74desertduster

Well-Known Member

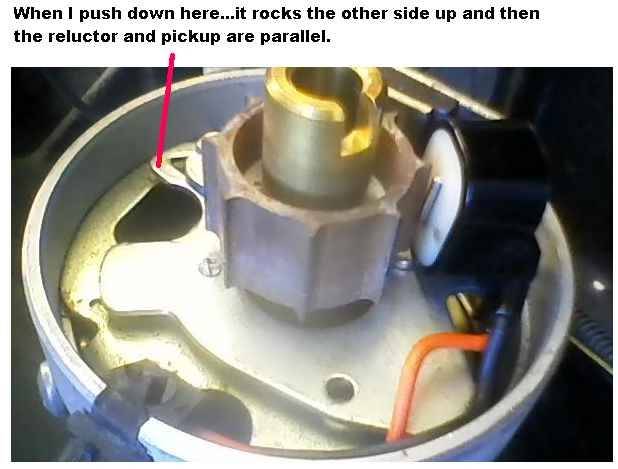

So I was checking my rotor and such today and discovered that my Reluctor and the Pickup Coil are not parallel where they should be gapped.

The plate that the pickup sits on is pivoting from side to side when I press down on it. It acts like it is pivoting on a locating pin or screw or something.

I can't figure out what holds the plate with pickup on the disty so have not been able to take it apart and see if something got under it or what?

Haven't had a Mopar in 25 years so all is new again.

Any thoughts?

Thanks for all the help on FABO!

Brian

The plate that the pickup sits on is pivoting from side to side when I press down on it. It acts like it is pivoting on a locating pin or screw or something.

I can't figure out what holds the plate with pickup on the disty so have not been able to take it apart and see if something got under it or what?

Haven't had a Mopar in 25 years so all is new again.

Any thoughts?

Thanks for all the help on FABO!

Brian