REALLY good!!Looking good Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Next Phase of my Mopar Life

- Thread starter BrianT

- Start date

-

The reason I installed the 1/2" offset kit was because I only had 5/16" clearance between the springs and my rear tires.

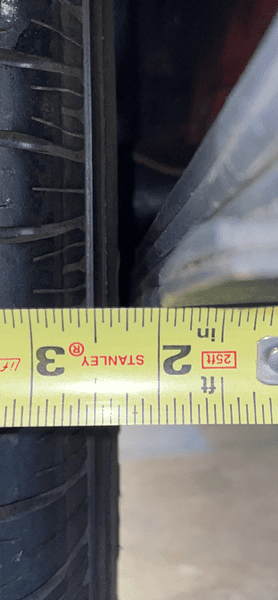

I threw a tape measure on it today, and now I have 1 5/16" clearance?!?!

I had completely forgotten that the 8.25 rear end was one inch narrower than the 8.75. I gained 1/2" clearance from using the new rear end and another 1/2" from the offset spring kit, for a total gain of 1". It also pushed the rear tires out and that's what caught my eye and got me thinking. It's amazing that the human eye can perceive a 1/2" difference and the brain can recognize the change.

I threw a tape measure on it today, and now I have 1 5/16" clearance?!?!

I had completely forgotten that the 8.25 rear end was one inch narrower than the 8.75. I gained 1/2" clearance from using the new rear end and another 1/2" from the offset spring kit, for a total gain of 1". It also pushed the rear tires out and that's what caught my eye and got me thinking. It's amazing that the human eye can perceive a 1/2" difference and the brain can recognize the change.

Time for bigger tires!!!

I plan on keeping these as my "street" tires. They are basically brand new and will be fine driving around this summer. When I go to my "strip" set up, I'll stuff the biggest sticky tire in there that I can.

I was standing around yesterday admiring my work from the previous day and I remembered that I had the trunk light harness off of my old Dart. I don't know why I kept it, but it was one of the small things that I had added and I wanted to have it. Fifteen minutes later it was installed on the Duster.

I just finished my new trunk molding and I was wondering what that flange was for. Now I know, thanks!

Happy Easter everyone! Got a busy weekend so not much getting done to the car, but I did manage to buy and assemble a HF transmission jack. I have been looking for a used one for a while now, but always seem to just miss out on them. I'll use this one once, and then probably list it for sale.

@VOETOM came over this morning and we were able to measure the run out on the bellhousing. It has .032 total run out, divided by two gets us .016. I ordered a set of .014 offset dowels from RobbMcPerformance Bellhousing Alignment Dowels to get the bellhousing back to within specs.

While we were under there Tom muscled the transmission into place so that we could take measurements for the driveshaft I am having built. We knew what length a V8 4 speed with an 8 3/4" should take, but my OCD wouldn't let me have a driveshaft built that might not fit. The measurements came right in at stock specs. I'll swing by the drive train shop next week and get them started on it.

While we were under there Tom muscled the transmission into place so that we could take measurements for the driveshaft I am having built. We knew what length a V8 4 speed with an 8 3/4" should take, but my OCD wouldn't let me have a driveshaft built that might not fit. The measurements came right in at stock specs. I'll swing by the drive train shop next week and get them started on it.

Tom is a great guy. He helped me out big time with the exhaust on my Barracuda!

Measure twice, cut once!

I picked up my driveshaft Friday after work. It's a 3 1/2 inch with 1350 joints built at a local driveline shop. It should stand up to anything that I throw at it.

More progress was made last weekend. VoeTom came over and we installed the offset dowels for the bellhousing. Total run out is now within specs. I replaced the pilot bushing and installed the flywheel, clutch and pressure plate.

We had the spark plugs out to make it easier to rotate, and I noticed that one of them had a cracked porcelain. Luckily I had a set of brand new NGKs on the shelf gathering dust, so I put them in. We had to remove the oil filter adapter to pound out the old dowels so it went back in with all new gaskets and a fresh Wix oil filter.

We had the spark plugs out to make it easier to rotate, and I noticed that one of them had a cracked porcelain. Luckily I had a set of brand new NGKs on the shelf gathering dust, so I put them in. We had to remove the oil filter adapter to pound out the old dowels so it went back in with all new gaskets and a fresh Wix oil filter.

-