How much side play would appropriate?If side clearance is loose on the rocker arms ...they will be "tappy".

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve train noise

- Thread starter Billbo

- Start date

-

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Stamped arms are the self aligning type, you can sometimes better fit rocker hold downs which are responsible for setting the stationary position over the valve.How much side play would appropriate?

In other words some are a little bit wider then others ...and you can sometimes flip them around or even weld and grind on them to an extent. Adjustable style I set to .010 side play which is the minimum.

Last edited:

Ironracer

Gearhead

I have the MP HD stamped ones.. they rub....just a LilStamped arms are the self aligning type, you can sometimes better fit rocker hold downs which are responsible for setting the stationary position over the valve.

Another word summer a little bit wider then others or you can sometimes flip them around or even weld and grind on them to an extent. Adjustable style I set to .010 side play which is the minimum.

I do have some side play but I did not measure it. Its a small amount but 0.010" is quite small. I would say I may have 0.025" to 0.030". I will take covers off and recheck this. Is 0.040" preload excessive? Thats where I am with about one turn down on the adjuster.

Regards

Billy D...

Regards

Billy D...

I just did some research and found out that the big block pushrods push on an angle up to the rockers. I never knew that. Looks like about 3/8 of an inch offset. This would push the rocker side to side. The small blocks don't have that problem from what I see. They are perfectly straight. The small block would not have that problem. I don't think that the side play will be that critical compared to the big block setup. Someone correct me if I am wrong.

Regards

Billy D...

Regards

Billy D...

