dp/B0057H1WIA/?tag=fabo03-20

https://www.amazon.com/dp/B000C3BBKS/?tag=fabo03-20

6 vane OEM pump with 1970 340 single groove pulley.

180* low speed fan switch, 210* high speed.

No thermostat or restrictor washer, thermal switches control engine temp.

Trans cooler is external in front of radiator. Trans cooler in radiator not used.

This setup runs 180-185 traffic and cruise engine temp, 150 trans temp.

I made my own fan controller using 3 relays.

FORD CONTOUR Fans, Electric - Dual Fan Quantity - V6 Engine Type - Free Shipping on Orders Over $99 at Summit Racing

https://www.amazon.com/dp/B08C7C43QS/?tag=fabo03-20

https://www.amazon.com/dp/B0057H1WIA/?tag=fabo03-20

https://www.amazon.com/dp/B000C3BBKS/?tag=fabo03-20

Attachments

TheGrateRonzini

Well-Known Member

I got a 22” copper and brass recored with 4 row high efficiency core. It keeps my 440 quench motor with trick flow 240’s cool all summer. Has a single electric fan from a chevy hhr. Cost about 500

So when you are running down the highway you have nothing to control the temperature to keep it above a set minimum?No thermostat or restrictor washer, thermal switches control engine temp

mderoy340

Well-Known Member

Runs 180* on the highway (fans off) except for the one or two days a year it might get cold here in Florida. If I lived up north a thermostat would be ideal to control minimum temp.So when you are running down the highway you have nothing to control the temperature to keep it above a set minimum?

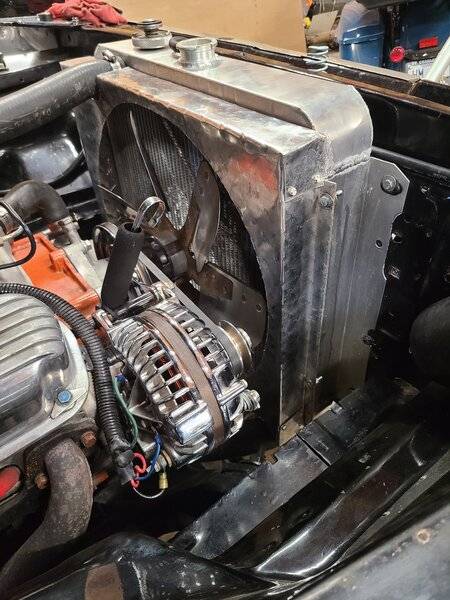

Allright sorry guys been busy, here's couple photos. Car had no shroud, when I bought it, I threw that together to see if it would help . It did minimally. Went ahead and ordered the 26" 4row. I'm about 25-30 minutes from anywhere, would like the ability to cruise to a cruise night and play a bit, in the heat. Also want to run Trans through the rad and through a plate cooler. May be overkill idk,we'll see. As far as the 2 vs 4 debate, I like to look at core thickness. Most 2 row are 1.5 . This 4row is 2.75 thick. That has to be more coolant flow and more heat transfer?

IMHO you have some other issue going on. You currently have plenty of fan and radiator.. I'm about 25-30 minutes from anywhere, would like the ability to cruise to a cruise night and play a bit, in the heat

ARE YOU SURE your temperature reading is correct?

I'm not a fan of shrouds that are parallel to the radiator core ( I don't want to get into it, again) but yours is very far away from the rad so you should not have any issues.

IMHO if the factory could cool a 383 or 440 in a dart with a 22" 2 core ( might have been 3 core???) radiator than you should be able to also.

You either have a bad water pump, bad thermostat, or your pulley ratio is way out of wack.

Or you have blocked passages, clogged radiator, head gasket leak, or some other mechanical issue.

What is the diameter of your wp pulley?

