replicaracer43

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 6,051

- Reaction score

- 7,867

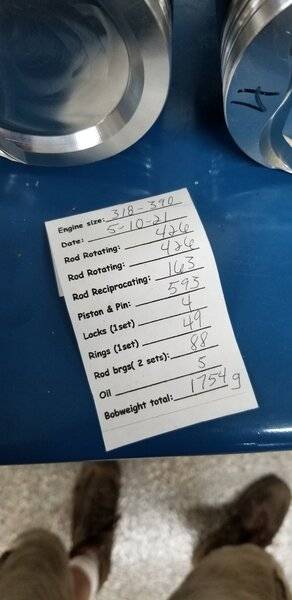

Just in case people get the idea that I'm a 318 "hater" I wanted to share this stroker build that I've been working on. The idea with this engine in a mild, daily driver engine, with emphasis on torque. This engine will be going into a 1950 dodge 1/2 ton, which is a cool truck all ready. The customer had a good 5.2 magnum block, so that's what it's based on. Scat 4" crank, Scat I beam floating rods, icon dished stroker pistons. Speedmaster heads with a touch up on the valve job, minor bowl blending, topped with a air gap intake. Block is bored and honed, rotating assembly is balanced, so now we are file fitting the rings...pictures to come, enjoy!