Tsully

Well-Known Member

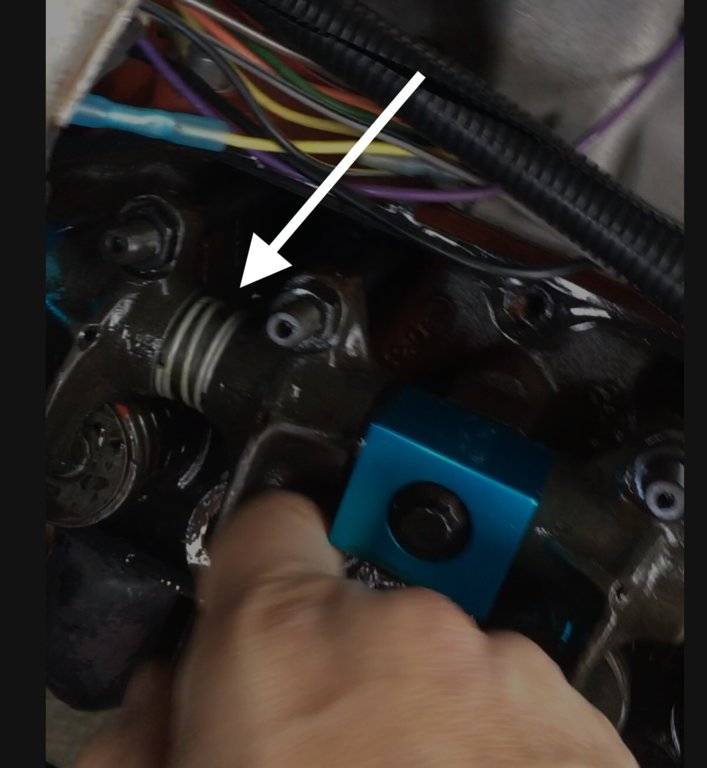

When I bought my B’Cuda it kept hearing a slight knock at idle and would go away around 1500 rpm’s. I have adjustable rockers and was wonder if it’s normal for them to “knock” at idle or if the spreader spring is to weak to keep it from walking? I haven’t adjusted them yet wanted advice beforehand. I’ve had sets on a race car before but it was in Small block chevy and had no knock issues and I’ve owned other mopars with stock rockers and no issues. Was contemplating getting a stock stamped set and place these aside until I build the 451 stroker or Just leave them on adjust and drive! Sorry the pic is from a video of me pushing over the arm and it wouldn’t let me upload it.

Motor now is 60 over 383 with 516 heads and a mild cam.

Motor now is 60 over 383 with 516 heads and a mild cam.

Last edited: