TrailBeast

AKA Mopars4us on Youtube

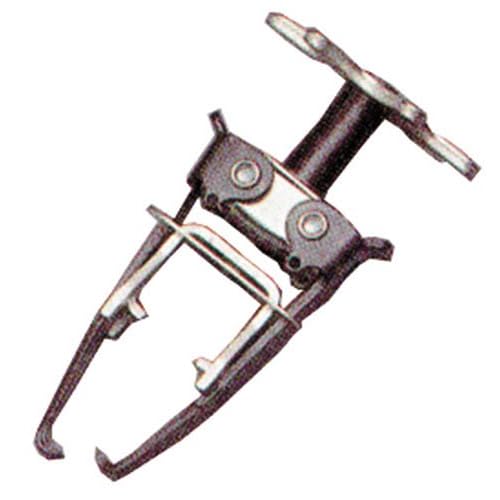

Technology has changed quite a bit over the years and I read about guys needing to get valve springs and retainers off with the head still on the engine.

These days most use compressed air to keep the valves in place while removing retainers and springs.

In the "Old Days" we used to get the piston coming up just a bit before TDC and feed about a 8-10 inches of 1/4in nylon rope through the spark plug hole into the cyclinder, leaving a bit hanging out of the plug hole.

Then continue rotating the engine by hand until the piston pushed the rope up tight into the combustion chamber to hold the valves so you could remove the retainers and springs.

Works great for changing springs or guide seals.

When that cylinder is done, turn the engine back a little and pull the rope out and go to the next one.

These days most use compressed air to keep the valves in place while removing retainers and springs.

In the "Old Days" we used to get the piston coming up just a bit before TDC and feed about a 8-10 inches of 1/4in nylon rope through the spark plug hole into the cyclinder, leaving a bit hanging out of the plug hole.

Then continue rotating the engine by hand until the piston pushed the rope up tight into the combustion chamber to hold the valves so you could remove the retainers and springs.

Works great for changing springs or guide seals.

When that cylinder is done, turn the engine back a little and pull the rope out and go to the next one.