I got it up to 3300-3400, when it started to break up (and has been all along).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why are my distributor cap terminals burnt?

- Thread starter Righty Tighty

- Start date

-

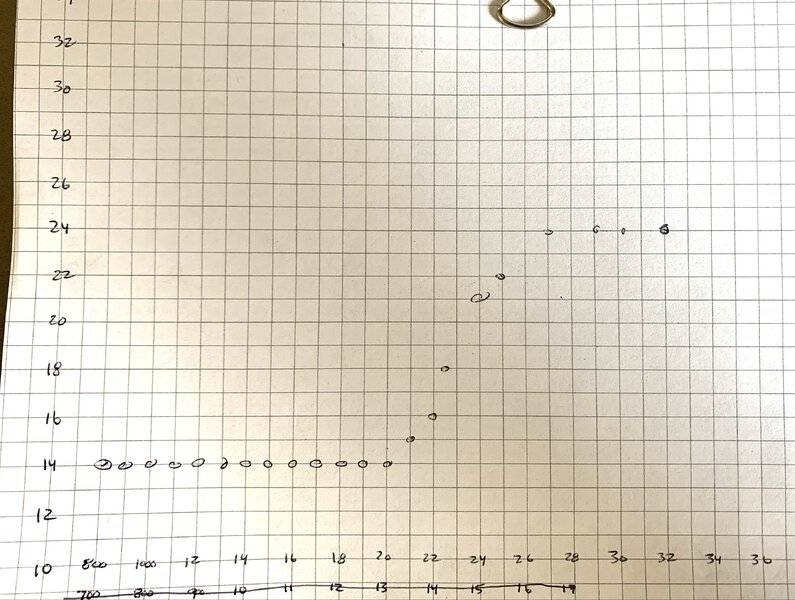

Here's a little graph I made during the test. Advance on the left, RPM along the bottom.

It’s the Summit electronic distributor, part number SUM-851008.That's pretty good what distributer do you have?

Also have you run to 6K to see where it is there?

The main issue I’ve been struggling with is that the engine hits 3400 RPM and stumbles. I can’t get the engine to rev any higher than that.

Mattax

Just the facts, ma'am

I think its way off.

However at least now you know what the timing engine is seeing.

I'm going to assume the polarity is correct.

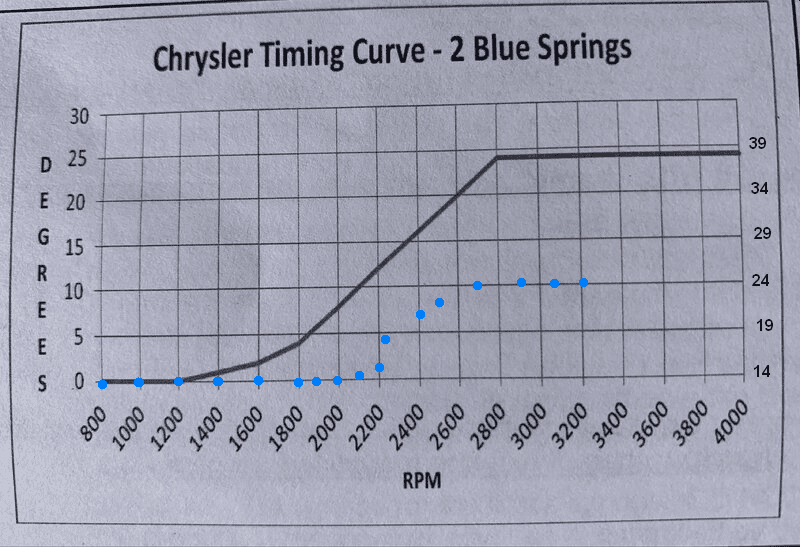

Now you actually know what the advance looks like with two blue springs and the advance limit set the way it is.

I'm not sure what to suggest abou the breaking up other than I don't think its the timing. 24* at 3000 rpm I'd expect to be sluggish but not breaking up.

It could be ignition related ECU or coil or even secondary wires or cap and rotor.

It could be fuel, running low in the bowl or not getting flow through at top of transition or begining the mains circuit.

However at least now you know what the timing engine is seeing.

I'm going to assume the polarity is correct.

Now you actually know what the advance looks like with two blue springs and the advance limit set the way it is.

I'm not sure what to suggest abou the breaking up other than I don't think its the timing. 24* at 3000 rpm I'd expect to be sluggish but not breaking up.

