This I will be able to check after I get the new cam which will be 460 on lobes.One more question.........

At full lift, does the pushrod oiling hole start to show above the lifter bore, and are those relief cuts on the sides of the body showing at all??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solid roller lifters...

- Thread starter Miszny

- Start date

-

Frankly if they work like this without oil pressure sacrifice I don’t see the point of extra oiling solution. Especially after many people reporting too low oils pressure.Obviously they’re working like that since there are very few negative comments about BAM lifters........but I gotta say........ I prefer the edm hole going from the band down to the axle.

The Isky Red Zones also have the hole above the axle like those BAM’s do, with a hole from the band as an option/upgrade.

Needle bearing lifters need the least amount and yet BAM offer steel bushings with the same oiling solution, obviously this does the job.

I will report on my oil pressure.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

If it uses a bush, it does need a pressurised supply. [ think: rod or m/brg ]

With a rod or main bearing the oil is supplied to the center of the bearing under pressure and works it's way out from there.

So that statement is not exactly right.

So unless the lifter is directing the oil through the bearing shaft under pressure, to the inside of the bearing, then it is not the same and not delivering under pressure.

Once the oil reaches the side of the lifter it can escape past the roller and case. Basically from there it's a dribble feed system to the inside of the bearing.

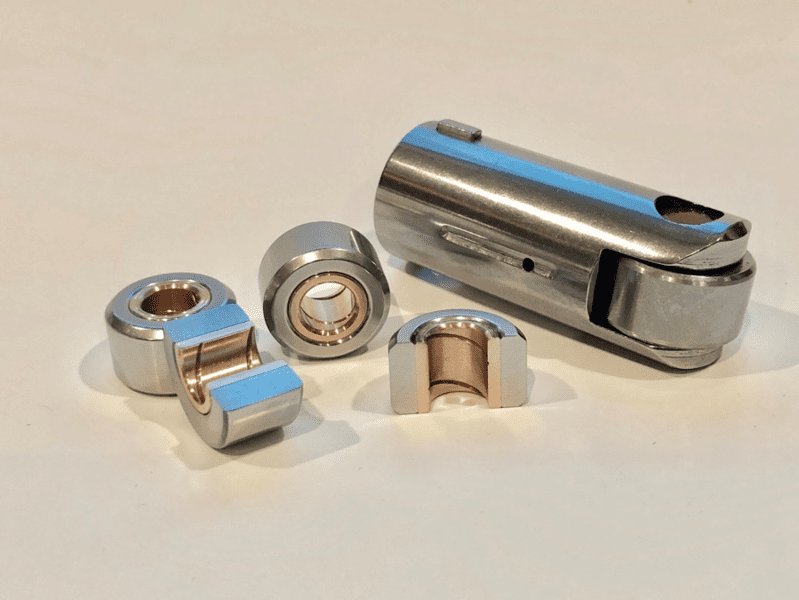

This cutaway shows how the oil is supplied.

For you Bakerlite, you might learn something.

Bosch Automotive Handbook 9th edition, 1544 pages.

Page 328 Hydrodynamic brgs: ' To ensure reliable operation of a hydrodynamic sliding brg, it is necessary for there to be a load-carrying lubricant film over a wide operating range. This lubricating film is created in a radial brg when the shaft is eccentrically positioned. This in turn generates a lubricant pressure. The rotating shaft delivers the lubricant into the brg gap.'

Bosch Automotive Handbook 9th edition, 1544 pages.

Page 328 Hydrodynamic brgs: ' To ensure reliable operation of a hydrodynamic sliding brg, it is necessary for there to be a load-carrying lubricant film over a wide operating range. This lubricating film is created in a radial brg when the shaft is eccentrically positioned. This in turn generates a lubricant pressure. The rotating shaft delivers the lubricant into the brg gap.'

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

It's not being pressure fed like a rod bearing.

There is no "pressurized oil supply " between the roller and the shaft.

The oil is just working it's way into the gap, same as if it were sitting a container of oil or if you were to squirt some oil onto it and turn the roller with your finger.

If anything it's acting more like a little end bearing..

It could receive enough oil from splash feed, if it's so efficient at sucking the oil into it..

