You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stagger jetting question

- Thread starter 66Valiant528

- Start date

-

Here it is. I hope it's visible. I also got what David Vizard wrote.

And yes, I have a spacer under my 950. Maybe they put it there to even out the fuel distribution as Indy headed smallblock pointed out. Maybe I shouldn't mess with it.

And yes, I have a spacer under my 950. Maybe they put it there to even out the fuel distribution as Indy headed smallblock pointed out. Maybe I shouldn't mess with it.

I was thinking about adding some jet as Visard suggests but not dropping the other 2 jets down in size. Just fatter in those 2 corners.

I think individual header readings could help.

I think individual header readings could help.

Rat Bastid

Dunamis Metron

Here it is. I hope it's visible. I also got what David Vizard wrote.

And yes, I have a spacer under my 950. Maybe they put it there to even out the fuel distribution as Indy headed smallblock pointed out. Maybe I shouldn't mess with it.

View attachment 1715802218

That’s what I was alluding to about the firing order. Unfortunately it is more complicated than that. It’s not just the firing order that causes distribution issues. If you have an overall rich condition, or if you have a manifold that isn’t conducive to keeping the fuel in the air and the fuel and air are separating when that fuel hits the floor or even the walls we don’t have any idea where it will go. I remember some stuff on the dyno at one time. The guy doing the port work went to great lengths to get the floor of the manifold into an inverted V shape. I think it was a Victor intake. It was on the dyno for several days and they had numbers for the intake before he did the floor modifications. Once he changed the floor the power dropped like a rock, the BSFC numbers went way up and the distribution was way worse and it didn’t make any sense. I’ll never forget that because the guy doing the work couldn’t understand why the distribution went out of control. In the end, he made the floor flat again and power came back and the BSFC numbers were back in line. The point is many things conspire together to affect or change distribution patterns. You have to be very careful modifying intakes and such because the results aren’t always intuitive.

j par

Well-Known Member

From my post number six I always wonder why someone disagrees and then doesn't give a reason why? Did this not happen to me yesterday, was I imagining it? LOL...Generally almost never does a carburetor jump out of a box and onto a car and run perfect...

But never say never LOL...

It actually happened to me yesterday for the first time in my life...

We broke in a mid-60s 327 for a customer's 65 Chevelle on an engine stand with a known carburetor. Yesterday we got it ready for a test drive and after setting the timing the dual AF gages were reading just about perfect... I checked this brand new 1406 carburetor that we pulled out of the box and it was out 3/4 of a turn on both adjustment screws. I had to turn the idle up... Afterwards I tried to make some adjustments but nothing made it run better so I left it where it was...

I really think that these kind of 350 327 Chevys were what these were built around anyway so I guess it is possible I just never seen it before.

That's great advice. I have no plans to modify my M1 Max Wedge 4150 intake.That’s what I was alluding to about the firing order. Unfortunately it is more complicated than that. It’s not just the firing order that causes distribution issues. If you have an overall rich condition, or if you have a manifold that isn’t conducive to keeping the fuel in the air and the fuel and air are separating when that fuel hits the floor or even the walls we don’t have any idea where it will go. I remember some stuff on the dyno at one time. The guy doing the port work went to great lengths to get the floor of the manifold into an inverted V shape. I think it was a Victor intake. It was on the dyno for several days and they had numbers for the intake before he did the floor modifications. Once he changed the floor the power dropped like a rock, the BSFC numbers went way up and the distribution was way worse and it didn’t make any sense. I’ll never forget that because the guy doing the work couldn’t understand why the distribution went out of control. In the end, he made the floor flat again and power came back and the BSFC numbers were back in line. The point is many things conspire together to affect or change distribution patterns. You have to be very careful modifying intakes and such because the results aren’t always intuitive.

33IMP

Well-Known Member

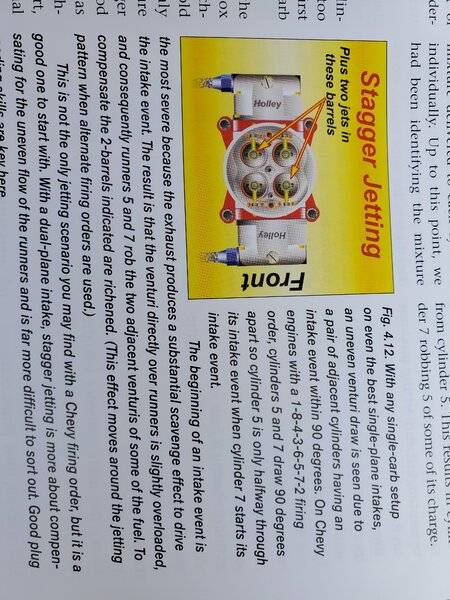

Vizard is English isn't he? His passenger side is the left side of the car.ok, but how do you tell #7 cylinder to pull from the 76 jet rear throttle plate on the drivers side and #5 cylinder to pull from the 78 jet rear throttle plate on the passenger side on an open plenum ?? I'm not being sarcastic at all, but I don't understand.