It could be ignition related ECU or coil or even secondary wires or cap and rotor.

It could be fuel, running low in the bowl or not getting flow through at top of transition or begining the mains circuit.

Mattax

Just the facts, ma'am

No way to know who set the perches and limit up. Could have been done back in China for all we know.

Simply not worth trusting the curves Sunnit suppli

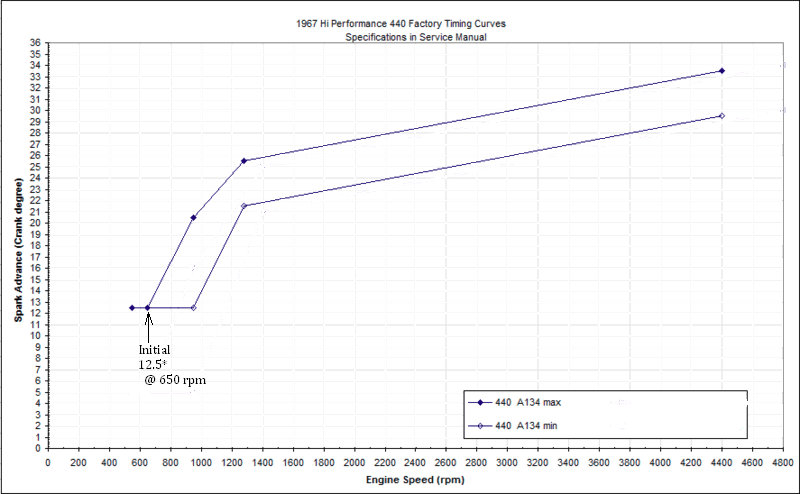

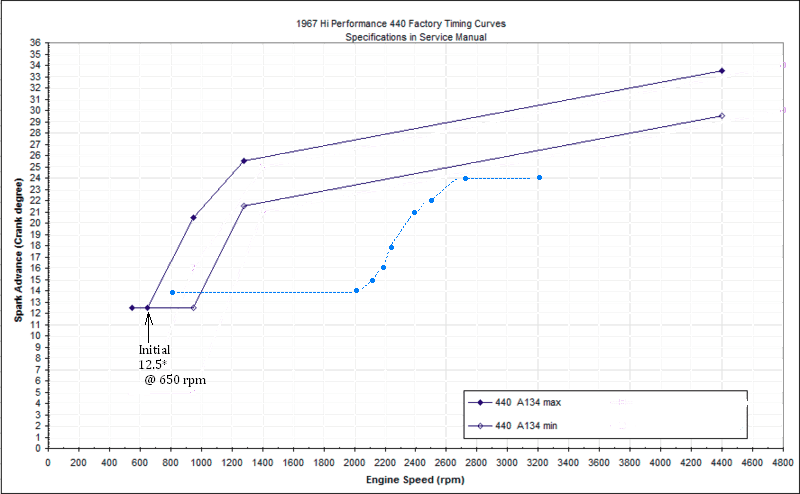

If he can get the timing somewhat close to a factory high performance curve, that should be a decent tune.

Simply not worth trusting the curves Sunnit suppli

Its a factory 440,The timing may not be right but the curve is good.

What's the actual specs of your build?

If he can get the timing somewhat close to a factory high performance curve, that should be a decent tune.

Mattax

Just the facts, ma'am

As far as timing curve goes

Lets see what would make sense for the next trial.

It there's nothing obviously wrong with the distributor (cap rotor wires pickup)..

First check will be a mechanical measurement of the advance limit. Use the keys or drill bit.

If you want to go step by step, accept that for what it is right now.

Change one of the springs for a black spring, which I beleive is the longest.

It should be a little loose, no tension upon installing. If so, great.

^This will result in just one blue spring holding the advance back at idle.

Therefore timing should begin advancing at a lower rpm.

Optional trial sequence.

If having a 10* limit is just driving you bonkers.

Increase advance limit to what you think will be 20 degrees instead of 10.

That will put a lot more tension on the springs.

That will delay the begining of th advance to a higher rpm. Opposite of what we want.

Therefore

Change one of the springs for a black spring, which I beleive is the longest.

It should be a little loose, no tension upon installing. But it may not be.

Therefore bend the perch just enough inward so the black spring is loose.

Going this route its hard to predict whether this will be enough to get the advance to begin at a lower rpm.

Either way, retest and see what the results are.

