Why won't the cam come out the front??? If it spins freely, gotta be able see why it won't come out?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

273 302 318 340 build

- Thread starter 4spdragtop

- Start date

-

The camshaft bearings are different sizes... They step up, you have to take it out from the front or it will have interference with the other journals if you try to remove it in the opposite direction....

4spdragtop

Well-Known Member

Ok so had dad looking over my shoulder today and had success.

Got cam out the front. Bearing wasnt spun. Just didnt hold my tongue right when pulling it out.

Came out fine looks ok? Some.varnish spots. All bearing oil holes lined up.

Next onto rounded head bolt...of.course it was the middle lower one that is "shrouded" fer frig sakes.

Able to take a grinder to it and hammer a 11/16 wrench onto it and get it out. 2 for 2!!

Heads are 4027163 casting big valve heads.

I will dismantle valves/springs.

Maybe reuse the springs?

Then flipped her onto her belly and took her pan off.

Pan looks brand new, Bonus!

Nothing stands out as being an issue with bottom end.

Im at the.point on the 318 where I dont want to dismantle anymore. Not saying I wont but if I remove pistons or crank them I may as well put new bearings in. Agree/disagree? ? If I do its more $$

So now is clean/inspect and start a list. And do some research lol

I dont think you can enlarge the 302's for larger valves 1.88 and 1.60 cam you? Machinist said not enough meat there? Correct me if we can.

BUT here is the kicker with machining....

$230 to recut/reface valve seats.

$10/hole for valve guides

$65/head to resurface head-block surface.

It can add up quick even if.they come back crack free.

Thanks again guys, bit of a hectic day and not a lot of time to read/comprehend todays replies lol.

Good day tho going 2-2!

Got cam out the front. Bearing wasnt spun. Just didnt hold my tongue right when pulling it out.

Came out fine looks ok? Some.varnish spots. All bearing oil holes lined up.

Next onto rounded head bolt...of.course it was the middle lower one that is "shrouded" fer frig sakes.

Able to take a grinder to it and hammer a 11/16 wrench onto it and get it out. 2 for 2!!

Heads are 4027163 casting big valve heads.

I will dismantle valves/springs.

Maybe reuse the springs?

Then flipped her onto her belly and took her pan off.

Pan looks brand new, Bonus!

Nothing stands out as being an issue with bottom end.

Im at the.point on the 318 where I dont want to dismantle anymore. Not saying I wont but if I remove pistons or crank them I may as well put new bearings in. Agree/disagree? ? If I do its more $$

So now is clean/inspect and start a list. And do some research lol

I dont think you can enlarge the 302's for larger valves 1.88 and 1.60 cam you? Machinist said not enough meat there? Correct me if we can.

BUT here is the kicker with machining....

$230 to recut/reface valve seats.

$10/hole for valve guides

$65/head to resurface head-block surface.

It can add up quick even if.they come back crack free.

Thanks again guys, bit of a hectic day and not a lot of time to read/comprehend todays replies lol.

Good day tho going 2-2!

Last edited:

4spdragtop

Well-Known Member

I plan on cc'ing all the heads as well. I never did cc the factory 273 heads. Also not sure if open or closed chamber?? Considering I did the cleanup/ port job last year you would think I would remember dammit.

Thanks

Steve

Thanks

Steve

4spdragtop

Well-Known Member

I was being.too much of a bear with it. Got it out, thanks

Why won't the cam come out the front??? If it spins freely, gotta be able see why it won't come out?

4spdragtop

Well-Known Member

Approx 1.75 INT and 1.46 EX

Also dbl checked cast iron 340 intake and its a 72.

What size valves are in them?

It may be worth bumping them up to 360 1.88/1.60 inch if they are smaller... Then open up the ports a bit and gasket match them...

Also dbl checked cast iron 340 intake and its a 72.

