ratty dart 340

Well-Known Member

Hey everyone, I was installing my rpm air gap intake on my LA 360 and I noticed that there is no where for water to flow through the intake from the head on the back. Is this ok? Does it need to be blocked or something?

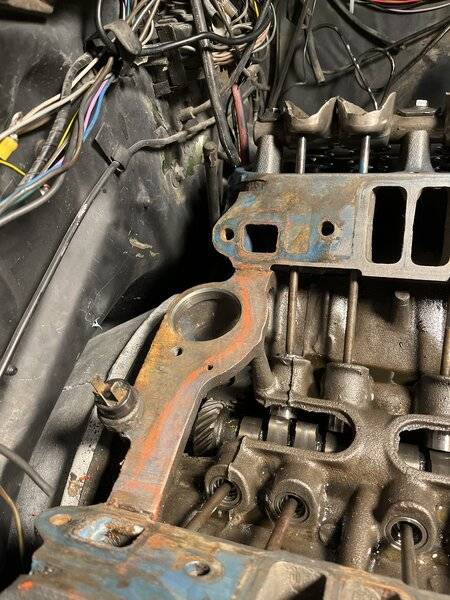

Here is a pic of the water jacket on the back of the heads.

Here is a pic of the intake. There is no where for water to flow on the intake.

I am replacing the new intake gaskets with other brand new gaskets because water was leaking from said water passages.

Do I just need to use more rtv or a faulty gasket?

Any help would be amazing. Thank you.

Here is a pic of the water jacket on the back of the heads.

Here is a pic of the intake. There is no where for water to flow on the intake.

I am replacing the new intake gaskets with other brand new gaskets because water was leaking from said water passages.

Do I just need to use more rtv or a faulty gasket?

Any help would be amazing. Thank you.