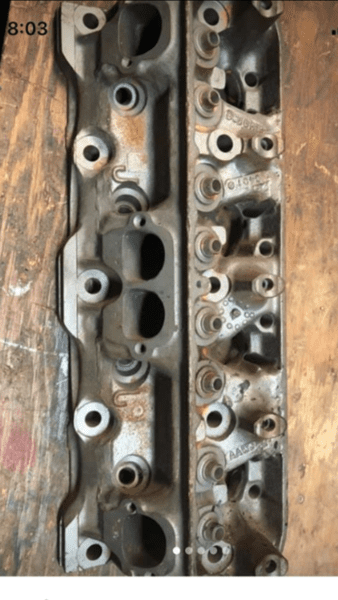

So I seen on Facebook someone has a set of j heads with w2 ports. His “welded up j heads with w2 exhaust ports. And offset pushrods. “ my Initial thought is would this would the water jackets match ? The w2 has very unique port design that’s a lot of material to take off of a j head ? It’s definitely something I haven’t seen before in many years or building sbm

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welded j heads/w2

- Thread starter Moparhead

- Start date

-

I'm almost at a loss for words on this one, I guess just because someone is able to do some things doesn't necessarily mean that they should! I'm suspecting powder flow oxy/accetylyne welding that uses the cast iron powder. That stuff weren't cheap the last time I checked, but who knows? They could be porting and machining a lot of iron and saving it and mixing it with boric acid to flux it and welding it back in. Or maybe someone found a shipping container full of Ni-Rod welding rods. Applying it back in a little at a time after nearly grinding out the whole port and duplicating a W2 exhaust port reminds me of the stories about former P.S. driver Lee Sheperd using hundreds of feet of aluminum TIG rod to make a big chevy pro stock head that worked on both NHRA and IHRA mountain motor classes. All I can think is why they didn't just get some high swirl 360 heads. This may be very well a good example of "Too much sense for one person but not enough for two"...

Last edited:

MOPAROFFICIAL

Oogliboogli

Damn. Laughing in pitty for the guy who had to do all that work. Cha'ching

I was at a loss for words ! I’ve never ever seen anything like this. I mean all this work is just buy the w2s LOLI'm almost at a loss for words on this one, I guess just because someone is able to do some things doesn't necessarily mean that they should! I'm suspecting powder flow oxy/accetylyne welding that uses the cast iron powder. That stuff weren't chep the last time I checked, but who knows? They could be porting and machining a lot of iron and saving it and mixing it with boric acid to flux it and welding it back in. Who knows? Maybe someone found a shipping container full of Ni-Rod. Applying it back in a little at a time after nearly grinding out the whole port and duplicating a W2 exhaust port reminds me of the stories about former P.S. driver Lee Sheperd using hundreds of feet of aluminum TIG rod to make a big chevy pro stock head that worked on both NHRA and IHRA mountain motor classes. All I can think is why they didn't just get some high swirl 360 heads. This may be very well a good example of "Too much sense for one person but not enough for two"...

"It's definitely worth something"

Dude, if you think that, I have a never ending supply of cat crap for you, too.

Dude, if you think that, I have a never ending supply of cat crap for you, too.

Right tho! I honestly was hoping he would try to run it"It's definitely worth something"

Dude, if you think that, I have a never ending supply of cat crap for you, too.

This is what happens in the winter time. Idle hands are the devils work. I hope it was all just extra material hanging around collecting dust he decided to just to burn time away in his snowy winter wonderland garage.

MOPAROFFICIAL

Oogliboogli

Can one of you tell the story behind these heads a little more?

I quit fakebook almost a decade ago, talk about life tracking, stealing, meddling, divorce, death... I reccomend to everyone I care about...to not use fakebook.

Are they clay? Painted balzoa? Lol

I quit fakebook almost a decade ago, talk about life tracking, stealing, meddling, divorce, death... I reccomend to everyone I care about...to not use fakebook.

Are they clay? Painted balzoa? Lol

nm9stheham

Well-Known Member

Looks like the kind of work done regularly on 351C exhaust ports back-in-the-the-day. Those had miserable exhausts with a sharp and narrow bend over a water jacket area under the exhaust ports. There were a number of work-arounds with epoxy (eventually would fail), inserts, and welding. It was 100% worth the effort on those heads 'cuz the intake ports were already so darned good for the times.

IDK on these...without results, I'd hesitate to pass judgement one way or the other.

IDK on these...without results, I'd hesitate to pass judgement one way or the other.

yellow rose

Overnight Sensation

I don't get it. The intake port is weak, so someone spent all that effort to fix the exhaust port. Now you've got an exhaust port flowing at least as good as the intake port, most likely better.

Makes no sense to me.

Makes no sense to me.

