I see some questionable things here. Perhaps you already fixed them.

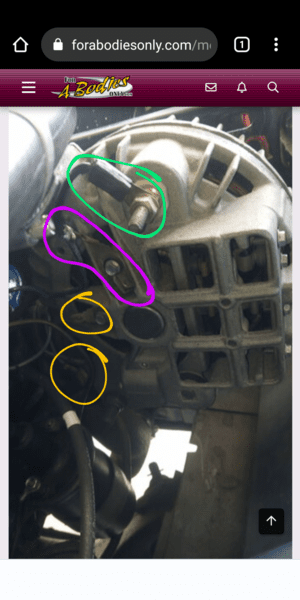

The lower yellow circle appears to be the green field wire disconnected.

The upper yellow circle appears to be the field post it might go on

The magenta circle looks to have a connector on it but soldered to the output charge wire

The green circle is the output charge wire from the alternator to the battery

Don't know what is going on there.

The typical square back uses 2 field wires, one is full battery voltage the other comes from the electronic voltage regulator

There are square back alternators that have been modified by grounding one terminal and work with the old electro mechanical regulators.

This is where what voltage regulator you have is super important.

The lower yellow circle appears to be the green field wire disconnected.

The upper yellow circle appears to be the field post it might go on

The magenta circle looks to have a connector on it but soldered to the output charge wire

The green circle is the output charge wire from the alternator to the battery

Don't know what is going on there.

The typical square back uses 2 field wires, one is full battery voltage the other comes from the electronic voltage regulator

There are square back alternators that have been modified by grounding one terminal and work with the old electro mechanical regulators.

This is where what voltage regulator you have is super important.