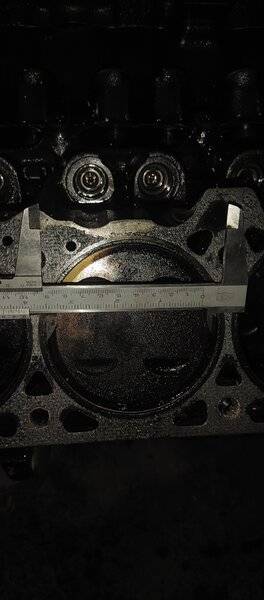

What heads? If you're talking Speedmaster, they have 65cc combustion chambers (claimed). Those pistons look about 1/10 down the hole, so say .090 - that's another 18cc. Assuming .039 for the gasket and a couple cc for the valve reliefs, your compression ratio is about 7.9 to 1. With compression that low, I'd think about calling Hughes and asking about their Whiplash cam that they claim is designed to build cylinder pressure in low cr engines. If the bores are good you could replace the pistons with ones that run at zero deck, that would raise the cr to about 9.5 to 1 assuming everything else stays the same.

I have the XE268 in a 318 with KB flat tops and 302 casting heads with bigger valves (1.88/1.60) and mild porting, runs really strong. My calculated cr is about 9.8 - runs really nice at that cr but I have no idea how it would run down around 8.