What is the diameter of your crank pulley?

mcodecuda

Senior Member

The factory stuff works the best. I would dump that flex fan and used a 3 core 22” factory radiator. Hell I ran a 22” 318 A/C radiator in my 440 cuda and it never ran over 195 ever.Allright sorry guys been busy, here's couple photos. Car had no shroud, when I bought it, I threw that together to see if it would help . It did minimally. Went ahead and ordered the 26" 4row. I'm about 25-30 minutes from anywhere, would like the ability to cruise to a cruise night and play a bit, in the heat. Also want to run Trans through the rad and through a plate cooler. May be overkill idk,we'll see. As far as the 2 vs 4 debate, I like to look at core thickness. Most 2 row are 1.5 . This 4row is 2.75 thick. That has to be more coolant flow and more heat transfer?View attachment 1715917080 View attachment 1715917081

Not trying to sidetrack this, but I think this is a relevant argument. Tell me using @Rat Bastid's example you disagreed with, how three rows of .75 tubes can out cool two rows of 1" tubes. That's a full 1/2" more of tubes (2") versus 1.5". Also of note is, he used that as but an example. Most two row aluminum radiators (the good ones anyway) use either 1.25" or 1.5" tubes, so that's even more cooling ability.Again I have to disagree, I could have all the coolant flow in the world but no fins (as in only the surface area of the tubes to transfer heat) and I'm not going to transfer much heat from the coolant to the air.

Air cooled engines have no coolant flow (no coolant) but they have a huge surface area due to the fins on the cyl walls and head.

Not one single thing is more important in radiator design. It is a package and a dance between (no particular order) coolant flow, contact area, fin count, material, tube size and count, etc.

Still waiting on the OP to post up some photos of his current setup.

Regardless, he is correct about coolant flow, as that's what's important. Getting the coolant out of the engine as quickly as possible so it does not heat up. I have proven him correct in that through my own experiences first hand.

If the radiator is up to task, and I see no reason why it wouldn't be, then he should be looking at coolant flow. IMO, he should optimize that first as for one, it will be much, much more cost effective and two, a new radiator may not solve his issue.

@MoparDave, have you put an infra red temp gun on the radiator inlet and then the outlet to see the temperature drop of the coolant from coming into the radiator to going out? That right there will tell you how good the radiator is working. A new 160 high flow thermostat is way cheaper than a new radiator if you don't have that already. That does two things. First, it opens sooner which allows the coolant to get out before the engine gets any hotter. Secondly the high flow feature allows more of the coolant to leave the engine more quickly than a standard flow. And I don't mean one of those junky Mr. Gasket thermostats, either. You need a Stewart Components 160 high flow thermostat. They are the best you can get. I would try that well before I thought about another radiator. Only after I did those things and the radiator was still not doing the job would I replace it. I think doing it beforehand is premature. All this of course is one peon's opinion, but it's based in the reality of me solving my problem just as I outlined here. Good luck!

As far as the 2 vs 4 debate, I like to look at core thickness. Most 2 row are 1.5 . This 4row is 2.75 thick. That has to be more coolant flow and more heat transfer?

Lets get this out of the way. The radiator hasn't a thing to do with flow. Nothing. Nada. Zilch. Well......unless it's stopped up. lol

FLOW comes from the water pump and the flow size of the thermostat. Period. In fact, the more rows a radiator has, the more of a restriction it becomes. This is why a WELL DESIGNED two row radiator with either 1.25" or 1.50" tubes will outflow and out cool most three and four row radiators. That's why everybody's goin to um. They work!

My example I spoke of above is somewhat similar to yours, although my car has a slant six. I measured 10.2:1 when I assembled it, but I think I goofed somewhere because even with a large flat tappet (250 duration @.050") it STILL has over 175 PSI cranking pressure. It HAD a detonation issue when I first got it running. I did several thing one step at a time. Colder plugs, blocked off the exhaust to intake heat, tightened up the valve lash. EACH thing I did helped a little but didn't cure it. The one thing that did was when I put in the 160 high flow thermostat. I don't even have a temperature gauge....well.....it has the factory gauge and it works. It was running right at and a tick past half way before the change. Now it runs 1/4 of the way at the very most. Still has the slant six four blade useless fan. I think I could throw it in the ditch and it still wouldn't run hot at this point. That's what mine needed. FLOW. Once I gave it that, no more spark knock and it runs MUCH cooler and better. He's not pullin your leg. If you don't have a high flow thermostat, get one. A 160. I bet it might work.

3 rows of .75” tubes is = to 2.25”.Not trying to sidetrack this, but I think this is a relevant argument. Tell me using @Rat Bastid's example you disagreed with, how three rows of .75 tubes can out cool two rows of 1" tubes. That's a full 1/2" more of tubes (2") versus 1.5". Also of note is, he used that as but an example. Most two row aluminum radiators (the good ones anyway) use either 1.25" or 1.5" tubes, so that's even more cooling ability.