4spdragtop

Well-Known Member

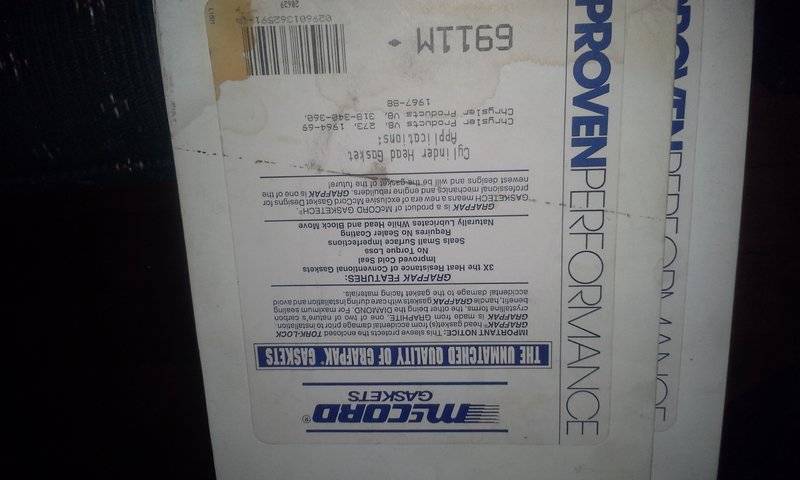

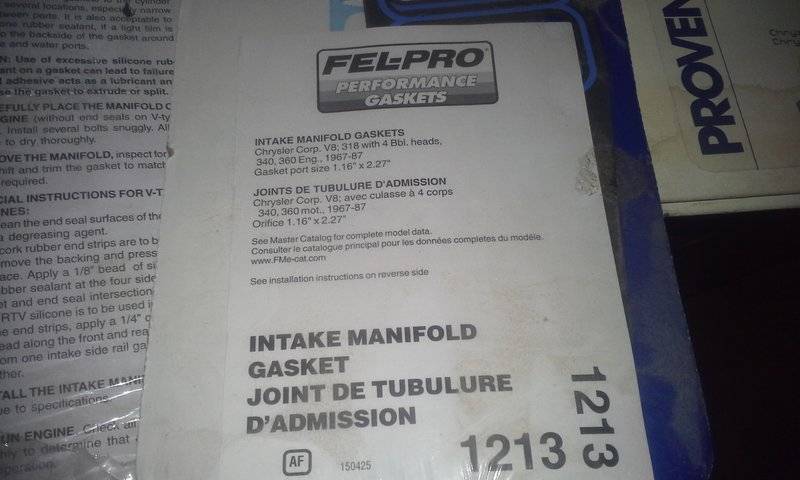

Found an old set of Mccord 6911M head gaskets in the garage. Cant find compressed thickness on the pkg. Also Felpro 1213;intake manifold gasket set. That right there saves me about $100! 3-3 now

I understand all LA head's valves are the same distance apart so they should be able to take larger valves but I think you would be fine with stock. IMO

4spdragtop

Well-Known Member

Good point Lelo thanks. To verify this I should be able to measure center of stem to center of stem on "assembled" heads with different valve sizes correct? Measurement should be the same?

I measured valves still on 4027163 heads and got approx 1.5005" EX and 1.7785 INT

Another set of valves on heads #3671587 gave me approx 1.60" EX and 1.8805" INT

I measured valves still on 4027163 heads and got approx 1.5005" EX and 1.7785 INT

Another set of valves on heads #3671587 gave me approx 1.60" EX and 1.8805" INT

Good point Lelo thanks. To verify this I should be able to measure center of stem to center of stem on "assembled" heads with different valve sizes correct? Measurement should be the same?

I measured valves still on 4027163 heads and got approx 1.5005" EX and 1.7785 INT

Another set of valves on heads #3671587 gave me approx 1.60" EX and 1.8805" INT

1.50 Exh and 1.78 Intake are 318 size valves...

I would look into putting the 587 valves in the 302 head.... Those are the same as a 360...

I plan on cc'ing all the heads as well. I never did cc the factory 273 heads. Also not sure if open or closed chamber?? Considering I did the cleanup/ port job last year you would think I would remember dammit.

Thanks

Steve

Those heads are open chamber in the picture...

I plan on cc'ing all the heads as well. I never did cc the factory 273 heads. Also not sure if open or closed chamber?? Considering I did the cleanup/ port job last year you would think I would remember dammit.

Thanks

Steve

This thread shows how to measure the cc's of your head and engine at home with affordable and accurate method....

How to Check Compression

Ok so had dad looking over my shoulder today and had success.

Got cam out the front. Bearing wasnt spun. Just didnt hold my tongue right when pulling it out.

Came out fine looks ok? Some.varnish spots. All bearing oil holes lined up.

