I have a member asking about purchasing a set of 273 exhaust manifolds from a 65 Plymouth Signet. This member would be using them on a 318 engine. So, my question is what 318 years can use 273 early a exhaust manifolds? Thanks. Sgrip65

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1965 MOPAR, 273 Exhaust Maifolds

- Thread starter sgrip65

- Start date

-

All if them. 302 heads need the AIR ports plugged.I have a member asking about purchasing a set of 273 exhaust manifolds from a 65 Plymouth Signet. This member would be using them on a 318 engine. So, my question is what 318 years can use 273 early a exhaust manifolds? Thanks. Sgrip65

273 and 318 ports are the same size.

Would you elaborate maybe with a photo302 heads need the AIR ports plugged

Professor Fate

Push the button, Max...

The ports will match up just fine, however-

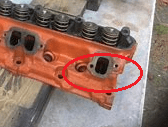

If the heads are '73 ish or earlier, and have this shape pad around the ports, you will be fine.

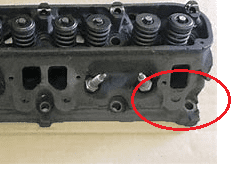

But if you've got '74/'75 ish or later heads with the extended pads (made for air injection, may be drilled or may not, needs to be plugged if it is), like this:

Then there will be interference between the bottom portion of the exhaust pad on #7 and the downleg of the exhaust manifold, which will not allow you to tighten down the manifold to the head.

The amount of interference varies due to manufacturing tolerances, sometimes you can get away by double gasketing the manifold, sometimes you have to use a spacer, normally a header flange, to gain the needed clearance.

Some say that they have been able to grind enough of the offending pad to get it to fit, but I have personally hit the water jacket just under the surface with minimal grinding- up to you if you want to take that chance and trash a head. Even if you don't hit the jacket, how thin is the metal that's left? I play it safe now and just use the spacer.

But as I previously said, if you have the earlier heads, it's no problem.

Edit: Just to clarify, to my knowledge this is only an issue with the (early) A body manifold, and only on the driver's side.

If the heads are '73 ish or earlier, and have this shape pad around the ports, you will be fine.

But if you've got '74/'75 ish or later heads with the extended pads (made for air injection, may be drilled or may not, needs to be plugged if it is), like this:

Then there will be interference between the bottom portion of the exhaust pad on #7 and the downleg of the exhaust manifold, which will not allow you to tighten down the manifold to the head.

The amount of interference varies due to manufacturing tolerances, sometimes you can get away by double gasketing the manifold, sometimes you have to use a spacer, normally a header flange, to gain the needed clearance.

Some say that they have been able to grind enough of the offending pad to get it to fit, but I have personally hit the water jacket just under the surface with minimal grinding- up to you if you want to take that chance and trash a head. Even if you don't hit the jacket, how thin is the metal that's left? I play it safe now and just use the spacer.

But as I previously said, if you have the earlier heads, it's no problem.

Edit: Just to clarify, to my knowledge this is only an issue with the (early) A body manifold, and only on the driver's side.

Last edited:

Professor Fate

Push the button, Max...

The photo I posted above shows the air port just below the exhaust ports. These are a small passage that leads to the exhaust port.Would you elaborate maybe with a photo

You drill them out, tap them and plug them with a 1/4-20 allen screw (use Loctite).

Without the OP knowing exactly what he has and what he is looking at for manifolds, who's to say for sure what he will need to do to make them work. (if anything) We need the application the manifolds are going on, (his car) with the head numbers on that engine, and the numbers on the manifolds.

Well crap.Then there will be interference between the bottom portion of the exhaust pad on #7 and the downleg of the exhaust manifold, which will not allow you to tighten down the manifold to the head

I picked up a cheap 79 318 with low miles (relatively) and planned on using some 68 318 exhaust manifolds.

Professor Fate

Push the button, Max...

Those shouldn't have any issues, it's just with the '66 and earlier manifolds (although it doesn't hurt to check). Just plug the AIR ports and you should be fine with the '68 manifolds.Well crap.

I picked up a cheap 79 318 with low miles (relatively) and planned on using some 68 318 exhaust manifolds.

In a what?Well crap.

I picked up a cheap 79 318 with low miles (relatively) and planned on using some 68 318 exhaust manifolds.

67 dart. ( I'm not the OP by the way)In a what?

I know. Trying to keep 2 questions and conversations straight.67 dart. ( I'm not the OP by the way)

I just used 308 style heads on a 318, tapped and blocked the air ports and installed 68-70 340 manifolds with no sealing issues whatsoever.

In a ?I just used 308 style heads on a 318, tapped and blocked the air ports and installed 68-70 340 manifolds with no sealing issues whatsoever.

1970 Dart - what difference does the body make???

I did not realize the 65 manifold was different than the 67I know. Trying to keep 2 questions and conversations straight

The ports will match up just fine, however-

If the heads are '73 ish or earlier, and have this shape pad around the ports, you will be fine.