2 rows of 1” tubes is = to 2”.

Where did you get 1.5” tubes?

My bad. I haven't slept all night. Forgive me. I stand by most of the rest of it though.3 rows of .75” tubes is = to 2.25”.

2 rows of 1” tubes is = to 2”.

Where did you get 1.5” tubes?

IMHO you have some other issue going on. You currently have plenty of fan and radiator.

ARE YOU SURE your temperature reading is correct?

The guage is a mechanical autometer. Seems to operate fine, although it could be off. Thermostat is a 160 Mr gasket high flow. Pulleys are 6.5. This 2 row in it has maybe 5/8 to 3/4 tubes.Everything on the car is fairly new no clogs etc. And at 55-60mph I'm at 2800ish rpm so it should be flowing, as its above 160, and I pulled and tested stat.And while it could maybe be optimized to work , I want the Trans lines going through it to stabilize the Trans temp. The 4row will be here tomorrow, I'll install obviously no shroud, but same everything else and we'll see if helps

I'm not a fan of shrouds that are parallel to the radiator core ( I don't want to get into it, again) but yours is very far away from the rad so you should not have any issues.

IMHO if the factory could cool a 383 or 440 in a dart with a 22" 2 core ( might have been 3 core???) radiator than you should be able to also.

You either have a bad water pump, bad thermostat, or your pulley ratio is way out of wack.

Or you have blocked passages, clogged radiator, head gasket leak, or some other mechanical issue.

What is the diameter of your wp pulley?

What is the diameter of your crank pulley?

IMHO you have some other issue going on. You currently have plenty of fan and radiator.

ARE YOU SURE your temperature reading is correct?

I'm not a fan of shrouds that are parallel to the radiator core ( I don't want to get into it, again) but yours is very far away from the rad so you should not have any issues.

IMHO if the factory could cool a 383 or 440 in a dart with a 22" 2 core ( might have been 3 core???) radiator than you should be able to also.

You either have a bad water pump, bad thermostat, or your pulley ratio is way out of wack.

Or you have blocked passages, clogged radiator, head gasket leak, or some other mechanical issue.

What is the diameter of your wp pulley?

What is the diameter of your crank pulley?

Idk what happened to reply but here goes again.

Everything on the car is fairly new, it has a high flow 160 Stat, fine I tested it. When I'm driving 55 -60mph it is 2800ish rpm so has to be flowing. The 2row in it is maybe 5/8 tubes. The pulleys are both 6.5". The 4row will be here tomorrow so I'll swap and report back. Also I wanted the Trans lines in rad to stabilize the Trans temp,it has a 4000 I think 8-9" converter it's allready smoked 1 Trans prob from overheating.

Everything on the car is fairly new, it has a high flow 160 Stat, fine I tested it. When I'm driving 55 -60mph it is 2800ish rpm so has to be flowing. The 2row in it is maybe 5/8 tubes. The pulleys are both 6.5". The 4row will be here tomorrow so I'll swap and report back. Also I wanted the Trans lines in rad to stabilize the Trans temp,it has a 4000 I think 8-9" converter it's allready smoked 1 Trans prob from overheating.

Sounds like there's more at play here than "just" engine heat.Idk what happened to reply but here goes again.

Everything on the car is fairly new, it has a high flow 160 Stat, fine I tested it. When I'm driving 55 -60mph it is 2800ish rpm so has to be flowing. The 2row in it is maybe 5/8 tubes. The pulleys are both 6.5". The 4row will be here tomorrow so I'll swap and report back. Also I wanted the Trans lines in rad to stabilize the Trans temp,it has a 4000 I think 8-9" converter it's allready smoked 1 Trans prob from overheating.

The factory stuff works the best. I would dump that flex fan and used a 3 core 22” factory radiator. Hell I ran a 22” 318 A/C radiator in my 440 cuda and it never ran over 195 ever.

I know the fan I have isn't the best but hoping with larger rad I can run the duall electric setup, after watching Freiburger test fans not wanting to give up the almost 30hp it takes to run the mopar

No worries, I wasn’t sure what I was looking at.My bad. I haven't slept all night. Forgive me. I stand by most of the rest of it though.

Is your fan about half way out of the shroud? If it is all the way in the shroud, it will overheat at idle & nothing you do will help. Don’t ask how I know……

Evidently, neither was I. LOLNo worries, I wasn’t sure what I was looking at.

-