I'm asking for a friend. He's building a small block Mopar 360 with a hydraulic cam and adjustable roller rockers. He wants to know after you adjust all of your rockers should there be any play side to side in any of the push rods?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rocker adjustment

- Thread starter texas360

- Start date

-

MOPAROFFICIAL

Oogliboogli

They 'the rockers' will move side to side, they should have about .015 side clearance.

Hyd lifter adj, Adjust the rockers till the lifters dont tick anymore.

Hyd lifter adj, Adjust the rockers till the lifters dont tick anymore.

dano

Evil Handy Man

No not the push rods. The rockers can slide side to side some when on the base circle.

pishta

I know I'm right....

Adjust until your pushrods hang on the lifters when you try and turn them, then another 1/2 turn on the base circle for preload on a hydro

Thanks guys. I'll let him know. I haven't got mine complete yet. I'm running bigger springs so I have to clearance rockers. I'm running 273 rockers with banjo shafts. He running pro comp aluminum rockers.

yellow rose

Overnight Sensation

Thanks guys. I'll let him know. I haven't got mine complete yet. I'm running bigger springs so I have to clearance rockers. I'm running 273 rockers with banjo shafts. He running pro comp aluminum rockers.

If you have to grid on the rocker you need to stop and fix the geometry. Here is no reason to grind a rocker. The geometry is wrong or they wouldn’t hit the spring, unless it’s 1.625 diameter, which I know it’s not.

It's a casting flaw. Even in the book How to Hot Rod your small block mopar they show where you clearance 273 rockers for bigger springs.If you have to grid on the rocker you need to stop and fix the geometry. Here is no reason to grind a rocker. The geometry is wrong or they wouldn’t hit the spring, unless it’s 1.625 diameter, which I know it’s not.

pishta

I know I'm right....

From published sources....

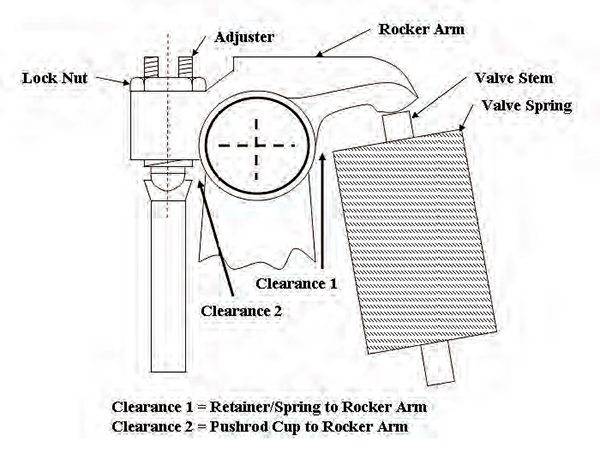

The rocker arm in mechanical valvetrain systems often has clearance issues with the valvespring and retainer and also with the pushrod cup. Most mechanical rocker arms have a relief under the arm near the valve tip for retainer clearance and a relief on the underside of the pushrod arm to clear the cup-end. As the cam lifts get higher, the outside diameter of the valvesprings increases. These issues must be addressed.

The rocker arm in mechanical valvetrain systems often has clearance issues with the valvespring and retainer and also with the pushrod cup. Most mechanical rocker arms have a relief under the arm near the valve tip for retainer clearance and a relief on the underside of the pushrod arm to clear the cup-end. As the cam lifts get higher, the outside diameter of the valvesprings increases. These issues must be addressed.

yellow rose

Overnight Sensation

It's a casting flaw. Even in the book How to Hot Rod your small block mopar they show where you clearance 273 rockers for bigger springs.

The book is wrong. How big are the springs? 1.550? Even those don’t need a notch IF the geometry is correct.

yellow rose

Overnight Sensation

From published sources....

View attachment 1715646664

The rocker arm in mechanical valvetrain systems often has clearance issues with the valvespring and retainer and also with the pushrod cup. Most mechanical rocker arms have a relief under the arm near the valve tip for retainer clearance and a relief on the underside of the pushrod arm to clear the cup-end. As the cam lifts get higher, the outside diameter of the valvesprings increases. These issues must be addressed.

