An interesting thing this morning, I left the dome light and of course the battery was dead or close to it. I jumped the Van with the Dak (not running) and it was real hard to get running, cranked over a lot, after it started if I let off gas it died, would not idle. So I took battery cable off then touched the + and - for 15 seconds then jumped it again idled correctly then. I surmise that when jump starting the PCM kicked some parameters out of wack??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

318 MAX fuel economy builds?

- Thread starter gagembassett

- Start date

-

I assume you discovered the dead battery by turning the key ON and it not starting. When you turned the key ON, the PCM tried to do some initial checks, but with the low voltage, the data collected was corrupted. When you jumped it, it had to collect that data from scratch. You essentially cleared the adaptives and temporary variables when you shorted the leads forcing the PCM to start from the base tables. This is a trick used by some of the extreme fuel economy guys where the ECU figures out what they're doing and compensates over time. Clearing the adaptives at every Start keeps the MPG higher. BTW, this doesn't do much on a stock vehicle.

Whoa… this just went above my (current mental) pay grade.

- Joined

- Dec 31, 2005

- Messages

- 6,865

- Reaction score

- 4,314

Sorry but that's exactly what this place needs more of.Whoa… this just went above my (current mental) pay grade.

Honesty? LOL! Thanks, that’s one thing I’ll be, as in not telling anyone I know everything or have a solution to everything and etc…. Often when that comes up I’ll say, *I Think*Sorry but that's exactly what this place needs more of.

Or at least say my friend did this over I did this if such a the case.

Well, if I get a good nights rest and go over everything again and write down all the meanings of the letters and think about it, I’ll catch up with some reading homework.

Not saying I’ll get it in full!

There’s a lot to unpack in a bunch of terms and parts I’m not used to dealing with. But I will keep reading (and do some homework along with it) as to get some grasp on this.

Considering I’ve been out of auto mechanics for a while as my career in mechanics were on different vehicles (Trains) I still love cars and have a thirsty mine for this stuff.

Stock vehicle, so the PCM has to build from its base memory each time it’s wiped out, hmm. Now I’m wondering how the PCM changed from the 16 mpg before the trans overhaul (3 times before I got it correct) down to the 12 it’s been getting the last 3 months. Battery was disconnected when fixing trans.I assume you discovered the dead battery by turning the key ON and it not starting. When you turned the key ON, the PCM tried to do some initial checks, but with the low voltage, the data collected was corrupted. When you jumped it, it had to collect that data from scratch. You essentially cleared the adaptives and temporary variables when you shorted the leads forcing the PCM to start from the base tables. This is a trick used by some of the extreme fuel economy guys where the ECU figures out what they're doing and compensates over time. Clearing the adaptives at every Start keeps the MPG higher. BTW, this doesn't do much on a stock vehicle.

Just for kicks & giggles, try disconnecting the battery again and shorting the leads. This will wipe all adaptives again. See if it goes up. You could safely assume it won't drop below the 12 you're getting now.

- Joined

- Dec 31, 2005

- Messages

- 6,865

- Reaction score

- 4,314

Give yourself some credit, we're usually smarter than we give ourselves credit for. Some people are born with genius others like us need to work hard at it. Sometimes figuring stuff out takes hard work.Not saying I’ll get it in full!

There’s a lot to unpack in a bunch of terms and parts I’m not used to dealing with. But I will keep reading (and do some homework along with it) as to get some grasp on this.

Last edited:

So my current question is... when in terms of achieving maximum fuel economy should I raise the compression ratio up to the brink of detonation? Assuming I go the route of, let's say, an RV cam, should I push it to 10:1 or so or should I drop the the compression ratio into the 8:1 or so range? I understand compression ratio when it comes to maximizing performance but I have never in my time yet made an engine for best mpg so this is exploring the land of the unknown for me. I think if I can find one I would attempt to use the Holley Economaster carb but if not I will use a TQ with the secondaries unhooked and possibly an OD trans with roughly 3.55 gears out back. Thoughts? Input?

Rat Bastid

Dunamis Metron

So my current question is... when in terms of achieving maximum fuel economy should I raise the compression ratio up to the brink of detonation? Assuming I go the route of, let's say, an RV cam, should I push it to 10:1 or so or should I drop the the compression ratio into the 8:1 or so range? I understand compression ratio when it comes to maximizing performance but I have never in my time yet made an engine for best mpg so this is exploring the land of the unknown for me. I think if I can find one I would attempt to use the Holley Economaster carb but if not I will use a TQ with the secondaries unhooked and possibly an OD trans with roughly 3.55 gears out back. Thoughts? Input?

Why not go in between? For what you are doing you have picked both extremes.

You can run 10:1 (I would) but unless you do EVERYTHING to make sure it works I’d be between 9-9.2:1 for what you want.

Right right and that's fine. I was just curious if you are trying to oush the limits of maximum fuel efficiency is if you need to push the limits for compression too. I was already thinking about the 9:1 because I know that's the comfy area that most factories ran but didn't know if pushing it or lowering was betterWhy not go in between? For what you are doing you have picked both extremes.

You can run 10:1 (I would) but unless you do EVERYTHING to make sure it works I’d be between 9-9.2:1 for what you want.

Rat Bastid

Dunamis Metron

Right right and that's fine. I was just curious if you are trying to oush the limits of maximum fuel efficiency is if you need to push the limits for compression too. I was already thinking about the 9:1 because I know that's the comfy area that most factories ran but didn't know if pushing it or lowering was better

Any time you raise the compression you make the engine more efficient. Research expansion ratio. It’s a BIG deal.

But you have to be able to build a combination that is capable of the compression ratio you want and do it without making it miserable to tune or it’s so detonation sensitive you want to pull the pin on a grenade and drop it on the carb.

It can be a fine line there.

If that's the case I'd get a custom ground cam for a higher compression ratio but low enough lift and duration for efficiency. I'll research the expansion ratio as well I appreciate that info.Any time you raise the compression you make the engine more efficient. Research expansion ratio. It’s a BIG deal.

But you have to be able to build a combination that is capable of the compression ratio you want and do it without making it miserable to tune or it’s so detonation sensitive you want to pull the pin on a grenade and drop it on the carb.

It can be a fine line there.

Every engine combo is different. Will it detonate with 9:1 CR? Who knows, it might. As you increase CR, the power increase becomes less. It is NOT a linear curve. So you will have to decide whether increasing the CR is the worth the risk of detonation. A lower CR will allow you to use a lower octane fuel if it is available in your area. This might save you more $$ than going to higher CR that requires more expensive fuel.

A lot of the manufacturers tries heating the fuel all through the late 70s and 80s. I remember a GM staged two barrels that used heating elements built into the carburetor mounting gasket. Looked like small screens. I always wondered why there weren't some fires from that. I remember pulling off more than one that had char marks all over it.I‘m talking about heated intake manifolds and then over atomizing the fuel at the booster.

You know this. Why argue it?

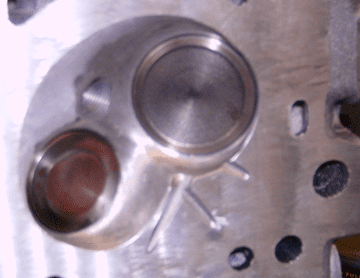

I've built a small handful of engines at around 10:1 that ran fine on 87 octane; Saturn 8-valve, Saturn 16-valve, Chrysler 2.2 TBI, a Honda 2.0 Turbo (yes, around 10:1 w/turbo), Chrysler 360, and am finishing up a Jeep 4.6 stroker (based on the 4.0) @ 10.2:1. My tricks lie in the cylinder head work, with special consideration given to the combustion chambers.

The George Arlington Moore trick of extending the intake lobe part way into the compression stroke to bleed off some of the pressure may be feasible with a custom ground cam. At any rate, the higher the CR, the higher the combustion efficiency -- within the limits of the fuel AND engine design.

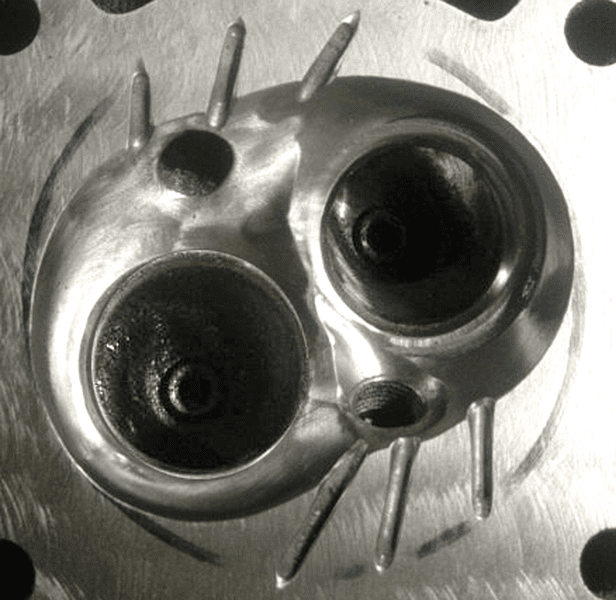

Jeep combustion chamber:

Chrysler 2.2:

Saturn 8-Valve:

The George Arlington Moore trick of extending the intake lobe part way into the compression stroke to bleed off some of the pressure may be feasible with a custom ground cam. At any rate, the higher the CR, the higher the combustion efficiency -- within the limits of the fuel AND engine design.

Jeep combustion chamber:

Chrysler 2.2:

Saturn 8-Valve:

I've built a small handful of engines at around 10:1 that ran fine on 87 octane; Saturn 8-valve, Saturn 16-valve, Chrysler 2.2 TBI, a Honda 2.0 Turbo (yes, around 10:1 w/turbo), Chrysler 360, and am finishing up a Jeep 4.6 stroker (based on the 4.0) @ 10.2:1. My tricks lie in the cylinder head work, with special consideration given to the combustion chambers.

The George Arlington Moore trick of extending the intake lobe part way into the compression stroke to bleed off some of the pressure may be feasible with a custom ground cam. At any rate, the higher the CR, the higher the combustion efficiency -- within the limits of the fuel AND engine design.

Jeep combustion chamber:

View attachment 1716024385

Chrysler 2.2:

View attachment 1716024386

Saturn 8-Valve:

View attachment 1716024387

Any consensus on what angle to cut the singh grooves in relation to the valves? Point them toward intake or exhaust valve?

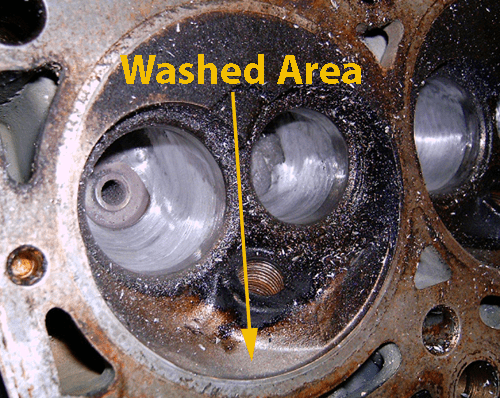

If I were handed a strange head from an engine I never worked on before, the first thing I would do is look at the story the head wants to tell. Excessive carbon build-up and clean spots are indicators of dead zones. Since velocity is your friend in both the ports and combustion chambers, dead zones are your enemy. How can I eliminate dead zones??

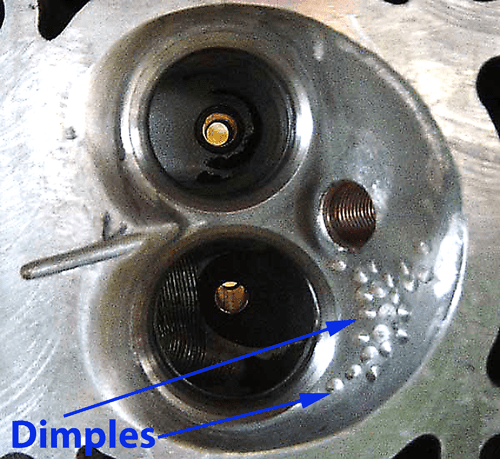

Dimples can excite an otherwise dead zone.

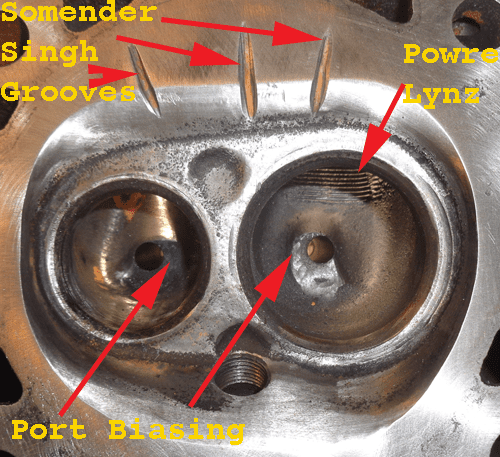

As for the Somender Singh Grooves, they serve a couple of functions:

- On the Compression Stroke, they give one last "squirt" of guided velocity to homogenize air and fuel.

- On the Power Stroke, then "blow out" the ring lands; this blows the liquid fuel out of the ring land area that was scraped from the cylinder walls on the compression stroke.

In some of the pictures posted, there is only 1 Groove, while in others there are more. I've used as many as 6 on a Ford twin-plug 2.3 Ranger. According to Somender Singh himself, the grooves should be pointed towards the spark plug to bring otherwise unburnable charge to the point of ionizing activity -- the spark kernel. As far as the other end, look for dead zones.

The Grooves on the Jeep 4.0 head were made using a hand grinder first, then a cone shaped sanding burrel to round off the sharp edges. When I had my speed shop (Powre Haus) I used my mill to gradually carve the Grooves over several passes.

Dimples can excite an otherwise dead zone.

As for the Somender Singh Grooves, they serve a couple of functions:

- On the Compression Stroke, they give one last "squirt" of guided velocity to homogenize air and fuel.

- On the Power Stroke, then "blow out" the ring lands; this blows the liquid fuel out of the ring land area that was scraped from the cylinder walls on the compression stroke.

In some of the pictures posted, there is only 1 Groove, while in others there are more. I've used as many as 6 on a Ford twin-plug 2.3 Ranger. According to Somender Singh himself, the grooves should be pointed towards the spark plug to bring otherwise unburnable charge to the point of ionizing activity -- the spark kernel. As far as the other end, look for dead zones.

The Grooves on the Jeep 4.0 head were made using a hand grinder first, then a cone shaped sanding burrel to round off the sharp edges. When I had my speed shop (Powre Haus) I used my mill to gradually carve the Grooves over several passes.

If I were handed a strange head from an engine I never worked on before, the first thing I would do is look at the story the head wants to tell. Excessive carbon build-up and clean spots are indicators of dead zones. Since velocity is your friend in both the ports and combustion chambers, dead zones are your enemy. How can I eliminate dead zones??

Dimples can excite an otherwise dead zone.

View attachment 1716024468

View attachment 1716024464

As for the Somender Singh Grooves, they serve a couple of functions:

- On the Compression Stroke, they give one last "squirt" of guided velocity to homogenize air and fuel.

- On the Power Stroke, then "blow out" the ring lands; this blows the liquid fuel out of the ring land area that was scraped from the cylinder walls on the compression stroke.

In some of the pictures posted, there is only 1 Groove, while in others there are more. I've used as many as 6 on a Ford twin-plug 2.3 Ranger. According to Somender Singh himself, the grooves should be pointed towards the spark plug to bring otherwise unburnable charge to the point of ionizing activity -- the spark kernel. As far as the other end, look for dead zones.

View attachment 1716024469

The Grooves on the Jeep 4.0 head were made using a hand grinder first, then a cone shaped sanding burrel to round off the sharp edges. When I had my speed shop (Powre Haus) I used my mill to gradually carve the Grooves over several passes.

These are the 413 motorhome engine heads I am using on my 440. Any thoughts?

Let's not get off subject with wedge heads please. You are welcome to start a thread about them.These are the 413 motorhome engine heads I am using on my 440. Any thoughts?

View attachment 1716024470

View attachment 1716024475

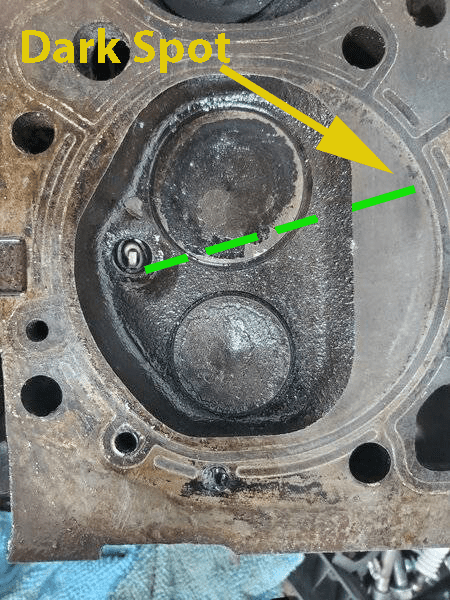

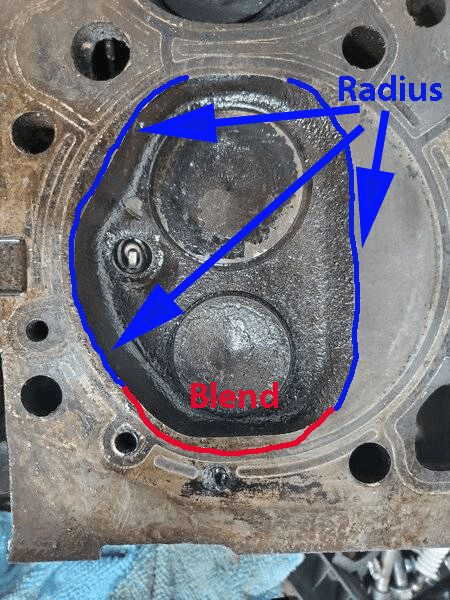

In the image below, there is a slight dark spot outlined. That would be my indicator. Based on that, I would add at least 1 Groove that dissects that dark spot, which indicates reduced activity.

Beyond the Groove, I would radius the open portion of the combustion chamber squish pad areas, extending the area around the exhaust valve to the cylinder bore.

Beyond the Groove, I would radius the open portion of the combustion chamber squish pad areas, extending the area around the exhaust valve to the cylinder bore.

- Joined

- Dec 31, 2005

- Messages

- 6,865

- Reaction score

- 4,314

Yeah you want to face the spark plug in the exhaust direction.These are the 413 motorhome engine heads I am using on my 440. Any thoughts?

-