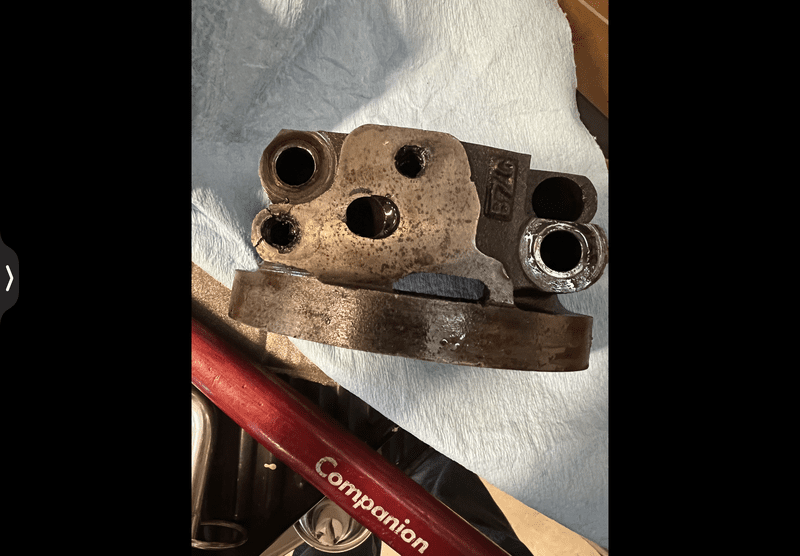

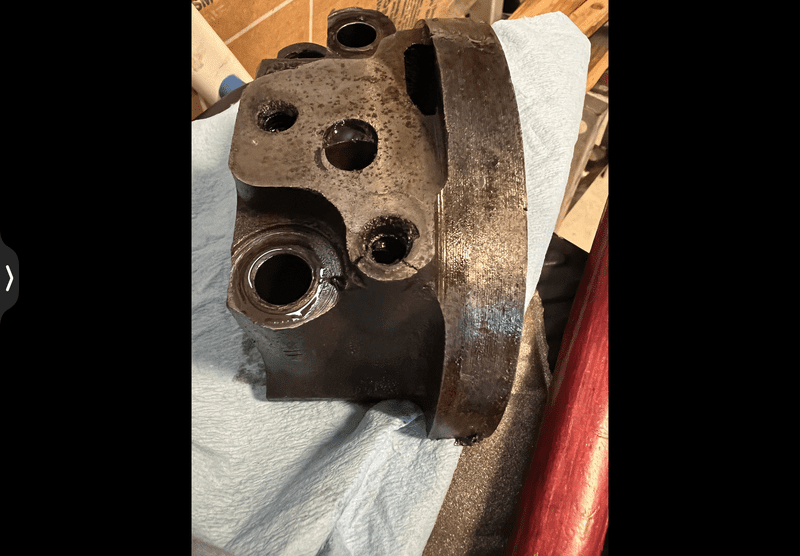

I pulled the motor and transmission on my duster (transmission needed a rebuild) and was getting ready to replace the rear main and found one of the oil pump bolt holes is cracked. Any recommendations on where to find a replacement cap? I’ll post in the WTB section but thought I’d show some pictures of the old one.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

340 rear main cap

- Thread starter HD539

- Start date

-

Newbomb Turk

Well-Known Member

That sucks. That’s the hardest cap to fit.

gzig5

Well-Known Member

I replied in your other thread but I would strongly suggest repairing that cap if possible or you will need to line bore and hone, I think. Cap could be welded or maybe a timesert thread insert would work. Might be able overbore the hole and fit a machined bushing

340sFastback

Well-Known Member

Could he JB weld a stud in that hole? One would think that would work?

But yeah can't just willy nilly replace a main cap otherwise end up eating a main bearing etc due to misalignment.

But yeah can't just willy nilly replace a main cap otherwise end up eating a main bearing etc due to misalignment.

I agree with the stud suggestion. Obviously some Azz-clown replaced the oil pump once in that engine and didn't have it fully seated. Red Lock-tite the stud. If you know or can find someone who can weld cast iron have them spot weld that cracked piece for peace of mind. But if the threaded hole goes quite a bit below the cracked area you will be fine

Have it spray welded and fixed at a machine shop. Replacing the cap would mean tearing the engine completely down to line bore it.

Remember if spray welding it, The shop should have a small block mopar block there to have it bolted to and torqued when welding the is being done. It should be torqued to a block then heated prior to welding. They will have to resurface the oil pump surface. We already spray welded lifter bores back in race engines. Just did a 440 with the water pump housing surface broke off . Most machine shops Spray weld. That is the correct way to fix it right.

Remember if spray welding it, The shop should have a small block mopar block there to have it bolted to and torqued when welding the is being done. It should be torqued to a block then heated prior to welding. They will have to resurface the oil pump surface. We already spray welded lifter bores back in race engines. Just did a 440 with the water pump housing surface broke off . Most machine shops Spray weld. That is the correct way to fix it right.