Either way, I don't get the concept. Not saying it doesn't work, just say'n I don't understand how a cylinder knows to pull from one throttle plate where the jetting is XX and not the other throttle plate which is XX jetting.... when all 4 throttle plates are exposed on an open plenum to every cylinder.Vizard is English isn't he? His passenger side is the left side of the car.

He is saying that 5 and 7 are adjoining and sequential cylinders. 18436572...

Cylinder 5 has momentum that interferes with the column of air that #5 is trying to get moving.

He puts a knife edge on the inside edge of #7 and rounds of the adjoing edge of #5 to encourage the start of flow into #7 and discourage scavenging from #5.

He also suggests drilling a series of divots using just the tip of a 5/16" bit around the ports to catch any pooling fuel droplets.

I hope I got that all correct....

I will find the videos and oost links.

Cylinder 5 has momentum that interferes with the column of air that #5 is trying to get moving.

He puts a knife edge on the inside edge of #7 and rounds of the adjoing edge of #5 to encourage the start of flow into #7 and discourage scavenging from #5.

He also suggests drilling a series of divots using just the tip of a 5/16" bit around the ports to catch any pooling fuel droplets.

I hope I got that all correct....

I will find the videos and oost links.

More Voodoo than science.

The original Carter 625/750 AVS carbs used on 383/440 engines. The holes in the secondary discharge tubes are hard to see because they are drilled from the rear of the tubes before the tubes are pressed in. If you remove the tubes from a 625 & 750, the hole placement & size is slightly different between L & R & between each carb size. I assume this was to try & get the A/F ratio as close as possible for each runner.

TQs are the same. Hole sizes, locations different.

The original Carter 625/750 AVS carbs used on 383/440 engines. The holes in the secondary discharge tubes are hard to see because they are drilled from the rear of the tubes before the tubes are pressed in. If you remove the tubes from a 625 & 750, the hole placement & size is slightly different between L & R & between each carb size. I assume this was to try & get the A/F ratio as close as possible for each runner.

TQs are the same. Hole sizes, locations different.

Puzackly. Trying to nail down your tuning on a specific engine per a book is kinda pointless, since they all act and want different things. Best to just let the engine tell you what it wants. If it responds to staggered jetting, then all the better. If not, leave it be.I staggered the primary jetting between my front and rear carburetors...

If you were to buy a dual quad Edelbrock carburetor set up they'd be jetted and set up different..

I would say carburetors are very motor specific.. and getting them right takes experimentation...

Yup and that's part of the reason for camshafts that have 5&7 swapped on the firing order. .....but I honestly think that while in some cases, it may benefit, I think for the most part, it's splittin hairs.He is saying that 5 and 7 are adjoining and sequential cylinders. 18436572...

Cylinder 5 has momentum that interferes with the column of air that #5 is trying to get moving.

He puts a knife edge on the inside edge of #7 and rounds of the adjoing edge of #5 to encourage the start of flow into #7 and discourage scavenging from #5.

He also suggests drilling a series of divots using just the tip of a 5/16" bit around the ports to catch any pooling fuel droplets.

I hope I got that all correct....

I will find the videos and oost links.

65 Val.

Since your computer skills are much better than mine, could you please post page 30 of DVs book. Top left of page. Bottom of page 38 is also important.

It has a very important message about idle ign timing & it will benefit FABO members.

Thanks.

Since your computer skills are much better than mine, could you please post page 30 of DVs book. Top left of page. Bottom of page 38 is also important.

It has a very important message about idle ign timing & it will benefit FABO members.

Thanks.

Yup and that's part of the reason for camshafts that have 5&7 swapped on the firing order. .....but I honestly think that while in some cases, it may benefit, I think for the most part, it's splittin hairs.

But that swap just moves the issue to #2/4 ports so I cant see how it fixes the problem . Visard said the swap helps minimize harmonic vibrations but he has seen no real proof of that .

I agree! But tell the Chevy boys that chit. They think the 5&7 swap unlocks another 100HP. And that ain't no joke. ....but then, most of them think addin chrome valve covers add 20HP too, so........But that swap just moves the issue to #2/4 ports so I cant see how it fixes the problem . Visard said the swap helps minimize harmonic vibrations but he has seen no real proof of that .

33IMP

Well-Known Member

Engine masters did a test of the firing order swap. It's been a while since I saw it, but if I remember correctly it made...... nothing. Maybe 5 hp.I agree! But tell the Chevy boys that chit. They think the 5&7 swap unlocks another 100HP. And that ain't no joke. ....but then, most of them think addin chrome valve covers add 20HP too, so........

