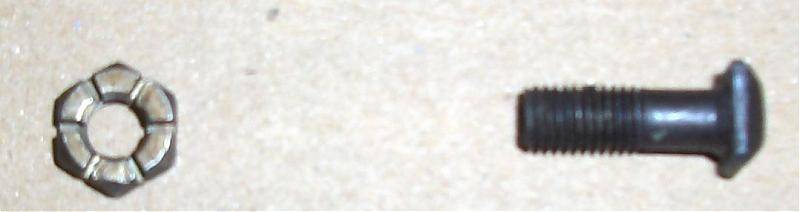

Hello, I'm in the process of converting my 69 Barracuda to a 4 speed. We're now working on the steering column. I have a donor manual transmission column and have swapped the collars on the original column. We've made some good progress, however, we cannot figure out where and what the two bolts on the top collar are used for. Based on the documentation in the shop manual, we have them in the right place, however if you notice by the attached picture, each bold has about a 1/4" that is not threaded. We have all the original parts and pieces from both columns, and can't seem to figure out what they are used for. I've also attached a picture of the original collar with the column shift, the red circles indicate where the bolts go.. Outside of the column shift, it is identical to the manual transmission column.

Any help you can provide would be appreciated.

Thanks.

![collar1 [640x480].jpg collar1 [640x480].jpg](https://www.forabodiesonly.com/mopar/attachments/collar1-640x480-jpg.77504/)

Any help you can provide would be appreciated.

Thanks.