I actually had a friend send it to me tbh I don’t have a Facebook this is as advanced as I get lol. The person with the heads was asking for info on them lol. So what I figured he got suckered on the heads.Can one of you tell the story behind these heads a little more?

I quit fakebook almost a decade ago, talk about life tracking, stealing, meddling, divorce, death... I reccomend to everyone I care about...to not use fakebook.

Are they clay? Painted balzoa? Lol

I thought they may have cut into a water jacket. That’s a lot of material. I’m going to ask my dad he’s been building engines and basically have abodys for ever.Looks like the kind of work done regularly on 351C exhaust ports back-in-the-the-day. Those had miserable exhausts with a sharp and narrow bend over a water jacket area under the exhaust ports. There were a number of work-arounds with epoxy (eventually would fail), inserts, and welding. It was 100% worth the effort on those heads 'cuz the intake ports were already so darned good for the times.

IDK on these...without results, I'd hesitate to pass judgement one way or the other.

I mean we can hope but I’m pretty sure the guy wanted to run them lol. My question was why lol had to bring it here tho.This is what happens in the winter time. Idle hands are the devils work. I hope it was all just extra material hanging around collecting dust he decided to just to burn time away in his snowy winter wonderland garage.

PRH

Well-Known Member

Maybe........

“I have some W2 headers that I reeeeaaaalllyy want to use”

“I have some W2 headers that I reeeeaaaalllyy want to use”

MOPAROFFICIAL

Oogliboogli

If the LA had no dogleg wall, was straight... they are more than capable of flowing 300 cfm by .550.

I've seen 290.3 @.530 lift before on a set of fully worked w/2.02 j heads.

I found the notes today while working through the piles of **** in my garage.

They did @28 4" bore 2.02

.100 -76

.200-147

.300-204

.400-252

.500-284

.530-290.3

.550-269

.600-249

Saturation 249

I always "search" after the the basic .100 increments are noted, because you see some magical **** at odd lifts...

You need a good exhaust port for that.

Oh, Also found an old Kar kit manual..lol

I've seen 290.3 @.530 lift before on a set of fully worked w/2.02 j heads.

I found the notes today while working through the piles of **** in my garage.

They did @28 4" bore 2.02

.100 -76

.200-147

.300-204

.400-252

.500-284

.530-290.3

.550-269

.600-249

Saturation 249

I always "search" after the the basic .100 increments are noted, because you see some magical **** at odd lifts...

You need a good exhaust port for that.

Oh, Also found an old Kar kit manual..lol

Wyrmrider

Well-Known Member

Sounds like the amount of work on the AMC Pro Stock Heads

Nice flow numbers! I imagine the OP's post is what a set of 576 that only had the exhausts fully worked would look like.

MOPAROFFICIAL

Oogliboogli

I'm looking real hard to find where it says 9:15 in those casting numbers there and I don't see it I kind of want to say this it's obvious already that those intake ports are nowhere near stock they're offset and probably W2 as well. How about if you have a Set of early W-2s and they cracked to ****... so you literally carve out the exhaust and intake ports and weld them into a set of J heads.... ? Crazy talk. ..then mill the whole damn thing square again.idk... there are a few hard ways to go about a torturous endeavorNice flow numbers! I imagine the OP's post is what a set of 576 that only had the exhausts fully worked would look like.

PRH

Well-Known Member

The head with the w2 looking ex ports still appears to have the intake pushrod holes in the original location.

Looks like an awful lot of welding at the valve cover rail on those heads, too. And it does look like there is welding and the push rod holes around the intake ports have been welded on and hacked at. I'm starting to fear you may be exactly right about the "W2 Conspiracy Theory". I believe it would have been easier just to start a backyard foundry and cast them from scratch. The same degree of labor intensity either way you go, it absolutely is making my head swim thinking about the preheating cooling, machining, carbide usage, and God knows what else it would take.

Last edited:

PRH

Well-Known Member

And it does look like there is welding and the push rod holes around the intake ports have been welded on and hacked at.

I had to go back and look.

When I said it looked like the pushrod holes were stock...... I was looking at the exhaust pushrod holes.

RAMM

Well-Known Member

I had to go back and look.

When I said it looked like the pushrod holes were stock...... I was looking at the exhaust pushrod holes.

So much wasted time and effort when the problem is the small shallow bowls, good luck welding and changing that. Still a helluva a valiant effort. J.Rob

MOPAROFFICIAL

Oogliboogli

I agree with you on the bowls, though some can go big. Its starting there.. so you dont waste time finding out its junk with a hole in the bowl.So much wasted time and effort when the problem is the small shallow bowls, good luck welding and changing that. Still a helluva a valiant effort. J.Rob

Can no one find any more pictures of these boat anchors?

Bighead440

Well-Known Member

-