j par

Well-hung Member

I know many of you are like me it's just a hobby and can't afford to buy expensive tools to do a job one time. Also llike myself have to make/ modify some tool?

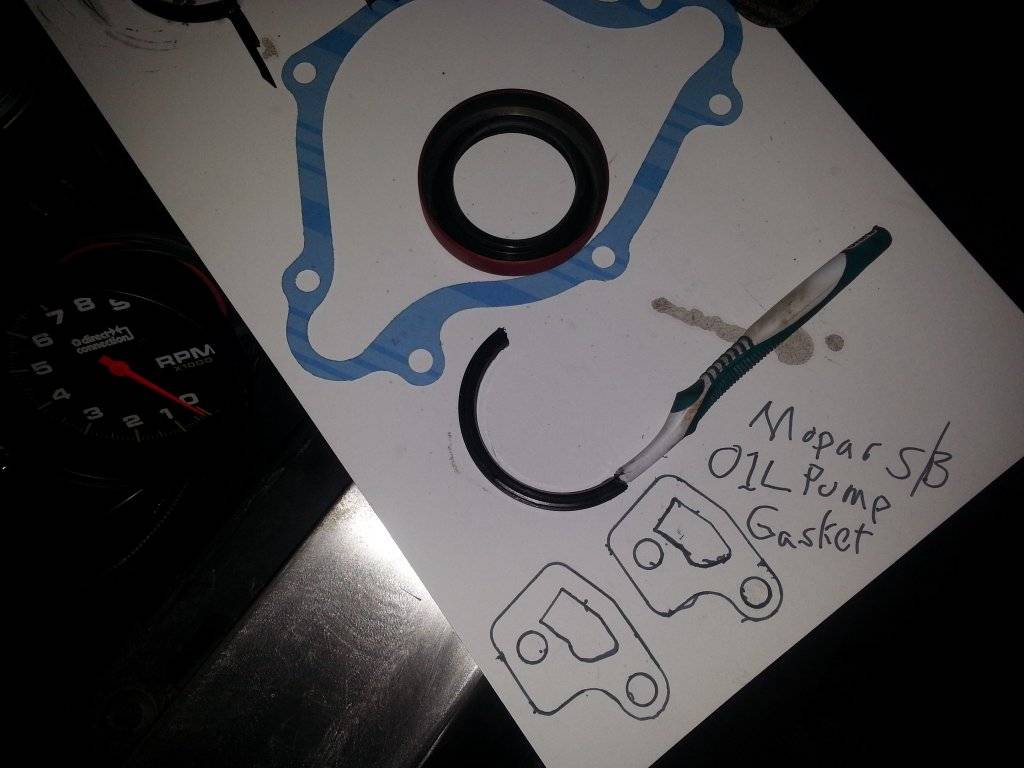

Was told to use something wood or plastic to push out my rear main seal and as I'm looking around the garage for something I can use- wife says how about a toothbrush modify? I say good idea and go the drawer where I keep all toothbrushes in the garage as cleaners. The head of the brush just snapped off in my hand and took it to the grinder just to dress it up and crush the backside of it in to. the grinder to make a flat spot for hammering. It worked perfect! Will be the redneck tool of the week for me....

Was told to use something wood or plastic to push out my rear main seal and as I'm looking around the garage for something I can use- wife says how about a toothbrush modify? I say good idea and go the drawer where I keep all toothbrushes in the garage as cleaners. The head of the brush just snapped off in my hand and took it to the grinder just to dress it up and crush the backside of it in to. the grinder to make a flat spot for hammering. It worked perfect! Will be the redneck tool of the week for me....

So I'm not the only one that made gaskets out of poster board?

So I'm not the only one that made gaskets out of poster board?