No one is talking about the hydro wedge.. that comes after the oil gets in there.

One thing at a time Sparky..

Your wrong, simple as that..it does need a pressurised supply. [ think: rod or m/brg ]

There is no "pressurized oil supply " between the roller and the shaft.

The oil is just working it's way into the gap, same as if it were sitting a container of oil or if you were to squirt some oil onto it and turn the roller with your finger.

If anything it's acting more like a little end bearing..

It could receive enough oil from splash feed, if it's so efficient at sucking the oil into it..

No one is talking about the hydro wedge.. that comes after the oil gets in there.

One thing at a time Sparky..

Last edited:

cookietruck

Well-Known Member

isn't there pressurized oil in the lifter bore? seems the same principle that allows oil pressure (in that lifter cutaway) to reach the pushrod cup and run through the pushrod if they allow it, will allow oil pressure to reach roller bushing. surely that little oiling holing to the roller wouldn't be completely uncovered 100% of the time.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

There is a gap between the side of the roller and the case at the place where the oil passage ends, so the oil can escape there first, thus dumping pressure.

All it's doing is flooding the side of the bush and the roller with oil and that oil is working it's way in from there.. Try doing that with a rod or a main bearing and see how long it lasts.

If there was a passage along the center of the bearing shaft and up into the bush ( like how a rod bearing or shaft roller rocker worked), then you could call that as purely "pressure fed".

Notice where the oil feed ends? At the top of the shaft, because that's where the maximum clearance is between shaft and the bush for the oil to enter.

As I said, calling it pressurized like a rod or main is not exactly correct.

All it's doing is flooding the side of the bush and the roller with oil and that oil is working it's way in from there.. Try doing that with a rod or a main bearing and see how long it lasts.

If there was a passage along the center of the bearing shaft and up into the bush ( like how a rod bearing or shaft roller rocker worked), then you could call that as purely "pressure fed".

Notice where the oil feed ends? At the top of the shaft, because that's where the maximum clearance is between shaft and the bush for the oil to enter.

As I said, calling it pressurized like a rod or main is not exactly correct.

Last edited:

Bakerlite,

I am correct, simple as that. Post #81. You are a great example of cannot fix dumb....

The Bosch Handbook I quoted from lists 6 pages of contributing authors, many with 'Dr' in front of their names.

Not sure about Ch, but GM oil pressure safety switches [ warning light ] activate at 3-5 psi. Not 20, not 50 psi. That is because 3-5 psi is all that is reqd to lube the rod/main brgs at idle. The reason higher pressures are used is that the oil carries away heat; that is oil's other function. If the the pressure is insufficient, the oil stays in the brg too long & overheats. The high pressure is not reqd for lubricating, it is reqd to remove heated oil from the oil space & replace it with with cooled oil.

I am correct, simple as that. Post #81. You are a great example of cannot fix dumb....

The Bosch Handbook I quoted from lists 6 pages of contributing authors, many with 'Dr' in front of their names.

Not sure about Ch, but GM oil pressure safety switches [ warning light ] activate at 3-5 psi. Not 20, not 50 psi. That is because 3-5 psi is all that is reqd to lube the rod/main brgs at idle. The reason higher pressures are used is that the oil carries away heat; that is oil's other function. If the the pressure is insufficient, the oil stays in the brg too long & overheats. The high pressure is not reqd for lubricating, it is reqd to remove heated oil from the oil space & replace it with with cooled oil.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

LOL, I've already previously pointed that out, but feel free to repeat it back to me.the oil carries away heat; that is oil's other function.

Sometimes you need to hear/see it twice to get the message. And no, you made no mention of oil carrying away heat from the rod/main brgs, another lie.

Two different oil delivery systems, according to you. With your vast knowledge, maybe you can elaborate on WHY bearings of any kind would care what delivery system is used to deliver oil, as long as they get oil.

Two different oil delivery systems, according to you. With your vast knowledge, maybe you can elaborate on WHY bearings of any kind would care what delivery system is used to deliver oil, as long as they get oil.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

Oh dearAnd no, you made no mention of oil carrying away heat from the rod/main brgs, another lie.

I pointed out that oil carries the heat away when I was talking about pressurized oil feeds to needle roller lifers earlier on.. So yes, I obviously understand that function of oiling..