PRH

Well-Known Member

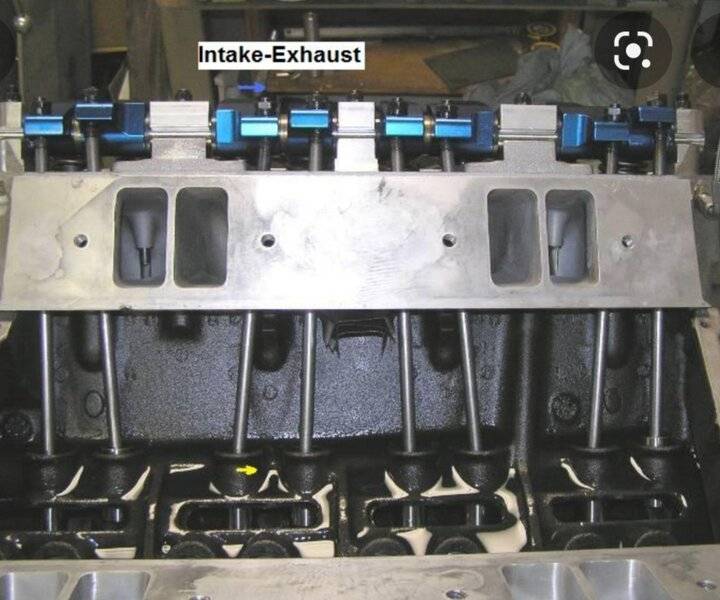

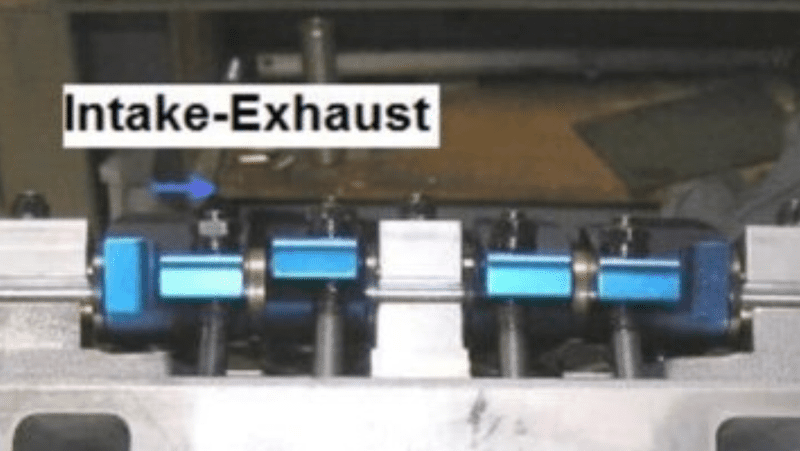

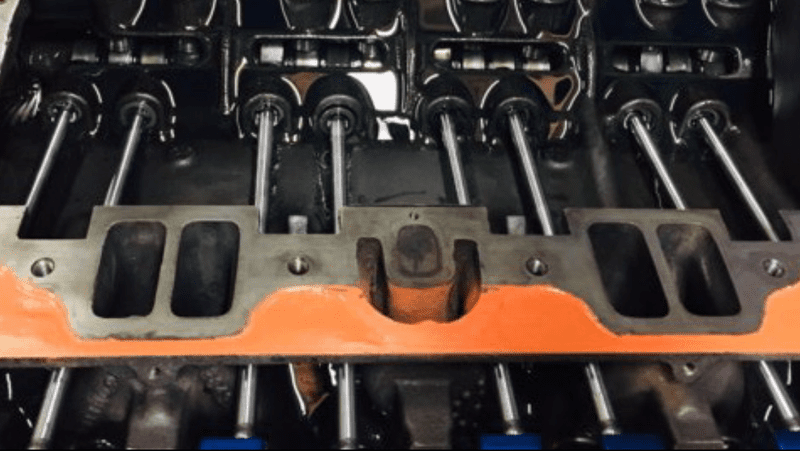

That pic of the BB is of Indy heads, which use heavily offset intake rockers.

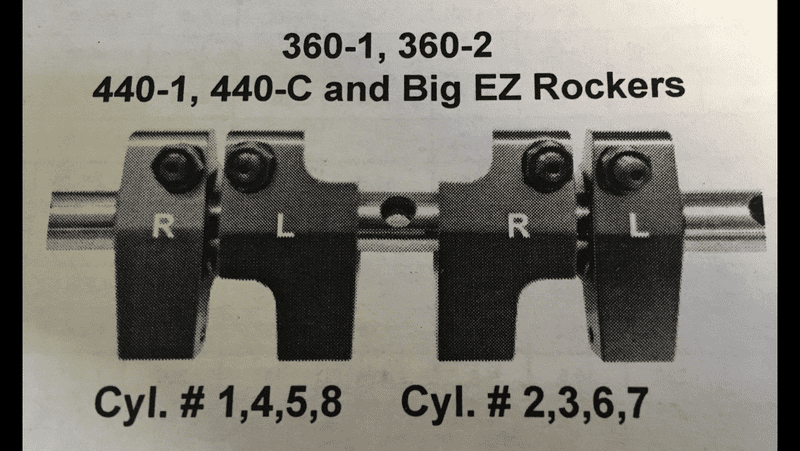

The factory BB rockers have a slight offset, which is there to allow the pushrods to be straight up and down.

Additionally, in that pic, the exhaust rockers are in the wrong positions. They would normally be swapped left to right so that the ex pushrods would be straight up and down.

The adjuster screws should end up next to each other.

The factory BB rockers have a slight offset, which is there to allow the pushrods to be straight up and down.

Additionally, in that pic, the exhaust rockers are in the wrong positions. They would normally be swapped left to right so that the ex pushrods would be straight up and down.

The adjuster screws should end up next to each other.

Last edited:

I was just pointing out that BB's are not exactly straight and SB's are perfectly straight. So side play is not as critical. Just wondering if 0.030" side play for example would be a problem in a SB.That pic of the BB is of Indy heads, which use heavily offset intake rockers.

The factory BB rockers have a slight offset, which is there to allow the pushrods to be straight up and down.

Additionally, in that pic, the exhaust rockers are in the wrong positions. They would normally be swapped left to right so that the ex pushrods would be straight up and down.

The adjuster screws should end up next to each other.

View attachment 1715919879

View attachment 1715919881

Not really a problem,I was just pointing out that BB's are not exactly straight and SB's are perfectly straight. So side play is not as critical. Just wondering if 0.030" side play for example would be a problem in a SB.

But noisier then .010 - 0.15

Isn't valve train noise your original concern?

It will be quieter at those settings then what you have now for sure.

Also I noticed my valve train was getting noisy, so just now I added a 1/4 turn to all rocker arm adjustors and it is back to normal.

George jets suggestion...ty

Mike

Last edited:

PRH

Well-Known Member

I was just pointing out that BB's are not exactly straight and SB's are perfectly straight. So side play is not as critical.

You missed the point of my post.

Which is that the BB pushrods are in fact straight up and down with heads that don’t require heavily offset rockers, like the example you posted.

Btw, when a SB uses heads that require the use of rockers with the big offset, the pushrods aren’t straight up and down on those either.

Last edited:

69FBCuda

Stand back 10' for your viewing pleasure & Safety

That's funny and f*****d up at the same time!

PRH

Well-Known Member

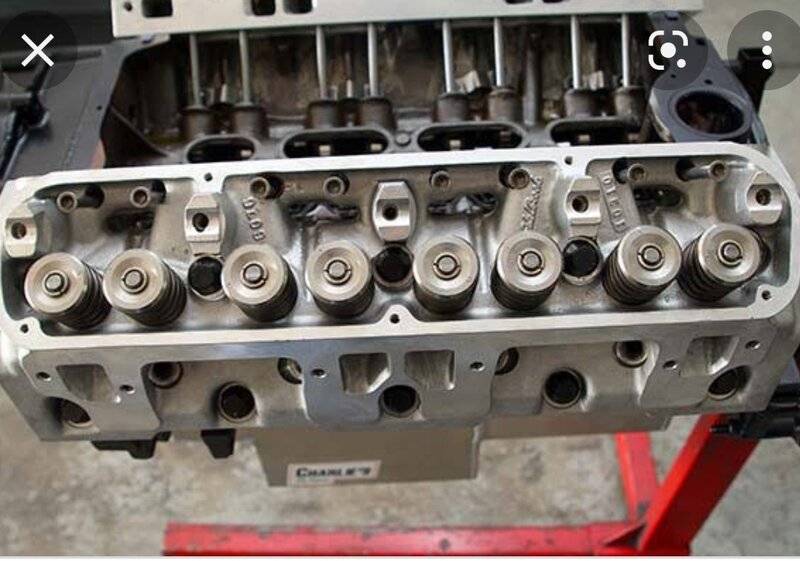

Stock BB:

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,327

Don't let someone around here see that picture...not with that rocker geometry anyway..You missed the point of my post.

Which is that the BB pushrods are in fact straight up and down with heads that don’t require heavily offset rockers, like the example you posted.

Btw, when a SB uses heads that require the use of rockers with the big offset, the pushrods aren’t straight up and down on those either.

View attachment 1715920215

PRH

Well-Known Member

Just as an “FYI”, I just test fit some Comp Ultra Pro Magnum rockers on a set of SB RPM heads using the Mancini aluminum hold downs.

That combo yields basically “0” side play(on these particular heads).

The rockers aren’t tight between the stands, but there isn’t really any play either.

I’ll be tweaking things to get some side play in there.

That combo yields basically “0” side play(on these particular heads).

The rockers aren’t tight between the stands, but there isn’t really any play either.

I’ll be tweaking things to get some side play in there.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Not that I'm insinuating you dont know this..but for the reader...If the rockers are centered over the valves but have 0 side play... just graze the hold downs sides on a bench top belt sander or the spacers .005 each side of the pair of rockers for a total of .010 clearance

Last edited:

PRH

Well-Known Member

I test fit the rockers on both heads.

The second head had just enough less space to where there was binding(fairly snug) with everything bolted down.

The bolts that come with the hold downs are too short to work on these heads IMO.

The is a touch over 1/2”(I measured .520) of space from the top of the heli-coil in the rocker stand, to the low point in the saddle.

The bolts protrude from the bottom of the shaft about .760....... leaveing about .240” of thread engagement....

which is less than the recommended minimum of being at least the same as bolt diameter(.312).

The holes in the stands are deep enough to accommodate 1/2” longer bolts(2.5” instead of 2”).

The bolt extended deeper into the stand adds some strength/stability to the stand.

The second head had just enough less space to where there was binding(fairly snug) with everything bolted down.

The bolts that come with the hold downs are too short to work on these heads IMO.

The is a touch over 1/2”(I measured .520) of space from the top of the heli-coil in the rocker stand, to the low point in the saddle.

The bolts protrude from the bottom of the shaft about .760....... leaveing about .240” of thread engagement....

which is less than the recommended minimum of being at least the same as bolt diameter(.312).

The holes in the stands are deep enough to accommodate 1/2” longer bolts(2.5” instead of 2”).

The bolt extended deeper into the stand adds some strength/stability to the stand.

I manged to find much wider rocker shaft hold downs. Im going to adjust side play to .010 - .015. After that Ill redo preload again to 3/4 turn. I measured some side play of up to 0.040 on some so ill do it properly. I did not realise the side play was critical.

Regards

Billy D...

P.S. Is 0.010" sideplay for each pair of rockers? Or 0.010" for each rocker hence 0.020" each pair?

Regards

Billy D...