See post 9.

I seen post 9. That was where i had to clearance my rockers. Not all of them, just a few that had some extra casting. My valve train geometry is fine.See post 9.

yellow rose

Overnight Sensation

here is the rockers when i mocked them up before removing to clearance the underside,, there is no spring reliefs cut in these at allView attachment 1715646966 View attachment 1715646967 View attachment 1715646968 View attachment 1715646969 View attachment 1715646970 View attachment 1715646971 underneath

Exactly. Your geometry is WRONG. I can’t say it any nicer than that. You are arguing a point just to be right, and you’re not.

That head has a taller stem height than a 273 ever had. That changes geometry. Are you running .450ish lift? If not that changes geometry. The stands on that head haven’t been relocated for your stem height and lift. So your geometry is wrong.

I’m trying to help you and keep you from doing damage to a rocker that doesn’t need it. Almost never does a rocker need to be ground on. The book you are reading is wrong. Don’t grind them. Call Mike at B3 racing engines and talk to him.

It’s criminal how many rockers have been junked from grinding on them. It’s criminal that Chrysler guys put up with geometry issues where there is no need for it.

b3racingeninges.com has 4 tech articles on this very subject. Please take the time to go read through them and then call Mike and let him help you. Your rockers, valve train and engine will thank you for spending the time to fix your issue.

I can not say it any better than that. You have led yourself into a corner, it's going to cost you some time, a geometry kit, maybe a new set of pushrods and a phone call.

Just do it, you haven't hurt anything yet.

Just do it, you haven't hurt anything yet.

Exactly. Your geometry is WRONG. I can’t say it any nicer than that. You are arguing a point just to be right, and you’re not.

That head has a taller stem height than a 273 ever had. That changes geometry. Are you running .450ish lift? If not that changes geometry. The stands on that head haven’t been relocated for your stem height and lift. So your geometry is wrong.

I’m trying to help you and keep you from doing damage to a rocker that doesn’t need it. Almost never does a rocker need to be ground on. The book you are reading is wrong. Don’t grind them. Call Mike at B3 racing engines and talk to him.

It’s criminal how many rockers have been junked from grinding on them. It’s criminal that Chrysler guys put up with geometry issues where there is no need for it.

b3racingeninges.com has 4 tech articles on this very subject. Please take the time to go read through them and then call Mike and let him help you. Your rockers, valve train and engine will thank you for spending the time to fix your issue.

i am not trying to argue point. these are just things i have ready or been told.

im still learning this... would i be better to just run stock rockers? im running the Hughes Whiplash cam.. intake 0.480/ exhaust 0.516 with 1.5 rockers... im just going off what i have read in different books and online forums... lots of people i have found ran these rockers with aluminum heads and a 0.480 and bigger cam... i want it to be right.. im trying to just get it figured out... even when i put the stock stamped rockers on with no pushrods they are as close as these to the springs. other than shims how could i get the rockers farther from the springs? they fall where they fall becasue they are on a rocker shaft..

For some reason you seem to doubt what we are trying tell you. Could you please just call Mike at B3 Racing? He will answer your questions and get you on your way.

717 497 6572

Or you can believe what you have read.

717 497 6572

Or you can believe what you have read.

Phreakish

Well-Known Member

i am not trying to argue point. these are just things i have ready or been told.

im still learning this... would i be better to just run stock rockers? im running the Hughes Whiplash cam.. intake 0.480/ exhaust 0.516 with 1.5 rockers... im just going off what i have read in different books and online forums... lots of people i have found ran these rockers with aluminum heads and a 0.480 and bigger cam... i want it to be right.. im trying to just get it figured out... even when i put the stock stamped rockers on with no pushrods they are as close as these to the springs. other than shims how could i get the rockers farther from the springs? they fall where they fall becasue they are on a rocker shaft..

Some more reading that will make it obvious what YR and Cruze are talking about:

B3 Racing Engines LLC - Mopar Rocker Arm Geometry Tech

-