Next onto rounded head bolt...of.course it was the middle lower one that is "shrouded" fer frig sakes.

Able to take a grinder to it and hammer a 11/16 wrench onto it and get it out. 2 for 2!!

Heads are 4027163 casting big valve heads.

I will dismantle valves/springs.

Maybe reuse the springs?

Then flipped her onto her belly and took her pan off.

Pan looks brand new, Bonus!

Nothing stands out as being an issue with bottom end.

Im at the.point on the 318 where I dont want to dismantle anymore. Not saying I wont but if I remove pistons or crank them I may as well put new bearings in. Agree/disagree? ? If I do its more $$

So now is clean/inspect and start a list. And do some research lol

I dont think you can enlarge the 302's for larger valves 1.88 and 1.60 cam you? Machinist said not enough meat there? Correct me if we can.

BUT here is the kicker with machining....

$230 to recut/reface valve seats.

$10/hole for valve guides

$65/head to resurface head-block surface.

It can add up quick even if.they come back crack free.

Thanks again guys, bit of a hectic day and not a lot of time to read/comprehend todays replies lol.

Good day tho going 2-2!

View attachment 1715036786

View attachment 1715036787

View attachment 1715036788

View attachment 1715036789

View attachment 1715036790

View attachment 1715036791

View attachment 1715036792

View attachment 1715036793

View attachment 1715036794

Get a 3" and 4" wire wheel and put it on your drill and clean up the cylinders, piston tops, and head faces and combustion chambers...

If you loosen the rod caps, I would recommend replacing the studs and having them reconditioned for the new studs... If you keep tightening and loosening them, they will get too much stretch...

If you change the bearings, you will have to put two more clamp cycles on them to do it right... One to plastic gauge, and another to final assembly...

If this is a virgin engine and never been apart, you may be able to do it without replacing the rod bolts...

You should only tighten a rod bolt 5 times, then replace them to make sure they don't get too much stretch and will fail/break....

However, a good ring and bearing refresh would do that motor well, and you can get an affordable engine kit for that from Mancini Racing:

Sealed Power Engine Kit - 318

If you're this far into it, go that extra step to make it that much better...

And if you don't have a good double roller timing chain, I would recommend this one, I've used them for years and they will go over 100,000 miles with very minimal stretch....

Edelbrock

nm9stheham

Well-Known Member

I'd throw some sort of bore gauge in each hole and check for any of them being a lot bigger than the others, and look for how much taper and out-of-roundness and wear that you find. If you find .004"-.005" taper or more, it ain't gonna stay sealed up much longer, if it seals at all. I have found individual low compression engine bores worn .020+" and still have the compression check the same as the other cylinders...... oiling up through the rings can fool you big time with just a compression reading. But they won't run evenly that way and will be down on power bit time .....and going up in CR will just make any cylinder issues bigger. You gotta check it all if you are in there.....

Not too much crud underneath. That is good!

BTW< the bearings are 30 years old. Bearing materials start to get brittle and can start flaking off at about that age. I would be pulling the rod and main bearings for sure for sure; you have no way to know if one is flaking out or if is is badly scored and ready to let go. I assume you are going with the 302 heads and that will up the SCR and put more pressure on the bearings. It would be very unwise IMHO to not inspect the bearings at this time. Don't fret over the number of times those rod bolts have been used; these likely are 'virgin'.

Inspect the cam bearings (with a mirror for the bottom side) and if no flaking is seen, then maybe keep them in if you want to save the $$; they are a lot more forgiving than rod or main bearings. (But they can flake off too.)

How about pull the McCord head gaskets out of the box and look at them? Put a caliper on them to see if they are thick, like .050" or more. If you are lucky, these will be stock shim gaskets. I'll be straight-up with you: I think it is penny foolish to use thick head gaskets and expecting this engine to be a lot better for torque. The originals were shim gaskets around .022 thick; going with .050" thick head gaskets is just one more torque killer. Even with a smaller cam, you still need to fight for CR with those low CR pistons. 1121G gaskets are only $23 each; they ain't Cometics at $105 each!

Yeah, head work is not cheap, doggone it. But it is one of the 2 big keys to a solid running engine. (Good cylinder bores and rings and pistons being the other big key.)

Not too much crud underneath. That is good!

