But its not lose from therenot being pressure on it from the spring. its lose because there is so much space between the rocker and the shaft..like the two big holes in the rocker is very worn our and too big now for the shaft. i may be thinking to simple here, but thats what it looked like to me. There was about a 1/16th inch between the shaft and rocker when there was pressure on it from the spring and it was being pushed UP.

Jeff

The problem comes about for many different reasons and sometimes a combination of those reasons. The three main reasons for this to happen are improper preload on the hydraulic lifters, wrong breakin oil and excessive spring pressure.

The rocker arms should fit fairly snug on the shafts. Since they don't, the rocker arms have actually stretched under the strain. This caused a jack hammer effect on your lifters and camshaft. While many say that they have used stock rockers on a big lift cam (myself included), the Crane ductile iron adjustable rockers or their Gold Race adjustable rockers are a huge upgrade.

The adjustability eliminates the issue with incorrect preload, as long as they are adjusted correctly. When the head or block deck is shaved, the preload increases due to the push rod now being too long.

The issue with break in oil is a big one. Modern oils have far less ZDDP in them and do not offer the protection during break in that a flat tappet cam requires. The lobe on a flat tappet cam actually has a slight angle to it at the highest lift point (if my memory serves me correctly, it is as much as .004" of taper at max lift). This causes the lifter to rotate as it rides over the cam lobe and will allow it to live a long and healthy life. Once that taper is worn off, it's only a matter of time before that engine is completely shot.

On the upside: after you get the mechanical problems sorted out and all bad parts replaced, use a bottle of STP oil treatment as an assembly lube and poor whatever you don't use for assembly into the engine for break-in. The main ingrediant in the oil treatment is ZDDP. This will allow the cam to break in safely....as long as the other problems mentioned are rectified.

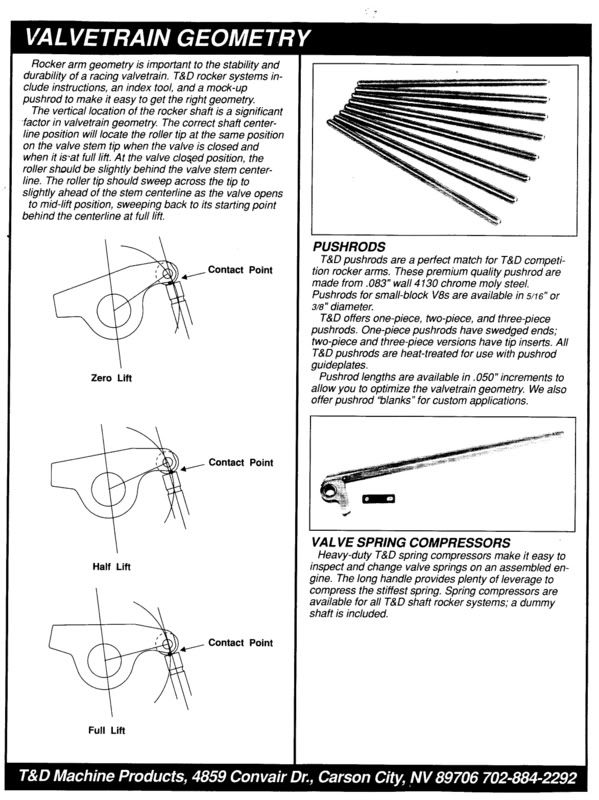

Pay very close attention to everything in the valvetrain and how they relate to each other. Here is T&D's recommendations on rocker to valve stem alignment. If you can not get the alignment shown on this geometry sheet, regardless of rocker type, your push rods are not the right length.

Good luck, Dave

P.S. It is also possible to shim the rocker shaft up to get the correct geometry. Also, the installed height of the valve needs to match the head and rockers...in other words, you can't shim the shaft down.

Crane has made me push rods in an hours notice to my exact specs for $100. They are only about 35 miles from me in Daytona.

Maybe not so obviously, anything you change in the valvetrain effects everything in the valvetrain.