Thick or Thin head gaskets? Can I get some input on which ones I should run? Is this a controversial topic? If not I'll start a new thread with a more controversial topic

Engine - 1968 340

Pistons- 30 over TRW pistons that are avg of 12 thousandths over? (I think that's how it was stated)

Heads- heavy *** X heads

Springs- comp 901

Rockers - Stock

Rods- straight pieces of metal that are stock?

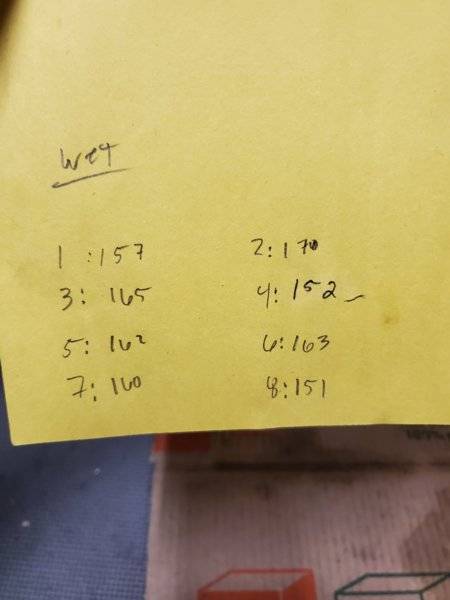

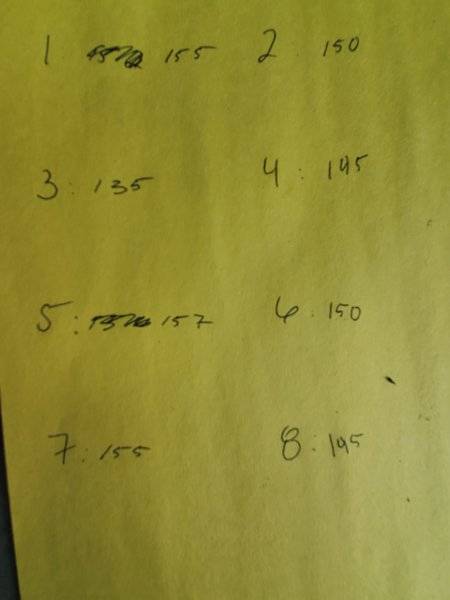

Compression- pictured below 135-157

Camshaft- Summit 1789 (cam card pictured)

Hooker comp headers

RPM 7576 Air Gap

2.5in exhaust

Need anything else?

The car had some engine tech 7J gaskets on it (measuring thickness tomorrow) and I have some felt pro 8355pt which are .053 thickness. Or should I get thinner head gaskets?

Engine - 1968 340

Pistons- 30 over TRW pistons that are avg of 12 thousandths over? (I think that's how it was stated)

Heads- heavy *** X heads

Springs- comp 901

Rockers - Stock

Rods- straight pieces of metal that are stock?

Compression- pictured below 135-157

Camshaft- Summit 1789 (cam card pictured)

Hooker comp headers

RPM 7576 Air Gap

2.5in exhaust

Need anything else?

The car had some engine tech 7J gaskets on it (measuring thickness tomorrow) and I have some felt pro 8355pt which are .053 thickness. Or should I get thinner head gaskets?