See the quote of your post in my previous post above ? It quotes what oil does, it does not mention anything about the rod/ mains. That's why I specifically quoted it that way..Get the drift?

You went off the edge of the map by yourself on that one.

If you bothered to get your head out of your *** and comprehend the posts then:

1. You wouldn't look like a complete twat

2. You wouldn't be making the false claim that I'm a liar.

I'm just pointing out how the oil is being delivered to the bearings, one internally under full mains pressure, one that is not, that's it, nothing else.The picture shows it clearly. I don't care what the bearing thinks, because I'm not specifically talking about that.

Your the one who's waffling on all over the shop with, heat dispersion, wedges etc, accusing people of being liars and generally losing your **** over it..

Time to move on I think..

Last edited:

Waffling on? Your last post has 3-4 times as many lines as mine. With even more nonsense & wrong information.

Move on, you say.....Yes, that is your usual tactic. Make false &/or wrong statements, then when you get caught out.......

Just like the LSA/LDA debate when you got it wrong.

If you are not specifically talking about the brg, then what the hell are you talking about??? Enlighten us. Because I AM & have been talking about the bearing.

[1] So, genius, full mains pressure gets delivered to the rod/main brgs. The bushing in a bushed lifter is getting supplied to it by the same oil supply.

[2] Wedges. Probably above your intellect level. But fundamental in understanding how the brgs in question work.

[3] Using your 'logic', piston pins that get oiled by a groove in the piston would seize up because there is not a drilled oil in the middle of the pin boss suppling mains pressure oil.

Move on, you say.....Yes, that is your usual tactic. Make false &/or wrong statements, then when you get caught out.......

Just like the LSA/LDA debate when you got it wrong.

If you are not specifically talking about the brg, then what the hell are you talking about??? Enlighten us. Because I AM & have been talking about the bearing.

[1] So, genius, full mains pressure gets delivered to the rod/main brgs. The bushing in a bushed lifter is getting supplied to it by the same oil supply.

[2] Wedges. Probably above your intellect level. But fundamental in understanding how the brgs in question work.

[3] Using your 'logic', piston pins that get oiled by a groove in the piston would seize up because there is not a drilled oil in the middle of the pin boss suppling mains pressure oil.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

By the way, here is a cutaway pic of the bush showing the spiral groove that assists drawing the oil in from the outside of the bush.

Of course a main/ rod does not need that groove because the oil is directly delivered internally under mains pressure.

But hey, don't think I'm laughing at you Bewy.. Cos I'm not..

Really I'm not...

I still use LSA and LCA.. lots of cams and no problems so far.. Guess I'm just lucky, but it's nice to know it's still renting space in your head .

.

I have to tell you to move on because :

1.your incapable of doing it yourself..

2. It annoys you..

Move on Bewy, move on..

Of course a main/ rod does not need that groove because the oil is directly delivered internally under mains pressure.

But hey, don't think I'm laughing at you Bewy.. Cos I'm not..

Really I'm not...

I still use LSA and LCA.. lots of cams and no problems so far.. Guess I'm just lucky, but it's nice to know it's still renting space in your head

I have to tell you to move on because :

1.your incapable of doing it yourself..

2. It annoys you..

Move on Bewy, move on..

Last edited:

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

Yeah, lets not get into personal attacks... LOL

Your just too funny..

Move on...

Your just too funny..

You are a great example of cannot fix dumb....

Probably above your intellect level.

another lie.

Move on...

512Stroker

We are all here because we are not all there.

Bewy we have a saying here in the states "Ya can't fix stupid".Yes, & all true. It goes to a new low when you inject family/friends into the thread.

Just hit ignore

Happy motoring

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

Yeah, and you have the saying "Bitches gotta *****".Bewy we have a saying here in the states "Ya can't fix stupid".

Just hit ignore

Happy motoring

Somehow I don't think your evaluation of who "is" and "isn't" stupid around here would be that reliable., because bitches always let their personal feelings get in the way of reality.

But anyway, suggesting Bewy ignore and move on is a good one.

Last edited:

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,311

Yep, just remember who gave you that advice firstYes, good advice from 512. Just ignore idiots like you & move on.

-