Run a small bead UNDER the tab on head gasket. Fold it down on top of that bead. Then run another small bead on top of the folded down tab. Then run your head along the China wall. No leaks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

360 LA getting oil in #3 cylinder.

- Thread starter tinman2

- Start date

-

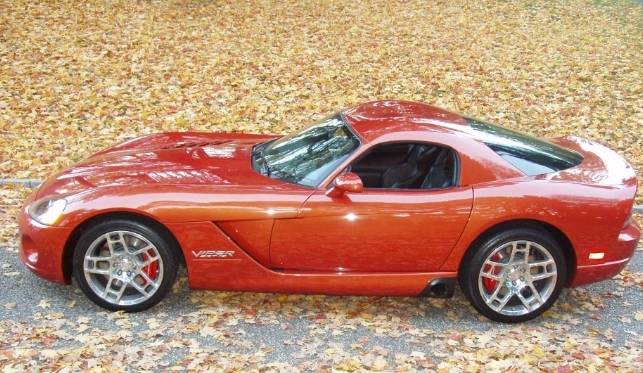

That's pretty snazzy looking. T5 color code?

This really makes me want to paint mine back to the original color. (My color code is T5)

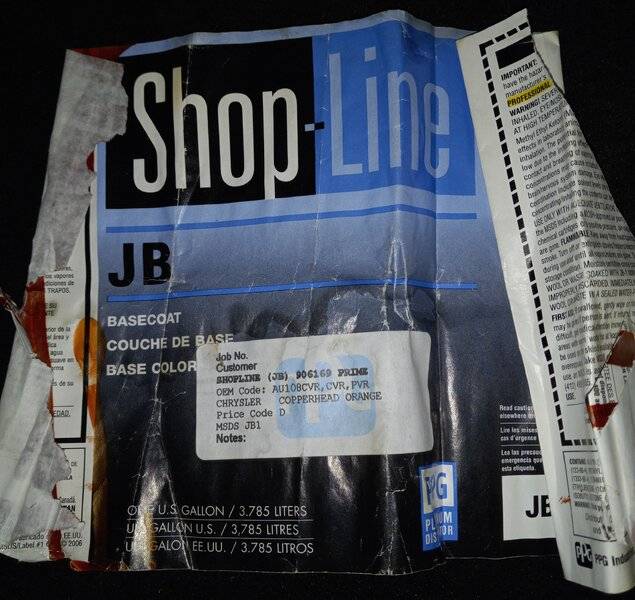

Luckily, this was left in the glove box. That's all I know about the paint.

I looked up Chrysler Copperhead Orange

and this came up. Looks about right.

and this came up. Looks about right.

Looking over everything before starting reassembly. Kinda wish the head bolts were a little longer. I screwed the head bolts into the block just to see how far they would go and all but the rear long bolts on each side would bury the threads even with the deck. The rear long bolts had about ½ round of threads still showing.

Then I put the old ARP bolts with washers through one head and this is what I get.

Only about ½ the threads are going into the block. And since the threads are countersunk into the block, and with headgaskets, I'm getting less than this.

Only about ½ the threads are going into the block. And since the threads are countersunk into the block, and with headgaskets, I'm getting less than this.

Seems like I read somewhere that a bolt should thread in at least 1½ times bolt diameter. That would be 0.75" for 0.5" bolt and there is only 0.67 sticking out of the head.

Would ARP studs do better? Thanks in advance.

Then I put the old ARP bolts with washers through one head and this is what I get.

Seems like I read somewhere that a bolt should thread in at least 1½ times bolt diameter. That would be 0.75" for 0.5" bolt and there is only 0.67 sticking out of the head.

Would ARP studs do better? Thanks in advance.

74 360 dart sport

Well-Known Member

I will take it off your handsThanks to all. I'll tinker with it more tomorrow.

Just thinking back... when removing the headbolts, I was surprised, after loosening them, by how few turns it took to remove them.

After reading what I could find on this site about using studs, and bottoming them out, they must be longer. Then I read about the larger diameter of the studs blocking oil flow to the rocker shafts. And studs may also cause interference with header flanges.

My thoughts about using studs are for more thread engagement deeper in the block hopefully resulting in less deck distortion. ???

After reading what I could find on this site about using studs, and bottoming them out, they must be longer. Then I read about the larger diameter of the studs blocking oil flow to the rocker shafts. And studs may also cause interference with header flanges.

My thoughts about using studs are for more thread engagement deeper in the block hopefully resulting in less deck distortion. ???

74 360 dart sport

Well-Known Member

You need to pull the motor and do it right

Phreakish

Well-Known Member

Just thinking back... when removing the headbolts, I was surprised, after loosening them, by how few turns it took to remove them.

After reading what I could find on this site about using studs, and bottoming them out, they must be longer. Then I read about the larger diameter of the studs blocking oil flow to the rocker shafts. And studs may also cause interference with header flanges.

My thoughts about using studs are for more thread engagement deeper in the block hopefully resulting in less deck distortion. ???

What bolts did you buy? ARP lists 144-3602 for stock heads.

What heads do you have? Some aftermarket heads required the longer sets used for many Edelbrock heads. Or you might have accidentally bought some which are intended for other heads - ARP has at least 3 different listings on summit depending on the heads.

The engine already had ARP head bolts. Those are the ones I measured.What bolts did you buy? ARP lists 144-3602 for stock heads.

What heads do you have? Some aftermarket heads required the longer sets used for many Edelbrock heads. Or you might have accidentally bought some which are intended for other heads - ARP has at least 3 different listings on summit depending on the heads.

I bought a new set of ARP head bolts #144-3602. I haven't opened the new box in case I decide to return them and go with studs. Standard LA 360 block and heads.

The engine already had ARP head bolts. Those are the ones I measured.

I bought a new set of ARP head bolts #144-3602. I haven't opened the new box in case I decide to return them and go with studs. Standard LA 360 block and heads.

How many bolts are to short. I’m guessing four. (Both heads) If so give me the length and I’ll check my old stock.

Copied from Fastenal website: https://www.fastenal.com/fast/services-and-solutions/engineering/screw-thread-design

"It appears that one could theoretically increase the thread strength by increasing the length of engagement. However, as illustrated in the Load Distribution chart above, the first thread will be taking the majority of the applied load. For carbon steel fasteners (including tapped holes) the length of engagement would be limited to approximately one nominal diameter (approximately 1-1/2 times the diameter for aluminum). After that, there is no appreciable increase in strength. Once the applied load has exceeded the first thread's capacity, it will fail and subsequently cause the remaining threads to fail in succession."

"It appears that one could theoretically increase the thread strength by increasing the length of engagement. However, as illustrated in the Load Distribution chart above, the first thread will be taking the majority of the applied load. For carbon steel fasteners (including tapped holes) the length of engagement would be limited to approximately one nominal diameter (approximately 1-1/2 times the diameter for aluminum). After that, there is no appreciable increase in strength. Once the applied load has exceeded the first thread's capacity, it will fail and subsequently cause the remaining threads to fail in succession."

They all have about the same amount coming through the head. According to the Fastenal website, they should be long enough. I did go ahead and order the ARP stud set. I never thought about being able to install the studs with the heads in place since the engine is in the car until I read it here. Now if the rocker shaft oiling isn't a problem like I read about on FABO today.How many bolts are to short. I’m guessing four. (Both heads) If so give me the length and I’ll check my old stock.

They all have about the same amount coming through the head. According to the Fastenal website, they should be long enough. I did go ahead and order the ARP stud set. I never thought about being able to install the studs with the heads in place since the engine is in the car until I read it here. Now if the rocker shaft oiling isn't a problem like I read about on FABO today.

If you have a friend with a lathe you can give the stud a little clearance kiss if needed. I do my by hand if needed

Ohhh and it would only be two studs, one on each head.If you have a friend with a lathe you can give the stud a little clearance kiss if needed. I do my by hand if needed

Studs should be delivered Wednesday. I'll see how everything looks and fits together.Ohhh and it would only be two studs, one on each head.

Studs should be delivered Wednesday. I'll see how everything looks and fits together.

I hope you got the studs with the Allen heads. It makes installing them and removing them so much easier. Especially with the heads on in the car.

I bought a set of these during the Black Friday 40% off sale just to have them here.

Mopar Chrysler SB 318 340 360 12 Point Head Stud Kit

Mopar Chrysler SB 318 340 360 12 Point Head Stud Kit

DODGE ARP 144-4001 ARP Pro Series Cylinder Head Studs | Summit Racing

Free Shipping - ARP Pro Series Cylinder Head Studs with qualifying orders of $109. Shop Cylinder Head Fasteners at Summit Racing.

These are the ones I ordered.

Okķkk. I see the studs have a fine thread on one end where the washers and nuts go on. Instructions say torque to 110 lbs. With a finer thread, seems to me, it would be like a lower gear or shallower ramp. Or traveling a farther distance to rise the same amount. So with that mechanical advantage, wouldn't torqueing the same amount put more clamping force on the studs? I don't want to warp the block deck after I worked hard to get it level.

DODGE ARP 144-4001 ARP Pro Series Cylinder Head Studs | Summit Racing

Free Shipping - ARP Pro Series Cylinder Head Studs with qualifying orders of $109. Shop Cylinder Head Fasteners at Summit Racing.www.summitracing.com

These are the ones I ordered.

@pittsburghracer

Phreakish

Well-Known Member

The difference between fine and coarse threads is so minor that it typically doesn't play into torque calculations.

A super-fine thread might have an impact, but friction dominates the equations by orders of magnitude. You've got nothing to worry about.

A super-fine thread might have an impact, but friction dominates the equations by orders of magnitude. You've got nothing to worry about.

I’d be more concerned about using the recommended lubricant

Will do. I bought a set of ARP thread cleaner chasers and cleaned out all the bolt holes.I’d be more concerned about using the recommended lubricant

Fine threads are stronger than coarse threads of the same size.

Got the heads on with the Fel-Pro 1008 head gaskets and ARP 144-4001 head stud kit using a good coat of ARP Ultra-Torque assembly lube.

It was a pita with the engine in the car and headers in the way. I jacked up the driver's side of the engine first because the other head was off and it gave more room to get a straight shot at the lower studs above the headers flanges. On the passenger side, the transmission dipstick tube was in the way but the headers dropped down lower.

Next, I got the headers bolted up using high temp sealer on the end bolts.

It was a pita with the engine in the car and headers in the way. I jacked up the driver's side of the engine first because the other head was off and it gave more room to get a straight shot at the lower studs above the headers flanges. On the passenger side, the transmission dipstick tube was in the way but the headers dropped down lower.

Next, I got the headers bolted up using high temp sealer on the end bolts.

-

Similar threads

- Replies

- 18

- Views

- 7K