Morning all

I have been reading threads on here for months as we build our dart and work on a few other Mopar projects at the same time. I usually dont like to post as if you search long enough you can find your answers. However this time I am stumped.

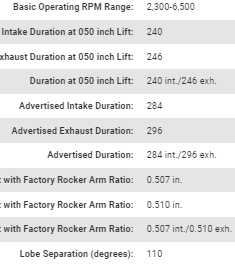

Here is what we are working with: We my 13 yr old and I, have built a 360 for our dart, we have replaced the pistons, rings, ( New Thumper cam and lifers / valve springs to match the cam as suggested by comp cams), New valve seals, new timing gears ( Set dot to dot, with the #1 cylinder at DTC), New elderbrock intake and holey 4150 double pumper carb, oh and long tube headers . I think that is all of the main components we installed.

We set the dist where is looked good for an inital start, and timing as close as you can for your inital start, we seemed to have gotten lucky and she fired right up, ran it at 2000 RPM to break in the cam, all was going well. Did the break in for 20 min, everything looked well, no leaks that were major, just tighten up some hose clamps.

So now lets set the timing. Here is where it goes bad. The timing is WAY retarded, We double checked TDC #1, just with a wooden dowel ( I am making a piston stop today and will make the proper mark tonight), no matter how much we turned the dist it would not come past 10* ATDC. It idled well, but any amount of throttle and she broke up. We triple checked the firing order, making sure #1 plug wire was at #1 tdc rotor button. We had wired in a MSD box and coil less dist but bc of the size we could not advance it enoough to get past 10*atdc maybe even 15.

Wanting to rule out the dist or my wiring ect I went back to the factory dist and coil. Now we could get to 1*atdc but then the engine dies if I try and go further, I could set the curb idle screw to make the engine rev higher to adjust it more but should i have too?

This would be our 4th engine build, but first mopar.

Tonight we check TDC with the piston stop, we will do a compression check. What else should I be checking. It is also the first cam we have done with this much thump, maybe it does require me to set the curb idle screw in a few turns to achieve this BTDC timing. From my reading on the site with a big cam I should be pushing 15-20* BTDC at this rate I will never get there.

Thank you in advance for the help. Below is the Cam info as I know most of the time this is asked for.

I have been reading threads on here for months as we build our dart and work on a few other Mopar projects at the same time. I usually dont like to post as if you search long enough you can find your answers. However this time I am stumped.

Here is what we are working with: We my 13 yr old and I, have built a 360 for our dart, we have replaced the pistons, rings, ( New Thumper cam and lifers / valve springs to match the cam as suggested by comp cams), New valve seals, new timing gears ( Set dot to dot, with the #1 cylinder at DTC), New elderbrock intake and holey 4150 double pumper carb, oh and long tube headers . I think that is all of the main components we installed.

We set the dist where is looked good for an inital start, and timing as close as you can for your inital start, we seemed to have gotten lucky and she fired right up, ran it at 2000 RPM to break in the cam, all was going well. Did the break in for 20 min, everything looked well, no leaks that were major, just tighten up some hose clamps.

So now lets set the timing. Here is where it goes bad. The timing is WAY retarded, We double checked TDC #1, just with a wooden dowel ( I am making a piston stop today and will make the proper mark tonight), no matter how much we turned the dist it would not come past 10* ATDC. It idled well, but any amount of throttle and she broke up. We triple checked the firing order, making sure #1 plug wire was at #1 tdc rotor button. We had wired in a MSD box and coil less dist but bc of the size we could not advance it enoough to get past 10*atdc maybe even 15.

Wanting to rule out the dist or my wiring ect I went back to the factory dist and coil. Now we could get to 1*atdc but then the engine dies if I try and go further, I could set the curb idle screw to make the engine rev higher to adjust it more but should i have too?

This would be our 4th engine build, but first mopar.

Tonight we check TDC with the piston stop, we will do a compression check. What else should I be checking. It is also the first cam we have done with this much thump, maybe it does require me to set the curb idle screw in a few turns to achieve this BTDC timing. From my reading on the site with a big cam I should be pushing 15-20* BTDC at this rate I will never get there.

Thank you in advance for the help. Below is the Cam info as I know most of the time this is asked for.