Lets see what would make sense for the next trial.

It there's nothing obviously wrong with the distributor (cap rotor wires pickup)..

First check will be a mechanical measurement of the advance limit. Use the keys or drill bit.

If you want to go step by step, accept that for what it is right now.

Change one of the springs for a black spring, which I beleive is the longest.

It should be a little loose, no tension upon installing. If so, great.

^This will result in just one blue spring holding the advance back at idle.

Therefore timing should begin advancing at a lower rpm.

Optional trial sequence.

If having a 10* limit is just driving you bonkers.

Increase advance limit to what you think will be 20 degrees instead of 10.

That will put a lot more tension on the springs.

That will delay the begining of th advance to a higher rpm. Opposite of what we want.

Therefore

Change one of the springs for a black spring, which I beleive is the longest.

It should be a little loose, no tension upon installing. But it may not be.

Therefore bend the perch just enough inward so the black spring is loose.

Going this route its hard to predict whether this will be enough to get the advance to begin at a lower rpm.

Either way, retest and see what the results are.

If he can get the timing somewhat close to a factory high performance curve, that should be a decent tune.

Agreed.

The only picture I have is when I took the rotor off, but hadn't taken the plate off between the rotor and weights.What advance mechanism does that distributer use? Pics?

I wish I knew. Like Mattax said, it seems to be pretty close to a factory 440 by the measurement I got on the cam, but that's really all I know. Six pack, iron heads.What's the actual specs of your build?

What I can't figure out is why I would only get 10* mechanical. I'm going to add a black spring tomorrow and see what that does.

Check the air gap on all 8 reluctor tips. I used the same type of dist last year & found the reluctor was machined out of round. Rel teeth almost made contact [ misfire when that happens ] with p/up. Found another reluctor & it was ok, uniform air gap.

Also check for shaft wobble, it can close up the gap, especially as rpm increases, from centrifugal force.

Also check for shaft wobble, it can close up the gap, especially as rpm increases, from centrifugal force.

Thanks, I will check the gaps. However, I will say that I had the same performance issue with the old distributor (this is brand new).Check the air gap on all 8 reluctor tips. I used the same type of dist last year & found the reluctor was machined out of round. Rel teeth almost made contact [ misfire when that happens ] with p/up. Found another reluctor & it was ok, uniform air gap.

Also check for shaft wobble, it can close up the gap, especially as rpm increases, from centrifugal force.

I decided today that before I pulled the distributor, I'd take a look at the vacuum pods and check function. Long story short, the rear pod has a "gummy" or "sticky" feel to it. It does move under vacuum, but not smoothly and does not return to position easily. The front pod is very different. It's smooth and I can depress the "arm" that goes into the pod easily, and it returns to position on its own.

I disconnected/plugged the vacuum line to the rear, and HOLY SMOKES, it's like I'm driving a different car. Acceleration using a heavy foot is night and day different. This was the first time I've been able to put the pedal on the floor and hear the transmission downshift -- before it wouldn't even get to the point of downshifting before sputtering and misfiring. However, it still stumbles at higher RPM, so I'm going to pull the distributor and take a look at the aforementioned items.

I have so many darn threads going on about this car that I wish I could consolidate into one.

I disconnected/plugged the vacuum line to the rear, and HOLY SMOKES, it's like I'm driving a different car. Acceleration using a heavy foot is night and day different. This was the first time I've been able to put the pedal on the floor and hear the transmission downshift -- before it wouldn't even get to the point of downshifting before sputtering and misfiring. However, it still stumbles at higher RPM, so I'm going to pull the distributor and take a look at the aforementioned items.

I have so many darn threads going on about this car that I wish I could consolidate into one.

Mattax

Just the facts, ma'am

Assume you're talking about the outboards carbs on the 6-pak.I'd take a look at the vacuum pods and check function. Long story short, the rear pod has a "gummy" or "sticky" feel to it. It does move under vacuum, but not smoothly and does not return to position easily. The front pod is very different. It's smooth and I can depress the "arm" that goes into the pod easily, and it returns to position on its own.

I disconnected/plugged the vacuum line to the rear, and HOLY SMOKES, it's like I'm driving a different car. Acceleration using a heavy foot is night and day different. This was the first time I've been able to put the pedal on the floor and hear the transmission downshift -- before it wouldn't even get to the point of downshifting before sputtering and misfiring. However, it still stumbles at higher RPM, so I'm going to pull the distributor and take a look at the aforementioned items.

