pishta

I know I'm right....

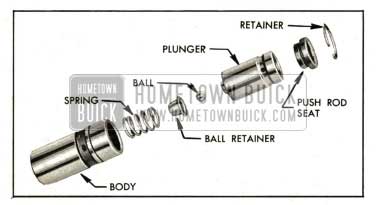

There is crap in them. Lifters are simple pimple: there is a piston+pushrod seat, a little check ball/spring in a retainer and a larger spring at base. If you pop the little cage off the bottom of the plunger, youll see the tiny spring and the ball bearing. If you have a soft lifter sitting in oil and your pumping it with a pushrod, I guarantee you have some crap in the ball seat (or ball is not even seating due to tiny spring in retainer) as the tolerances of the pistons are pretty tight.

Last edited: