Wolfgang,

NAPA shows a squareback housing. This will work with grounding the second brush. In theory these can have a slightly better output, but in reality it depends on the components inside and how close they fit etc. The listing says its rated for '35 amps'. Usually ratings are done to indicate maximum output (higher rpm).

So if 35 amps is near maximum, then this is not the right alternator for your car.

The alternator for your car ('69 w/ air conditioning) should be capable of producing 40 amps at 15 volts when the engine is at 1250 rpm.

In 1969 Chrysler described or rated that alternator as a 46 amp alternator, and the standard one with v-8s as 37 amps.

see here:

https://www.hamtramck-historical.com/images/dealerships/DealershipDataBook/1969/69_Barracuda0021.jpg

We don't know how they came up with the ratings but the method was probably consistant across the Chrysler product line.

The next two links look more promising. However I see in the reviews that some customers received alternators that don't look like the ones pictured.

Let me go find the last thread I recall about your car's electrics.

OK here:

Burned bulk head connection

Maybe we can figure out what isn't working.

Maybe the first check once the battery is charged is whether the rotor is getting power.

With key in run, check the voltage at the positive field terminal.

It should be the same voltage as the battery.

If not, then check for voltage at the regulator's input.

[Try not to leave the key in run very long ubless the engine is running.]

If there is power at the positive field terminal, then whether the alternator works at all can be checked by supplying the field with power.

An insulated jumper from the battery to the field terminal will work.

Make sure the conductor doesn't touch ground!

Easiest place to attach to the power circuit is probably at the alternator Batt terminal.

A few other tests can be done with the wires disconnected. On the bench is easiest.

Checks

field circuit for short to ground.

field circuit for internal open. To do this , remove the ground brush, and touch probe to the slip ring.

Visual check of the brushes, terminals and insulators.

If its none of those, then its probably diodes or an open stator.

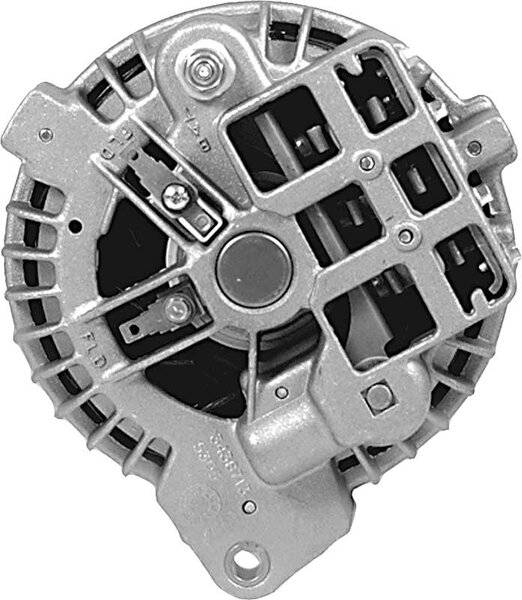

Looking back and one thing that puzzles me is why there is a terminal tab on the second brush?

A '65 housing should only have one insulated brush holder. The other should be cast in place.