Val360

Member

Hi all,

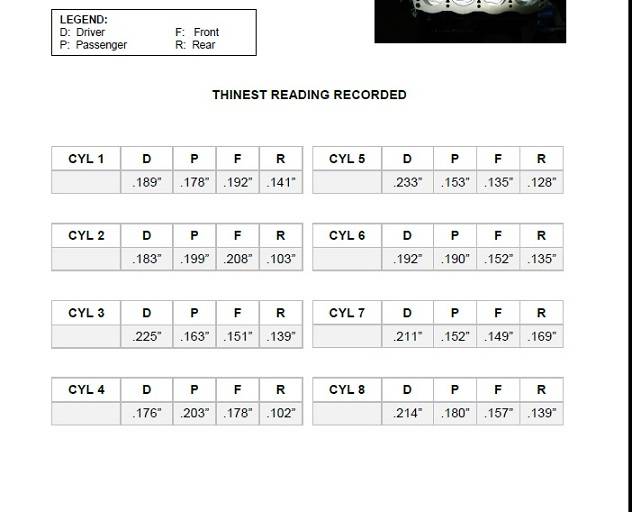

I've just recently had my 360 block sonic tested to see if I could possibly bore it out to .060" over as it already sits at .040". The results I got from the sonic test showed Cyl 2 and 4 to be just over .100" on the rear of the bores which has me a little worried. Just after some recommendations on what path to go down, I was possibly looking at offset sleeving the two bores and then offset boring (offset towards front of block) the block to hopefully gain a bit in these two areas. I'm open to all opinions and suggestions

Little info on build - Engine I will be assembling will look something like 4.00" stroke, 10.5:1 comp, RHS 'X' heads, mechanical solid cam in a 1450kg (3200lb) car with a 727, 3800 stall and 4.11 gears. Will be mainly for street use. (I'm in AUS so the passenger and driver will be opposite)

I've just recently had my 360 block sonic tested to see if I could possibly bore it out to .060" over as it already sits at .040". The results I got from the sonic test showed Cyl 2 and 4 to be just over .100" on the rear of the bores which has me a little worried. Just after some recommendations on what path to go down, I was possibly looking at offset sleeving the two bores and then offset boring (offset towards front of block) the block to hopefully gain a bit in these two areas. I'm open to all opinions and suggestions

Little info on build - Engine I will be assembling will look something like 4.00" stroke, 10.5:1 comp, RHS 'X' heads, mechanical solid cam in a 1450kg (3200lb) car with a 727, 3800 stall and 4.11 gears. Will be mainly for street use. (I'm in AUS so the passenger and driver will be opposite)