BTW< the bearings are 30 years old. Bearing materials start to get brittle and can start flaking off at about that age. I would be pulling the rod and main bearings for sure for sure; you have no way to know if one is flaking out or if is is badly scored and ready to let go. I assume you are going with the 302 heads and that will up the SCR and put more pressure on the bearings. It would be very unwise IMHO to not inspect the bearings at this time. Don't fret over the number of times those rod bolts have been used; these likely are 'virgin'.

Inspect the cam bearings (with a mirror for the bottom side) and if no flaking is seen, then maybe keep them in if you want to save the $$; they are a lot more forgiving than rod or main bearings. (But they can flake off too.)

How about pull the McCord head gaskets out of the box and look at them? Put a caliper on them to see if they are thick, like .050" or more. If you are lucky, these will be stock shim gaskets. I'll be straight-up with you: I think it is penny foolish to use thick head gaskets and expecting this engine to be a lot better for torque. The originals were shim gaskets around .022 thick; going with .050" thick head gaskets is just one more torque killer. Even with a smaller cam, you still need to fight for CR with those low CR pistons. 1121G gaskets are only $23 each; they ain't Cometics at $105 each!

Yeah, head work is not cheap, doggone it. But it is one of the 2 big keys to a solid running engine. (Good cylinder bores and rings and pistons being the other big key.)

4spdragtop

Well-Known Member

So my little helper Lennon dropped by. She saw me trying to clean up the block. "Me fix" she said. I handed her the glasses and drill. She enjoyed it for 5 minutes. Lol

4spdragtop

Well-Known Member

So still undecided which way to go, but no matter what it needs a good clean. Tapping/cleaning all holes. Using lard on the tap, cheaper then drill/tap oil and supposed to work just as good.

Date code 06/83 I think

Vin # X517595 (hard to make out)

Oil pump will be coming off for inspection. In the meantime cleaning until I hear from shop on 302 heads

I have am 1984 truck FSM. I believe I should be good to use torque specs from it for the most part? As mentioned block is an 06-83 date code I believe.

Thanks again all for advice I appreciate and believe it or not some is sinking in.

Date code 06/83 I think

Vin # X517595 (hard to make out)

Oil pump will be coming off for inspection. In the meantime cleaning until I hear from shop on 302 heads

I have am 1984 truck FSM. I believe I should be good to use torque specs from it for the most part? As mentioned block is an 06-83 date code I believe.

Thanks again all for advice I appreciate and believe it or not some is sinking in.

nm9stheham

Well-Known Member

Good on the FSM; just remember the torque spec of 30 ft lbs for the rocker shaft bolts is wrong....18-20 ft lbs max. I like your helper... some guys get all the luck.... pretty dames showing up in their shop ... and working on car stuff! LOL

How does it get better than that!

So my little helper Lennon dropped by. She saw me trying to clean up the block. "Me fix" she said. I handed her the glasses and drill. She enjoyed it for 5 minutes. Lol

View attachment 1715037490

View attachment 1715037491

mullinax95

Well-Known Member

I vote 318 with 302 heads (milled down to bump up compression) with the 273 adjustable valve train. Don't forget to plug the smog ports on the 302 heads.

rigger3006

Well-Known Member

when i had my 302s at machine shop the builder installed 1.60 ex valves, but said id be wasting my money putting in 188s for intake. ive read that same info in a few different writeups.

Not saying to do it but the valves will work. All the rockers are the same except race stuff.

Shady Dell Speed Shop

Shady Dell Speed Shop

Last edited:

So my little helper Lennon dropped by. She saw me trying to clean up the block. "Me fix" she said. I handed her the glasses and drill. She enjoyed it for 5 minutes. Lol

View attachment 1715037490

View attachment 1715037491

Start them while they are young...

I did that with my kids...

I vote 318 with 302 heads (milled down to bump up compression) with the 273 adjustable valve train. Don't forget to plug the smog ports on the 302 heads.

Hi Mully, haven't heard from you in a while...

Good to see you're back....

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,611

- Reaction score

- 13,844

As to your Scr, I agree with Nm9 and others,

The 318 for street and fuel economy,needs a compression boost. I would urge you to put some much taller pistons in there.At $65 per head for machining, and maybe another $65 to fit the intake to the new head height, you already have a good chunk of a new set of pistons/rings.

I gotta tell you at 120psi, that teener is not much of a puller.Putting a cam in it will only make it worse. It will need a 2800TC minimum to get moving, and wants a starter gear up near 10 or 11 to accelerate briskly. And the whole reason for this is cuz at 120 psi the teener is lazy as all get out in the torque making business, and so it has to be bandaided for street duty. So by the time you add the cost of a new TC and 3.91/4.10s, you are way beyond what you need, to get the compression up, with pistons. With compression up closer to 150/160, that teener will have a whole new personality. You will be able to do a lot more with a lot less cam. Less cam means less TC and less gear required. If the 3.23s are staying, then you need pressure if you want performance at zero to 30mph.

But keep in mind building psi is a joint venture with compression and the intake valve closing event.So you have to manipulate them both to arrive at a satisfactory conclusion.

For a streeter,a 268* might sound good at idle, but IMO is not the right cam for most guys. We hear it here all the time where guys just want to sound fast. So they slam a 268 in there and then the stock teener blows them off to nearly 30 mph. Why is that? Cuz the stocker makes 135/140ish pressure and the 268* is down at 110 or less. They skipped the pistons, and now it's back to the drawing board.

So again I urge you to reconsider boosting the compression, and selecting a conservative cam that will maximize your Dcr for the available fuel. And another thing about that is to keep in mind that you only need just enough octane to suppress detonation and no more. It would be entirely feasible to pump up the psi for 91 when using the secondaries, and then run 87 while cruising the hiways, on the transfers.

If you get this right, those extra psi will save you money on every mile it cruises. If you burn a half a tank of 91 on the weekend to satisfy 160psi,and then burn thru another half a tank of 87 going back and forth all week,figure it out. Then compare the cost of that to the the same deal on 120psi but with now running 87 full time, and getting a buncha less mpgs. Oh and a buncha less torque,power

Those pistons are getting cheaper with every mile that car burns gas.

I just can't stress this enough.

The 318 for street and fuel economy,needs a compression boost. I would urge you to put some much taller pistons in there.At $65 per head for machining, and maybe another $65 to fit the intake to the new head height, you already have a good chunk of a new set of pistons/rings.

I gotta tell you at 120psi, that teener is not much of a puller.Putting a cam in it will only make it worse. It will need a 2800TC minimum to get moving, and wants a starter gear up near 10 or 11 to accelerate briskly. And the whole reason for this is cuz at 120 psi the teener is lazy as all get out in the torque making business, and so it has to be bandaided for street duty. So by the time you add the cost of a new TC and 3.91/4.10s, you are way beyond what you need, to get the compression up, with pistons. With compression up closer to 150/160, that teener will have a whole new personality. You will be able to do a lot more with a lot less cam. Less cam means less TC and less gear required. If the 3.23s are staying, then you need pressure if you want performance at zero to 30mph.

But keep in mind building psi is a joint venture with compression and the intake valve closing event.So you have to manipulate them both to arrive at a satisfactory conclusion.

For a streeter,a 268* might sound good at idle, but IMO is not the right cam for most guys. We hear it here all the time where guys just want to sound fast. So they slam a 268 in there and then the stock teener blows them off to nearly 30 mph. Why is that? Cuz the stocker makes 135/140ish pressure and the 268* is down at 110 or less. They skipped the pistons, and now it's back to the drawing board.

So again I urge you to reconsider boosting the compression, and selecting a conservative cam that will maximize your Dcr for the available fuel. And another thing about that is to keep in mind that you only need just enough octane to suppress detonation and no more. It would be entirely feasible to pump up the psi for 91 when using the secondaries, and then run 87 while cruising the hiways, on the transfers.

If you get this right, those extra psi will save you money on every mile it cruises. If you burn a half a tank of 91 on the weekend to satisfy 160psi,and then burn thru another half a tank of 87 going back and forth all week,figure it out. Then compare the cost of that to the the same deal on 120psi but with now running 87 full time, and getting a buncha less mpgs. Oh and a buncha less torque,power

Those pistons are getting cheaper with every mile that car burns gas.

I just can't stress this enough.

4spdragtop

Well-Known Member

Thanks again all for the responses Decision time, I can get a pair of heads.

Scenario A

Price with valve job and a cleanup on the surdace. $560.

I have a set of valves for one head in good shape. PLUS I have 3 used sets from other 3 heads. Which I hope would be enuf to come up with a set for 2nd head. Above valves are all stock 1.78 int and 1.50 ex.

OR

Scenario B

Purchase heads and valve job (same $$ $560)

I get them to cut valves bigger 1.8805 Intake and 1.60 Ex. Price for valve job would be pretty much the same $230/pr. BUT I have a good pr of dressed heads casting #3671587 that have 1.88 INT and 1.60 EX.

So is it worthwhile to go bigger valves with the stock bottom end? Im thinking no. But im open to suggestions.

$560 plus a cam puchase I am now into the $1000 range. Without even touching the pistons.

SCENARIO C.

Invest in Commando pistons for 273??

Kanter has the commando pistons a little over $420 US= $600 Can (approx) shipped.

I removed oil pump. Krazykuda did a diy on the oil pump so I'll check that out...and ponder the budget lol

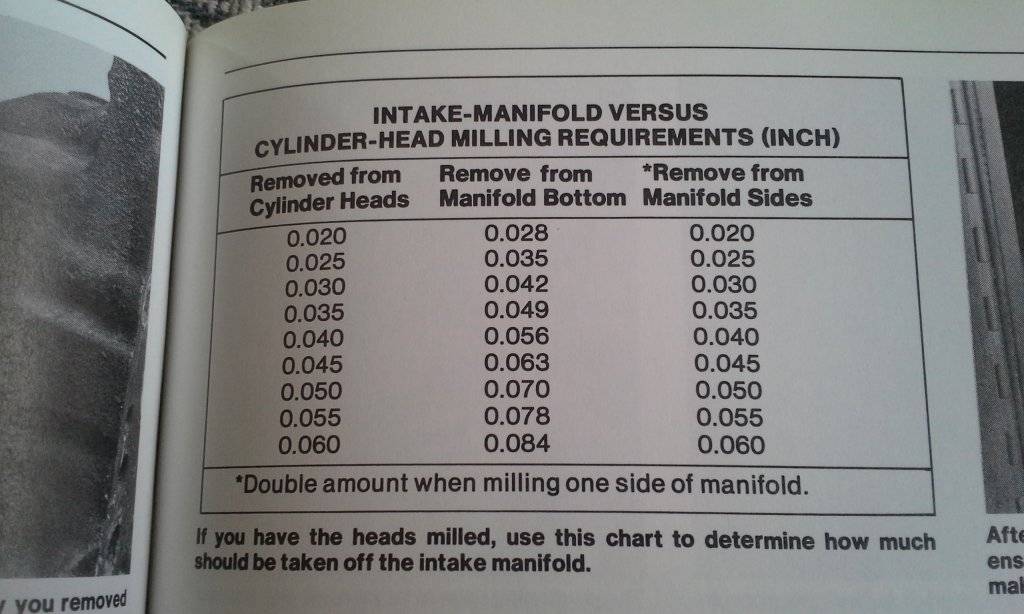

Also here is chart from a mopar sb engine book that shows the machining tolerances on heads compared to intake.

Chart shows it starting at .020" Can I then assume head could be milled 0.015" (assume safely) without needing to machine intake?

Thanks again all.

Scenario A

Price with valve job and a cleanup on the surdace. $560.

I have a set of valves for one head in good shape. PLUS I have 3 used sets from other 3 heads. Which I hope would be enuf to come up with a set for 2nd head. Above valves are all stock 1.78 int and 1.50 ex.

OR

Scenario B

Purchase heads and valve job (same $$ $560)

I get them to cut valves bigger 1.8805 Intake and 1.60 Ex. Price for valve job would be pretty much the same $230/pr. BUT I have a good pr of dressed heads casting #3671587 that have 1.88 INT and 1.60 EX.

So is it worthwhile to go bigger valves with the stock bottom end? Im thinking no. But im open to suggestions.

$560 plus a cam puchase I am now into the $1000 range. Without even touching the pistons.

SCENARIO C.

Invest in Commando pistons for 273??

Kanter has the commando pistons a little over $420 US= $600 Can (approx) shipped.

I removed oil pump. Krazykuda did a diy on the oil pump so I'll check that out...and ponder the budget lol

Also here is chart from a mopar sb engine book that shows the machining tolerances on heads compared to intake.

Chart shows it starting at .020" Can I then assume head could be milled 0.015" (assume safely) without needing to machine intake?

Thanks again all.

Last edited:

-