I have so many darn threads going on about this car that I wish I could consolidate into one.

That's good. Now you've isolated a problem. Leave them disconnected for now. It will work fine on two barrels, certainly for street use.

Yes, sorry. I’m talking about the outboards on the six pack.Assume you're talking about the outboards carbs on the 6-pak.

That's good. Now you've isolated a problem. Leave them disconnected for now. It will work fine on two barrels, certainly for street use.

I only blocked the rear, running on the center carb and front outboard. So essentially running a 4-barrel, assuming the front is opening.

I agree, I’ve isolated a problem, perhaps not necessarily THE problem. I suspect there are multiple things going on here, and next up is the distributor.

I wish I could better describe what is happening when it hits higher RPM. There’s a guy not far from me who works on older cars, maybe I’ll pay him a visit. Simply because it might be easier for an experienced ear to identify the sound as opposed to me trying to describe it.

bee1971

Well-Known Member

Yes , that’s Summits and Jegs version or name on the Firecore DistributorThat looks rings a bell but not from a Mallory or MP Mallory distributor.

Whose name on the distributor? edit. Bet its a Firecore. yes?

Can you take a photo of the springs? If they are what I think they are, they are not the same as the ones in my photos above.

Started reading from the original post

bee1971

Well-Known Member

Righty Tighty

Are you familiar on how to adjust the mechanical advance on that distributor ?

You don’t use the limiter plate with this distributor

Like Mattix stated , you loosen those two Allen screws and open or close those two tabs on the plate for mechanical advance on how many degrees you want

Factory blue springs , timing all in by 2400 RPMs

I run 16 initial with 18 mechanical for a total of 34 Degrees with ported vacuum at cruise

Are you familiar on how to adjust the mechanical advance on that distributor ?

You don’t use the limiter plate with this distributor

Like Mattix stated , you loosen those two Allen screws and open or close those two tabs on the plate for mechanical advance on how many degrees you want

Factory blue springs , timing all in by 2400 RPMs

I run 16 initial with 18 mechanical for a total of 34 Degrees with ported vacuum at cruise

Last edited:

bee1971

Well-Known Member

Two Distributors , same issueThanks, I will check the gaps. However, I will say that I had the same performance issue with the old distributor (this is brand new).

Have you tried a different combination of Coil or ECU ?

I had the same issue , but mine was cutting out closer to 4500-5000 RPMs

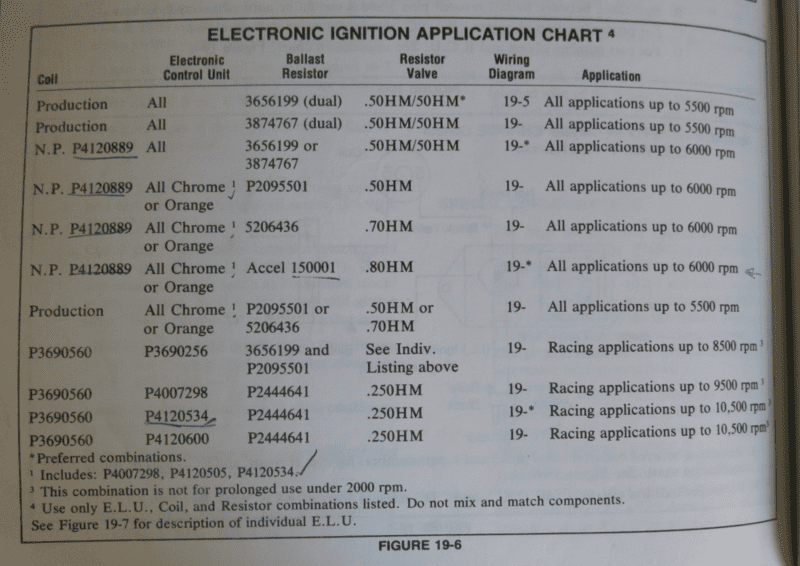

Have a picture of the ecu? They are rated for different RPM ranges and also matched with a certain ballast resistor value. just a example.

I don’t have a picture handy, but it’s one of the light blue boxes I got from you a while back. I won’t be home until tomorrow to check the resistor, but would that drop the range all the way down to 3400?Have a picture of the ecu? They are rated for different RPM ranges and also matched with a certain ballast resistor value. just a example.

View attachment 1715879685

If over 1.5 ohm possibly. If not I will send you a new one.

-