View attachment 1716176166

But if you've got '74/'75 ish or later heads with the extended pads (made for air injection, may be drilled or may not, needs to be plugged if it is), like this:

View attachment 1716176169

Then there will be interference between the bottom portion of the exhaust pad on #7 and the downleg of the exhaust manifold, which will not allow you to tighten down the manifold to the head.

The amount of interference varies due to manufacturing tolerances, sometimes you can get away by double gasketing the manifold, sometimes you have to use a spacer, normally a header flange, to gain the needed clearance.

View attachment 1716176173

Some say that they have been able to grind enough of the offending pad to get it to fit, but I have personally hit the water jacket just under the surface with minimal grinding- up to you if you want to take that chance and trash a head. Even if you don't hit the jacket, how thin is the metal that's left? I play it safe now and just use the spacer.

But as I previously said, if you have the earlier heads, it's no problem.

Edit: Just to clarify, to my knowledge this is only an issue with the (early) A body manifold, and only on the driver's side.

It may not matter about the air port plugs with the early style exhaust manifolds.. They may not go that far down for any interference, he would just have to plug the holes to prevent an exhaust link...

The early exhaust manifolds (I believe 64 - 71 series) don't extend down far enough to interfere with the exhaust port on the head where the plug would be... The later model exhaust manifolds do...

I did not realize the 65 manifold was different than the 67

Well crap.

I picked up a cheap 79 318 with low miles (relatively) and planned on using some 68 318 exhaust manifolds.

They should work...

I did not realize the 65 manifold was different than the 67

It may not matter about the air port plugs with the early style exhaust manifolds.. They may not go that far down for any interference, he would just have to plug the holes to prevent an exhaust link...

The early exhaust manifolds (I believe 64 - 71 series) don't extend down far enough to interfere with the exhaust port on the head where the plug would be... The later model exhaust manifolds do...

64 - 66 273 Right side:

64 - 66 273 Left side:

Left side will hit with 64-66 LH or Drivers Side exhaust manifold using 73? up LA heads with the air boss. No problems with 67 up manifolds. Magnum heads have the same small exhaust port and do not have an EGR air port so they should work with the 64-66 exhaust manifold as well.

cudamark

Well-Known Member

Your RH manifold is a '68-70 version. The '64-7 came with the stamped steel heat riser weight and have an earlier casting number 2465769 IIRC.64 - 66 273 Right side:

View attachment 1716176245

View attachment 1716176246

64 - 66 273 Left side:

View attachment 1716176247

View attachment 1716176248

Your RH manifold is a '68-70 version. The '64-7 came with the stamped steel heat riser weight and have an earlier casting number 2465769 IIRC.

I got those off of some internet postings... That was what the listing said, however as we know, some listings may not be correct...

The point I was showing is the ports on the early manifolds do not overlap with the air holes on the later model heads and should seal on those also...

cudamark

Well-Known Member

Correct, the early manifolds do not cover the A.I.R. ports, therefore those ports need to be plugged if using early manifolds on late heads. As mentioned, the LH '64-6 manifold will not bolt down on a late head without spacing the manifold out or grinding the head for clearance at the rear of the head below #7 exhaust port. You'll crack the manifold if you try.I got those off of some internet postings... That was what the listing said, however as we know, some listings may not be correct...

The point I was showing is the ports on the early manifolds do not overlap with the air holes on the later model heads and should seal on those also...

Professor Fate

Push the button, Max...

And this is what happens when you try to tighten it down.As mentioned, the LH '64-6 manifold will not bolt down on a late head without spacing the manifold out or grinding the head for clearance at the rear of the head below #7 exhaust port. You'll crack the manifold if you try.

This came to me because the guy couldn't get rid of a bad exhaust leak, no matter how hard he tightened it down. Hmmm...

To illustrate the point, here is a head with air injection bosses.

I put on the ('64-'66) early A manifold and snugged it down.

The red circle shows the point of interference. The green circle shows the remaining gap between the manifold and the head. That's just shy of 1/4 inch! Even with a gasket, that ain't gonna seal. You could try grinding the boss, but there is a water jacket just under the surface, you don't want to hit it. I have- junk head.

The answer? As I stated above, use a header flange as a spacer (and appropriately longer studs).

Now. the manifold fits like a glove.

Lotsa clearance now. The header flange may need it's edge beveled in some cases, but here it just clears.

Now, someone mentioned bolting these up to Magnum heads. So, just for sh*ts and grins, I test fitted the early A manifolds to a Magnum I have on the stand. Guess what?

The interference isn't as bad, but it's still there, leaving about a 3/16 gap at #7. It seems to be caused mostly by casting flash and a very minor bit of head interference. How you would want to deal with it is up to you, but be aware that it's there.

Last edited:

Could some be taken off the manifold and some off the head to gain clearance?

-