Dan the man

Well-Known Member

I have a simple solution to your problem, just simply replace the rear cap from a 318, as the 318's and the 340's have the same main bearing caps. I'm surprised that no one else thought of this. 318's are everywhere so locating one should be easily done. I can't believe that none of mopar specialists thought of this.

Dan the man

Well-Known Member

I checked and they both have the same length main bearing cap bolts. Why pay more than you have too when the 318 cap will work.

Read Post #4I have a simple solution to your problem, just simply replace the rear cap from a 318, as the 318's and the 340's have the same main bearing caps. I'm surprised that no one else thought of this. 318's are everywhere so locating one should be easily done. I can't believe that none of mopar specialists thought of this.

340sFastback

Well-Known Member

Main caps are lined honed matched to each specific block as part of initial block machining after blocks are cast. You can not take ANY main cap off of ANY block and willy nilly slap it on another block without line honing the mains again. Otherwise the cap will be misaligned bind and eat the bearing. At which point the engine will need an entire rebuild. Super bad idea.I have a simple solution to your problem, just simply replace the rear cap from a 318, as the 318's and the 340's have the same main bearing caps. I'm surprised that no one else thought of this. 318's are everywhere so locating one should be easily done. I can't believe that none of mopar specialists thought of this.

Now if this was an engine being rebuilt sure go find a 318 cap line hone it to the 340 block good to go. But the person asking is not rebuilding he is looking to get it running without rebuild.

grimreaper

Cross Member

If you grab a main cap from another engine there is a high probability that it won't align close enough to line bore. You might have to try half a dozen caps before you find one that is close enough. ( Of course you MIGHT get lucky on the first one.....but I never have!)

Newbomb Turk

Well-Known Member

I have a simple solution to your problem, just simply replace the rear cap from a 318, as the 318's and the 340's have the same main bearing caps. I'm surprised that no one else thought of this. 318's are everywhere so locating one should be easily done. I can't believe that none of mopar specialists thought of this.

If it was only that simple. The replacement cap has to be a damn close fit to start with or you’ll never get it to fit.

Even when it’s close, it’s a PITA to get everything where it should be.

Thanks everyone , lots to consider. I’ll update the post when I figure out what direction to go.

340sFastback

Well-Known Member

Hopefully willy nilly slapping a 318 cap on there without full tear down and line hone is out, right?Thanks everyone , lots to consider. I’ll update the post when I figure out what direction to go.

mygasser

Well-Known Member

where's the guy on here who chop saws piston tops? bet he's got a diy tool to make a 318 cap fit perfect

Dan the man

Well-Known Member

My bad, I forgot that he's not doing a rebuild. Question, if he has the cap welded and finished ground or machined wouldn't the heat affect the shape of the cap even if it's only a minor amount?Hopefully willy nilly slapping a 318 cap on there without full tear down and line hone is out, right?

I have a simple solution to your problem, just simply replace the rear cap from a 318, as the 318's and the 340's have the same main bearing caps. I'm surprised that no one else thought of this. 318's are everywhere so locating one should be easily done. I can't believe that none of mopar specialists thought of this.

Actually, 340 caps are not the same as 318. The journal diameter is the same but the 340 caps are a little beefier. However, I think the rear cap is the same.

I would try a thread-sert there or the spray weld option. Not enough meat for a regular heli-coil. You could also braze it up and re-tap it. Braze is some tough stuff.

Dan the man

Well-Known Member

I did read that the 340 caps are a little taller than the 318's. I'd rather have them wider as this would help make the bottom end stronger. I did read that the rear main cap is the sameActually, 340 caps are not the same as 318. The journal diameter is the sdame but the 340 caps are a little beefier. However, I think the rear cap is the same.

I would try a thread-sert there or the spray weld option. Not enough meat for a regular heli-coil. You could also braze it up and re-tap it. Braze is some tough stuff.

Common first time error. At least when installing from underneath the vehicle. Although when I did it, cracked the oil pump. I think that's the most common breakage when the nose isn't fully seated.I agree with the stud suggestion. Obviously some Azz-clown replaced the oil pump once in that engine and didn't have it fully seated. Red Lock-tite the stud. If you know or can find someone who can weld cast iron have them spot weld that cracked piece for peace of mind. But if the threaded hole goes quite a bit below the cracked area you will be fine

The main caps are machined and line bored to the block it came from. So yes it could be done but the engine will have to be tore down and line bored or possible bearing failure will happen. He could take the chance but is it worth it.I have a simple solution to your problem, just simply replace the rear cap from a 318, as the 318's and the 340's have the same main bearing caps. I'm surprised that no one else thought of this. 318's are everywhere so locating one should be easily done. I can't believe that none of mopar specialists thought of this.

When replacing a main cap usually the mating surface of the cap should be cut then the cap should be sized to the block bore.

like_A_pike

that's not factory

I suspect that I broke mine trying to torque a bolt that was too long in that same flange. I had Angeles Machine Works Inc. (PA Wa.) welded a stud and resurfaced the pump face in 2012. 35k miles on it so far! Good luckThanks everyone , lots to consider. I’ll update the post when I figure out what direction to go.

Last edited:

-