ValiantRacing

Well-Known Member

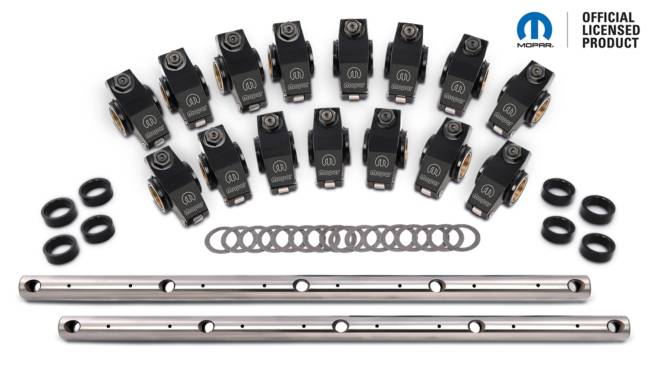

Anybody use these or have any info on them, are they any good?

Link?

So, are they just Proform rockers in black with a Mopar logo and twice the price?

Whoops, I take that back. The standard blue ProForm rockers have needle bearings. That's a big thumbs up for the black Mopar logo rockers in my book.

Looks like they're not bushed at all (good luck with that). Looks like the extra $120 buys you bronze bushings and a pretty Mopar logo.

View attachment 1715509961

I do like how they are bushed instead of needle bearings.

What is the reason everyone is wanting the bushings on a rocker arm that has an aluminum body?

Might as well go with the 440 source for 275$.The bronze bushings alone are worth the extra expense....at least to me. They make them for big block too so I bookmarked them.

Aluminum alone is in general a poor performer as a plain bearing material compared to bronze or other materials. You will never see a aluminum used to bush a steel part unless there was no other option or the person doing the work didn't know better. Will it work, maybe/probably. Is it a better choice than bronze? Absolutely not.

Then why don't don't all aluminum pistons have bronze bushing inserts? Or aluminum connecting rod pin bores? Or main and rod bearings for that matter? That is why I question it.

How many of you guys that don't like needle roller rockers have ever had a good roller rocker like Harland Sharp or Jesel come apart on you? Huh? How many? And if so was it the rockers fault or your poor installation?

Pistons are not a bearing fit tolerance in the cylinder bore, the rings are in hard contact. Can't answer the others, I've seen some that do and some that don't. I would put bronze in anything that wasn't getting regular tear down and inspection. I'm sure there are coatings that help too. It probably comes down to cost and required durability in most cases.

Looks like they're not bushed at all (good luck with that). Looks like the extra $120 buys you bronze bushings and a pretty Mopar logo.

View attachment 1715509961

I didn’t see the price, but I’d use them if the cost was reasonable. They are bushed which is one reason why they cost more. I think I’d look at a set of PRW stainless rockers too. You can get them in 1.6 ratio too.