That special nut is supposed to be a self-locking nut, and if there is a big fat washer on the engine side of that washer, then the flat side of the nut should face the washer, and the second nut should not be there.

After so many years, the self-locking feature may have died and the second nut is there to keep the adjustment.

But guess what! with headers that system is darn near impossible to unlock, adjust, and re-lock, and with the rubber business in there, it will not hold it's adjustment for long.

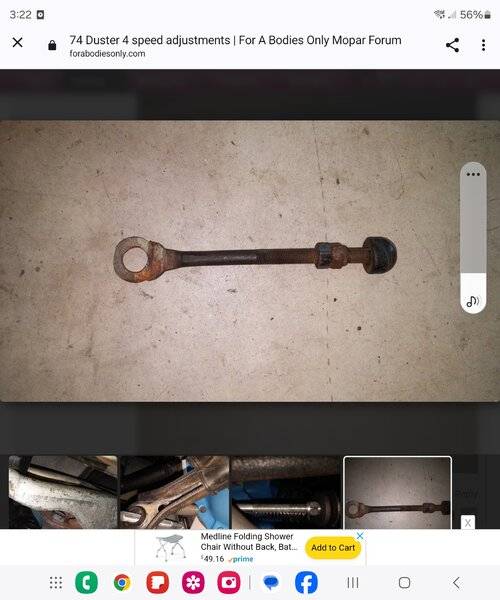

Soooooo, instead, I ordered a steel hemispherical ball and installed it on there with one non self-locking nut on each side of it. Then I use a deep-socket on a rathet, with as much extension as it takes to reach in there , and unlock the nut from the rear-end side, then reach in there with my fingers to adjust the free-play with the engine-side nut, then torque the rear-side nut back up with the ratchet. If I can find a star washer, I install that between the ball and the front nut.

Then I drill the pushrod for a cotterpin, in case the rear nut comes loose. I lost a nut one time three days from home, and adjusting that thing three times a day with hot headers and no jack, is a rear pleasure; NOT!

No, I don't remember where I got the steel half-ball, probably out of the Direct-Connection Catalog.

BTW if that is a washer welded onto the pushrod, I doubt that will last