67Dart273

Well-Known Member

The POS place I worked for the last 4 years building electronics layed me off. During the "pandemic" I've been working at home building up the last (ever) of the now obsolete drive modules. The thing that's stupid is, that now they will only be selling chairs with 3rd party electronics, so the only work up in electronics will be various switchboxes and interconnect cables. VASTLY reduced workload. The last few times I've been out there the woman (who doesn't GAS and makes lots of mistakes) has been running around trying to look busy---she's full time. So naturally they fired me and kept her. Would have been the perfect thing for me to carry on---work 2 days a week, if I got behind, could work 3 for a couple weeks. Oh well.......................................

Some time ago, "in the home bunker" building hand controls

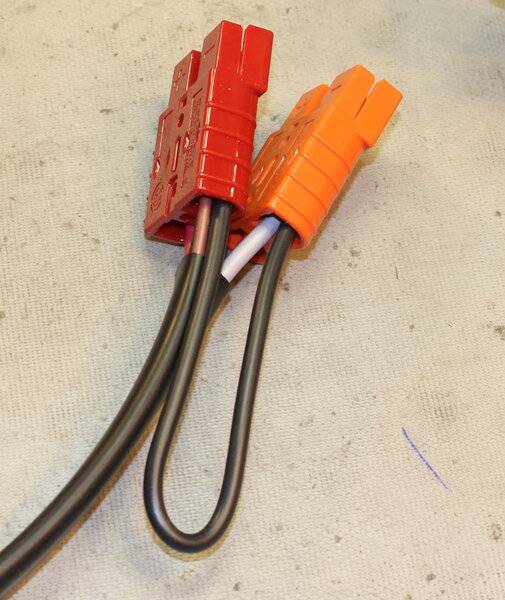

Building module power cables at home. The last 6 or 8 were built by "the other woman"---and I had to tear them apart as they were made WRONG

Building a drive module Took the last two that will ever be built to work this morning, they were 48V

Some time ago, "in the home bunker" building hand controls

Building module power cables at home. The last 6 or 8 were built by "the other woman"---and I had to tear them apart as they were made WRONG

Building a drive module Took the last two that will ever be built to work this morning, they were 48V

Last edited: