Couldn’t find his post so I’ll stick under yours if you don’t mind, anyway buy a SRT or Scat Pac my SRT gets 25 mpg hyShould be doable without all the "theory". Main thing will be the carb, exhaust and ignition. Assuming both have a 2.45 rear, the first is a a good ignition. I run Taylor Spiro Core wires, platinum spark plugs, new cap, and new rotor. Convert to Chrysler electronic if you have any ignition problems. Play with timing to run as much advanced as the engine will allow. The best carbs for mpg are the 73?-75? BBD Carter with the adjustable rod hanger, Thermo-Quad, and the Quadra-Jet (318 and 360 trucks and vans). We could get 25 mpg with a factory 75 Cordoba 318 BBD and have gotten the same or better with the Thermo-quad. A good Quadra-Jet should be close to the Thermo-Quad. Use a Performance or Vacuum gage.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

318 MAX fuel economy builds?

- Thread starter gagembassett

- Start date

-

Its all about vaporization which leads to combustion efficiency which leads to increased mileage. If you don't vaporize the mixture you don't burn it. More importantly improved vaporization leads to improved homogenization with increases the detonation resistance. If you do that you can run more compression.......Hmmm wonder what that might do for mileage.

Its not a theory its how it works.....

No Duh. No one needs to know how it works. It's how to do it. What have you done and what are the numbers? I don't sit around and think about what might be.

I do not mind. My 2009 Challenger R/T 6 speed gets 28 mpg at 75 mph and my wifes Charger R/T auto gets 30 + at the same speed. We travel cross country alotCouldn’t find his post so I’ll stick under yours if you don’t mind, anyway buy a SRT or Scat Pac my SRT gets 25 mpg hy

No, this is something you set up on older rides. Computers have knock sensors.Is there a stand alone spark control aftermarket unit for these engines? Something that advances spark just below ping?

Not new, check eBay for Jacob’s ignitions.I remember 30 years ago Jacobs energy team made something. Are they still available?

IMO, exhaust heat is just not consistent enough to use to aid in vaporization. Coolant (heated coolant) would be much more consistent, although you wouldn’t get much help from it on cold starts until the engine temp came up.

Why not both?

The factory used both. EGR holes in the intake floor are opened up with a high vacuum. (I don’t remember what I tested the egr valve open up at, but it does close under a WOT condition.)

So the exhaust will heat up the floor of the intake first and the entire intake track very quickly. During warm up time.

Of course coolant temp takes longer and is more controllable than the egr gasses.

It works but only so fast and so well.

You yourself will have to be on point on this. Also, speaking from experience on this mileage hunt, and not a whole lot of it but when I was hunting for a as much as I could get and the ability to pass the tail pipe test, you can set it up really well for the time your doing it and have it fall off from target pretty badly in six months.

As mentioned and forgive the dead horse beating here, but truly the bottom line is the proper size carb for the job at hand that should be kept cool and have a reasonable primary size to allow a good cruise power without struggle. The fuel from leaving the bowl starts its journey into being mixed with the air. It starts there. Then through and out the booster. This path IMO, should have the fuel well mixed with the air and for throttle and mileage purposes, should leave a annular booster.

Once you find a good mix of air and fuel leaving the carb, the intake is the next part of the travel path that can bennifkt from a certain amount of heat. This is where the coolant temp will come into play.

After that, a multi spark ignition. Then pay attention to the spark plug gap and the ring left behind on the plug. Plug reading and style of plug as well as manufacturer will all come into play. This will be part of the experiment.

Open up the plug as much as practicable.

Many years ago N.Y. State had vehicles tested on a set of dyno like rollers the rear wheels would sit on and the car needed to come up to speed (55mph) and have the exhaust read. I had to run a catalyst and since I had dual exhaust…. Yup! I ran two cats. I grabbed a set of high flow cats from Summit.

Ran great, ran as clean as a newer car, still got 20 mpg’s.

Not awesome mileage, but not to darn bad from the kid tuner 30 years ago.

Last edited by a moderator:

I could do all of that while running an egr manifold and heat the mixture from the top and the bottom.No, this is something you set up on older rides. Commuters have knock sensors.

Not new, check eBay for Jacob’s ignitions.

The factory used both. EGR holes in the intake floor are opened up with a high vacuum. (I don’t remember what I tested the egr valve open up at, but it does close under a WOT condition.)

So the exhaust will heat up the floor of the intake first and the entire intake track very quickly. During warm up time.

Of course coolant temp takes longer and is more controllable than the egr gasses.

It works but only so fast and so well.

You yourself will have to be on point on this. Also, speaking from experience on this mileage hunt, and not a whole lot of it but when I was hunting for a as much as I could get and the ability to pass the tail pipe test, you can set it up really well for the time your doing it and have it fall off from target pretty badly in six months.

As mentioned and forgive the dead horse beating here, but truly the bottom line is the proper size carb for the job at hand that should be kept cool and have a reasonable primary size to allow a good cruise power without struggle. The fuel from leaving the bowl starts its journey into being mixed with the air. It starts there. Then through and out the booster. This path IMO, should have the fuel well mixed with the air and for throttle and mileage purposes, should leave a annular booster.

Once you find a good mix of air and fuel leaving the carb, the intake is the next part of the travel path that can bennifkt from a certain amount of heat. This is where the coolant temp will come into play.

After that, a multi spark ignition. Then pay attention to the spark plug gap and the ring left behind on the plug. Plug reading and style of plug as well as manufacturer will all come into play. This will be part of the experiment.

Open up the plug as much as practicable.

Many years ago N.Y. State had vehicles tested on a set of dyno like rollers the rear wheels would sit on and the car needed to come up to speed (55mph) and have the exhaust read. I had to run a catalyst and since I had dual exhaust…. Yup! I ran two cats. I grabbed a set of high flow cats from Summit.

Ran great, ran as clean as a newer car, still got 20 mpg’s.

Not awesome mileage, but not to darn bad from the kid tuner 30 years ago.

"This path IMO, should have the fuel well mixed with the air and for throttle and mileage purposes, should leave a annular booster."

I have this carb. It's the 1916 not the 1906. Both have annular discharge and the 1916 is billed as superior and close to FI as you can get.

Edelbrock's AVS2 Off-Road Carburetor #1916 with Electric Choke is a special 650 CFM version of the proven #1906 street carb with Annular Flow Booster technology for near-EFI-like drivability that you can feel as soon as you step on the gas.

This carb has an improved annular discharge. See a youtube video of the carb when running. You can see the fuel being metered through 8 metering holes around the inside of the venturi secondary. I figured this would be a great start. It has the same primary as the 500 version and I already have it.

Has anyone else used these carbs?

I have this carb. It's the 1916 not the 1906. Both have annular discharge and the 1916 is billed as superior and close to FI as you can get.

Edelbrock's AVS2 Off-Road Carburetor #1916 with Electric Choke is a special 650 CFM version of the proven #1906 street carb with Annular Flow Booster technology for near-EFI-like drivability that you can feel as soon as you step on the gas.

This carb has an improved annular discharge. See a youtube video of the carb when running. You can see the fuel being metered through 8 metering holes around the inside of the venturi secondary. I figured this would be a great start. It has the same primary as the 500 version and I already have it.

Has anyone else used these carbs?

I used a 650 AVS II electric choke on a 360 for a little while. It worked very well. No complaints.

If you take your time with any carb (IMHO) you should be able to get darn super close to a FI system. Trouble is, most people won’t take the time to size the carb and jet it as well as mess around with the ignition system over and over again to get there set up to the pinnacle of what is possible.

If you take your time with any carb (IMHO) you should be able to get darn super close to a FI system. Trouble is, most people won’t take the time to size the carb and jet it as well as mess around with the ignition system over and over again to get there set up to the pinnacle of what is possible.

omahamoparguy

Well-Known Member

- Joined

- Feb 19, 2010

- Messages

- 756

- Reaction score

- 32

Along time ago, I pulled a 318 out of a 67 belvedere, it had a factory single plane and a 2 barrel Stromberg carb. I shoved it in my 72 Demon complete with 727 Trans. Rear was 8 34 with 2.94 gears. Engine was real loose worn. Tuned it as best as I could, points you know.Decided to move to NJ from FL so ripped out the back seat to have room for all my tools. Stuffed entire car with tools and stuff .til I could barely fit inside. Estimate 1000 lbs easy. Started on trip, thought the fuel sender might have given up the ghost cause it wasn't moving. Pulled in for. Fuel and was shocked. I was averaging 24 mpg. Of course is was only going about 60 to 65 and with the sea level air and cool night time Temps probably contributed to the mpgs. But still thought that was pretty darn good. Of course it was 1987 so better fuel quality? Alway got in the twenty plus mpgs and I had a heavy foot in those days.

A big factor in highway cruising/fuel economy is aerodynamic drag & car shape. The increase in drag is not linear, it is exponential. I found with the brick shaped cars I have owned over the years that good economy ws achieved if you kept the speed down to around 50-55 mph. Once you got to 60 & above, you used more fuel.

James Clews

Well-Known Member

Back in the seventies I had an Ex police 265 hemi six Valiant charger. I put a pacer factory 4 barrel manifold on it and factory headers. Those factory 4 barrel manifolds were very long runner manifolds with a water heated plenum in them. This car ran 14.7 sec qtrs @92 mph . The camshaft and exhaust system were standard police spec. Carb was a vac secondary holley 600 cfm.

This car ran exactly the same as the original 2 barrel and fuel economy was as good if not better than the 2 barrel. The only thing I changed when taking it to the track was to disconnect the water heating and going up 2 sizes in jets.

Until I put the water heating back on after the drag racing it would have a slight dead spot off idle but the water heating fixed that.

This car ran exactly the same as the original 2 barrel and fuel economy was as good if not better than the 2 barrel. The only thing I changed when taking it to the track was to disconnect the water heating and going up 2 sizes in jets.

Until I put the water heating back on after the drag racing it would have a slight dead spot off idle but the water heating fixed that.

Rat Bastid

Dunamis Metron

Back in the seventies I had an Ex police 265 hemi six Valiant charger. I put a pacer factory 4 barrel manifold on it and factory headers. Those factory 4 barrel manifolds were very long runner manifolds with a water heated plenum in them. This car ran 14.7 sec qtrs @92 mph . The camshaft and exhaust system were standard police spec. Carb was a vac secondary holley 600 cfm.

This car ran exactly the same as the original 2 barrel and fuel economy was as good if not better than the 2 barrel. The only thing I changed when taking it to the track was to disconnect the water heating and going up 2 sizes in jets.

Until I put the water heating back on after the drag racing it would have a slight dead spot off idle but the water heating fixed that.

That’s interesting and not surprising. If you can’t get all the fuel vaporized in time you can certainly get a lean spot in the fuel curve.

It’s also interesting to note that there is always a puddle in the bottom of the intake manifold and that’s what fuel the engine runs on.

When manifold vacuum goes to zero (or close to it) the pressure change takes the atomized/vaporized fuel and converts it back to a liquid.

SuperFlow says it takes about 100 engine cycles to recover from that.

EDIT: BTW, was it any quicker/faster with the water not heating the intake??

James Clews

Well-Known Member

Rat Bastid! I never drag raced it with the heating connected but did notice when I disconected the heating I had to increase the jet size, or more importantly with the water heating I could decrease the jet size!

Rat Bastid

Dunamis Metron

Rat Bastid! I never drag raced it with the heating connected but did notice when I disconected the heating I had to increase the jet size, or more importantly with the water heating I could decrease the jet size!

Makes perfect sense to me. Thanks

- Joined

- Dec 31, 2005

- Messages

- 6,865

- Reaction score

- 4,314

Rat Bastid! I never drag raced it with the heating connected but did notice when I disconected the heating I had to increase the jet size, or more importantly with the water heating I could decrease the jet size!

Possibly because it needed more of the lighter fractions that vaporize at lower temps to make up for the fact that you were not vaporizing the heavier ones due to lower temps in the manifold.

Just a thought for those who may possibly want to understand the why's.......

I’m gonna have to call no way..nobody and I mean nobody moves back to Jersey from FloridaAlong time ago, I pulled a 318 out of a 67 belvedere, it had a factory single plane and a 2 barrel Stromberg carb. I shoved it in my 72 Demon complete with 727 Trans. Rear was 8 34 with 2.94 gears. Engine was real loose worn. Tuned it as best as I could, points you know.Decided to move to NJ from FL so ripped out the back seat to have room for all my tools. Stuffed entire car with tools and stuff .til I could barely fit inside. Estimate 1000 lbs easy. Started on trip, thought the fuel sender might have given up the ghost cause it wasn't moving. Pulled in for. Fuel and was shocked. I was averaging 24 mpg. Of course is was only going about 60 to 65 and with the sea level air and cool night time Temps probably contributed to the mpgs. But still thought that was pretty darn good. Of course it was 1987 so better fuel quality? Alway got in the twenty plus mpgs and I had a heavy foot in those days.

Along time ago, I pulled a 318 out of a 67 belvedere, it had a factory single plane and a 2 barrel Stromberg carb. I shoved it in my 72 Demon complete with 727 Trans. Rear was 8 34 with 2.94 gears. Engine was real loose worn. Tuned it as best as I could, points you know.Decided to move to NJ from FL

Holy reversal Batman!I’m gonna have to call no way..nobody and I mean nobody moves back to Jersey from Florida

The exhaust heat will come on almost immediately (only as long as it takes to heat soak the aluminum spacer), which will allow a faster warm-up schedule. You can turn the choke spring back (less tension). I did an experiment with my '95 Jeep GC. It was about 32 degrees out (0 C). I fired the engine, and the injector pulse-width (IPW) went to around 30 milliseconds. After about 10 minutes it was down around 8 ms. Fully warmed up it's a tick over 2 milliseconds.So I'm learning on the fly here and I don't have an opinion as to which of you is correct or even if you are on the same paragraph of the same page.

But I have an idea about using both water and exhaust. I use Air-Aid 1" 4 hole spacer with threads. I'm taking it to the shop as soon as it gets here to have the perimeter center drilled 3/8" and tapped to run water through. I'm also taking a 1" 4 hole spacer with smooth ports that have the lines in the ports to catch the fuel as the book recommends. I'm taking the second spacer to the machine shop to have it drilled and tapped and I'm going to tap the heat cross overs on the manifold and run them through that spacer.

It will go like this. Manifold, Thin square hole gasket, 1" 4 hole regular spacer with scoured ports and exhaust going through it, 1/4" 4 hole insulated gasket, Air-Aid 4 hole spacer with water through it, 1/4" 4 hole insulated gasket, Carb.

The carb remains cooled enough by the coolant plate and thermo spacer, the fuel come from the carb and is thrown against the sides by the vortec. the threads act as fins and have more contact point for heat transfer. As this fuel spins down it comes into the spacer with exhaust in it and it's hotter. The fuel is tossed against the sides and falls into the groves which are super heated by the exhaust but below what I researched to be an issue. Thus creating a hotter and hotter mixture as it drops and the port wall conditions are there to take advantage of it.

Thoughts?

The heat from the exhaust will come on fast but it will not over heat the carb as the insulated gaskets and water in the top plate will dissipate the heat.

I been working on this idea and am in the process of building this and testing it out.

Thoughts?

With the factory ECM control, the engine consumed almost 15X more fuel cold than warmed up! Fuel delivery is increased to compensate for a cold engine that cannot vaporize much fuel -- by a multiplication factor. This means climbing out our hole (steep driveway) with a cold engine chugs fuel. The faster you can turn the choke off, the better short-trip fuel economy will be.

How can I fool the PCM (Warmed up mode) on a Magnum engine?The exhaust heat will come on almost immediately (only as long as it takes to heat soak the aluminum spacer), which will allow a faster warm-up schedule. You can turn the choke spring back (less tension). I did an experiment with my '95 Jeep GC. It was about 32 degrees out (0 C). I fired the engine, and the injector pulse-width (IPW) went to around 30 milliseconds. After about 10 minutes it was down around 8 ms. Fully warmed up it's a tick over 2 milliseconds.

With the factory ECM control, the engine consumed almost 15X more fuel cold than warmed up! Fuel delivery is increased to compensate for a cold engine that cannot vaporize much fuel -- by a multiplication factor. This means climbing out our hole (steep driveway) with a cold engine chugs fuel. The faster you can turn the choke off, the better short-trip fuel economy will be.

I developed an electronic circuit I called the IATimer that starts out

"not there", then gradually ramps in (adjustable ramp time and final offset value) to an offset of the IAT Sensor value for advanced/retarded ignition timing. A similar ramp circuit could expedite the ramp-in of the coolant temp. This version definitely requires electronics & programming skills. Not sure how to do it with junk yard parts, though. I'll give it some thought.

"not there", then gradually ramps in (adjustable ramp time and final offset value) to an offset of the IAT Sensor value for advanced/retarded ignition timing. A similar ramp circuit could expedite the ramp-in of the coolant temp. This version definitely requires electronics & programming skills. Not sure how to do it with junk yard parts, though. I'll give it some thought.

- Joined

- Dec 31, 2005

- Messages

- 6,865

- Reaction score

- 4,314

What do you use?This version definitely requires electronics & programming skills.

My own custom electronics! I can make quick test circuits on generic proto boards, which may last a week or 20 years. Something in the category of "reliable" requires automotive grade components (which are in short supply right now) and a professionally made PCB board (which I get done all the time, but they cost a lot of money in small batches). I use PIC MCU's exclusively, and the MPLABX IDE for programming them.

I’m not smart in electronics but was thinking in the same line but for the o2 sensors, showing it’s already in the warmed up loop. But I can see the temp sensor needs what you say too. My foot can keep it running till it’s really warm.I developed an electronic circuit I called the IATimer that starts out

"not there", then gradually ramps in (adjustable ramp time and final offset value) to an offset of the IAT Sensor value for advanced/retarded ignition timing. A similar ramp circuit could expedite the ramp-in of the coolant temp. This version definitely requires electronics & programming skills. Not sure how to do it with junk yard parts, though. I'll give it some thought.

Last night when I posted, I was dileriously tired -- I taught a Fuel Efficiency Class this weekend. When I recommended turning the choke spring back, it was because something was improved that justified that action. If you have a stock vehicle, the stock tune is about as good as it's going to get (just ask any Federal judge). Accelerating the warm-up ramp will cause a stumble or even stall, and more importantly from a legal standpoint, higher emissions. Changes to factory settings should be used to compensate for other changes. With that said, if you have a more powerful ignition (Pulstar Plugs, Peaking Caps, PDI, etc) or fuel heater not tied to engine coolant or intake air heater for example, then accelerating the warm-up ramp-in would be justified.

The coolant temp sensor (CTS) is a variable resistor -- like a radio volume knob of yore -- where a change of temperature changes the knob setting. There are charts online that show what the resistance should be at different temperatures for most popular engines. Every CTS I've seen has high resistance when cold, and low resistance when hot. Therefore, if you want to show a hotter temperature, you would have to add resistance in parallel to the sensor, reducing overall resistance. To show colder temperatures, add resistance in series in either of the 2 wires. I use the resistance value at 68 degrees F. for the base value.

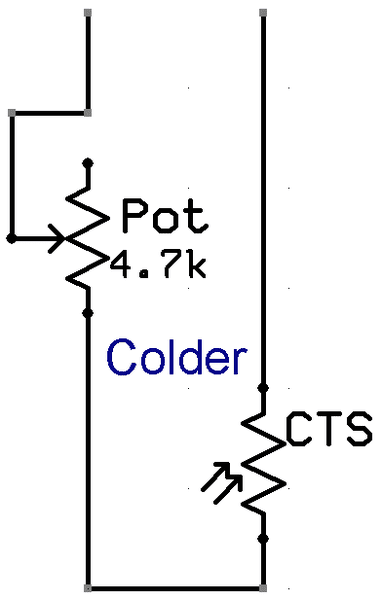

A quick internet search suggests a value of 2k - 3k ohms at 68 for a '98 Magnum engine. Usually the resistance ranges on both the CTS and IAT sensors are pretty close. So, if you wanted to show colder air, you would add resistance in series. Using the 2500 ohm average resistance value, we want a potentiometer with a value slightly higher than that. Cheap pots will be 2.2k, 2.7k, 3.3k, 3.9k, or 4.7k ohms in that range. I'd go for the 4.7k ohms for a bit more range. Cut one of the sensor wires and splice the pot center tap to one of the wires, and either of the 2 outer taps to the other end of the cut. Watch your Scan Tool and turn the knob slowly to see which direction increases the effect. Higher resistance will show cooler temps.

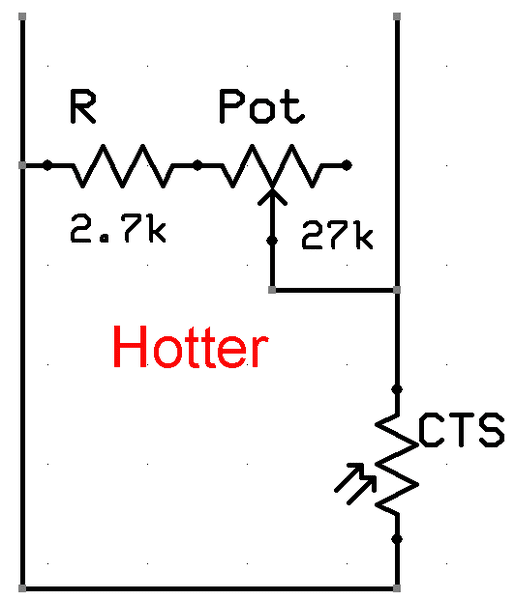

To show hotter air or engine temp, you need to splice a pot in parallel. However, here you want a value around 10X the base value. Remember, the rating of the pot is its MAX value. Turning the knob will reduce resistance where eventually it acts as a short. For this reason, you would want the pot rated at least at 10X the base PLUS a current limiting resistor rated about base value. Let's put this together: 2.7k limiting resistor (1/4 watt 20% tolerance is just fine) and a 27k pot (again, low wattage value OK). The 2.7k resistor is soldered to one of the outer legs on one end, and one of the 2 sensor wires on the other end. The center tap of the pot is soldered to the other sensor wire. Here, lower resistance will show hotter temps.

The coolant temp sensor (CTS) is a variable resistor -- like a radio volume knob of yore -- where a change of temperature changes the knob setting. There are charts online that show what the resistance should be at different temperatures for most popular engines. Every CTS I've seen has high resistance when cold, and low resistance when hot. Therefore, if you want to show a hotter temperature, you would have to add resistance in parallel to the sensor, reducing overall resistance. To show colder temperatures, add resistance in series in either of the 2 wires. I use the resistance value at 68 degrees F. for the base value.

A quick internet search suggests a value of 2k - 3k ohms at 68 for a '98 Magnum engine. Usually the resistance ranges on both the CTS and IAT sensors are pretty close. So, if you wanted to show colder air, you would add resistance in series. Using the 2500 ohm average resistance value, we want a potentiometer with a value slightly higher than that. Cheap pots will be 2.2k, 2.7k, 3.3k, 3.9k, or 4.7k ohms in that range. I'd go for the 4.7k ohms for a bit more range. Cut one of the sensor wires and splice the pot center tap to one of the wires, and either of the 2 outer taps to the other end of the cut. Watch your Scan Tool and turn the knob slowly to see which direction increases the effect. Higher resistance will show cooler temps.

To show hotter air or engine temp, you need to splice a pot in parallel. However, here you want a value around 10X the base value. Remember, the rating of the pot is its MAX value. Turning the knob will reduce resistance where eventually it acts as a short. For this reason, you would want the pot rated at least at 10X the base PLUS a current limiting resistor rated about base value. Let's put this together: 2.7k limiting resistor (1/4 watt 20% tolerance is just fine) and a 27k pot (again, low wattage value OK). The 2.7k resistor is soldered to one of the outer legs on one end, and one of the 2 sensor wires on the other end. The center tap of the pot is soldered to the other sensor wire. Here, lower resistance will show hotter temps.

Dartswinger70

Well-Known Member

Far out man...

To actually use the above circuits, you have to start with them at minimum value -- as close to "Off" as possible. Most ECUs will look at the temperature values of every temp sensor on the vehicle on Key-On; this would include the IAT, CTS, cabin temp sensor, even the cat temp sensor (heater circuit of the down-stream O2 sensor). If there is a consistent discrepancy in one of the sensors, the adaptive strategies will compensate around the calibration issue. The resistance change has to be slowly ramped in to chosen setting. For the CTS, ramp in the offset as the engine can handle it, then when the total circuit value reads normal operating temperature, it has to be ramped back down. Otherwise, the ECU sees an over-heating condition. On some vehicles, this will trigger the cooling fan -- which wastes fuel over-driving the alternator. Many vehicles will dump excess fuel to try to cool the engine from the inside.

This is why I would use a small 8-bit PIC processor and a digital pot. The whole "turning a knob" becomes software.

This is why I would use a small 8-bit PIC processor and a digital pot. The whole "turning a knob" becomes software.

-