Edit: watching the episode right now. Will report back.

Last edited:

33IMP

Well-Known Member

Okay! At peak, the 4/7 swap made .9hp, that's nine tenths of one horsepower, on an 800hp test engine. So that is just barely over one tenth of one percent. The average was up about 2.4 hp, so, .25%. Surely worth a custom $500 cam, and tearing down your engine for.

Well, maybe not.

Edit: the firing order change also changed cylinder to cylinder distribution......made it worse. One cylinder went way lean compared to standard.

Well, maybe not.

Edit: the firing order change also changed cylinder to cylinder distribution......made it worse. One cylinder went way lean compared to standard.

Talk about splittin hairs!Okay! At peak, the 4/7 swap made .9hp, that's nine tenths of one horsepower, on an 800hp test engine. So that is just barely over one tenth of one percent. The average was up about 2.4 hp, so, .25%. Surely worth a custom $500 cam, and tearing down your engine for.

Well, maybe not.

Edit: the firing order change also changed cylinder to cylinder distribution......made it worse. One cylinder went way lean compared to standard.

B3422w5

Well-Known Member

Okay! At peak, the 4/7 swap made .9hp, that's nine tenths of one horsepower, on an 800hp test engine. So that is just barely over one tenth of one percent. The average was up about 2.4 hp, so, .25%. Surely worth a custom $500 cam, and tearing down your engine for.

Well, maybe not.

Edit: the firing order change also changed cylinder to cylinder distribution......made it worse. One cylinder went way lean compared to standard.

driver of a car taking a healthy dose of prune juice before hopping behind the wheel would likely net just as much effect…if you hit the can first

Top left of page 30 bottom of page 38

The 5/7 swap. My understanding is that it evens out the firing pulses that the crank sees. Since the crank is connected to the cam, the cam & valve train get a smoother ride which can add a small amount of power.

Mattax

Just the facts, ma'am

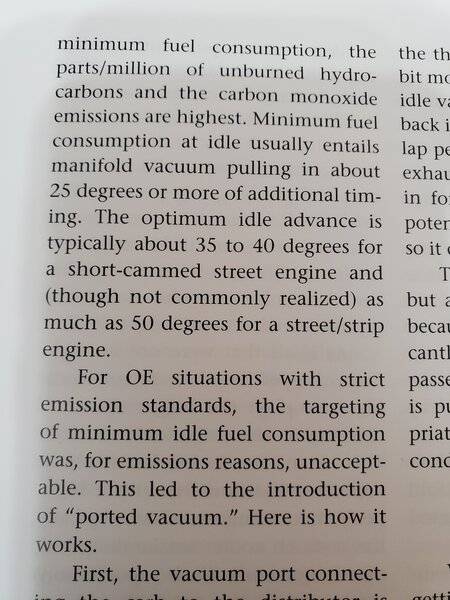

Note the recommended idle timing. It will come as a shock to some.....

Vizard is a good writer. However I learned the hard way to be very very careful in assessing whether specific modifications can be applied from his tests or experience to whatever it is I'm working on. All too often generalizations fail when based on too small of a data pool. He is also limited to the format of the SA publications so stuff gets left out.

Differences in exhaust arrangements, stroke/rod, valve timing, etc can effect the intake and fuel distribution.

So let's get back to my original question. Does anyone do the staggered jetting? I am not going to mod the intake and my engine was a little lean on the dyno. The builder jetted up, but my final pulls were set at 13.2 to 1. I was only considering adding a jet size or 2 up . I understand why Vizard wants the two opposite corners done. My intake is an unmodified open plenum max wedge port M1. There is a 1 inch spacer installed by the builder.

I appreciate the answers and my dizzy is locked at 36. This is race only. I know every combo is different and may respond differently. So let's keep it simple. Anybody running staggered jetting on an open plenum intake?

And thank you all. I wish my thread on leaning out my cruise A/F ratio on my street dual quad tunnel ram Roadrunner got as many replies! That has been a mess. Clearly running on the transition slot and rich. The people at Holley can only offer to sell me new Quick fuel 450s or there new FI tunnel ram set up.....oh well. Thanks again all.

I appreciate the answers and my dizzy is locked at 36. This is race only. I know every combo is different and may respond differently. So let's keep it simple. Anybody running staggered jetting on an open plenum intake?

And thank you all. I wish my thread on leaning out my cruise A/F ratio on my street dual quad tunnel ram Roadrunner got as many replies! That has been a mess. Clearly running on the transition slot and rich. The people at Holley can only offer to sell me new Quick fuel 450s or there new FI tunnel ram set up.....oh well. Thanks again all.

-

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 107

- Views

- 2K

- Replies

- 6

- Views

- 388