P.S. Is 0.010" sideplay for each pair of rockers? Or 0.010" for each rocker hence 0.020" each pair?

Last edited:

.010 per pair.I manged to find much wider rocker shaft hold downs. Im going to adjust side play to .010 - .015. After that Ill redo preload again to 3/4 turn. I measured some side play of up to 0.040 on some so ill do it properly. I did not realise the side play was critical.

Regards

Billy D...

P.S. Is 0.010" sideplay for each pair of rockers? Or 0.010" for each rocker hence 0.020" each pair?

Sorry to ask, are you sure because other discussions have quoted 0.020" per pair..010 per pair.

Regards

Billy D...

YesSorry to ask, are you sure because other discussions have quoted 0.020" per pair.

Regards

Billy D...

.010 is where mine are.

Some will go as tight as .005 per pair.

Really .010 - .020 is fine.

Just will be a bit quieter on the tighter side.

Also check them with both valves closed on each cylinder.

Mike

PRH

Well-Known Member

Could be worn lifter bores. We have been getting 50 year old blocks in and lifter bores are worn bad. Some are wore for different reasons but age and mileage are the usual cause. The other thing we found was lifter bores were in the wrong location But that's another issue.

What I would do is check the clearance on the lifters. A loose lifter bore will cause lifter noise to come on from to much clearance and pressure bleed off. They do make different diameter lifters but usually when the are worn they are out of place or oval. Even new blocks need the bores to be trued at times. Here is a video. The method he uses to fix the bores is not recommended because it will not true the bore only resize it.

But the video will show you how bad they wear. This is always overlooked on builds. and more then none usually a problem on 50 year old blocks

my son has a bhj lifter truing fixture as used in the second video that is the proper way to do the job. something new in the shop

This video will show you the loose lifter bore in a mopar

This video is the correct way to do the job. Without this fixture the bores end up centered where they wore to.

Get ready for the red treasure mark from Rat Bastird That is his only knowledge.

What I would do is check the clearance on the lifters. A loose lifter bore will cause lifter noise to come on from to much clearance and pressure bleed off. They do make different diameter lifters but usually when the are worn they are out of place or oval. Even new blocks need the bores to be trued at times. Here is a video. The method he uses to fix the bores is not recommended because it will not true the bore only resize it.

But the video will show you how bad they wear. This is always overlooked on builds. and more then none usually a problem on 50 year old blocks

my son has a bhj lifter truing fixture as used in the second video that is the proper way to do the job. something new in the shop

This video will show you the loose lifter bore in a mopar

This video is the correct way to do the job. Without this fixture the bores end up centered where they wore to.

Get ready for the red treasure mark from Rat Bastird That is his only knowledge.

Last edited:

Oh my... am I going to have to delete this whole thread men .

Back away and forget this thread .

Back away and forget this thread .

MOPAROFFICIAL

If it has tits, it's a liabilititty.

I'll admit its entertaining to read the back n forth. The forum was kinda sorta slow..then this drew me in. Lmao. One point on a craftsmanship level of critique was what ones work looked like. My 1.6 cents 'in current Biden value' is its about function and performance. Not beauty. Though you know what a to expect when viewing some of the hack chop **** house sometimes posted. So branching from that...I thought of all the things I hear people say and then what I know myself about polishing a chamber this or that port/wall etc... where to grind on a chamber n on n on n on. I just watched the video where David vizard grinds a Vortec head chamber out to a SBC head gasket that isn't round... then I had a commenter on my own video say I should watch DV on why I shouldn't grind a 302 chamber in the area DV says not to on a VORTEC head. Different animals. People dont grasp beyond the surface. The vortec is already CAST with too much from that area. Theres nothing to remove except below the ssr and it's not necessary on the vortec due to the relation/distance of the valve seat to deck. The idea is to ascend at the top cut angle be it 30 ,37...or whatever. Someone took that and brushed across every head on the planet.Oh my... am I going to have to delete this whole thread men .

Back away and forget this thread .

Either ways... bores are round and not 5 sided like a sbc head gasket. Still like DV.. but it pays off to be the builder as well and remember things like we arent driving a flowbench down the track.

Last edited:

No, they are not. The small block has a FAR greater pushrod angle than the big block ever did. Look at the pushrod angle from the FRONT. It's ridiculous.I was just pointing out that BB's are not exactly straight and SB's are perfectly straight. So side play is not as critical. Just wondering if 0.030" side play for example would be a problem in a SB.

-