You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

440 Help Needed

- Thread starter carfreak6970

- Start date

-

For me that would be very predictable...Diagnosis by keyboard is virtually always a teeth pulling exercise..

. Don't mind me. I am just a dentist.

. Don't mind me. I am just a dentist.carfreak6970

Well-Known Member

.After watching the video of this engine idling, I'm curious if the timing is stable. If the distributor has light springs, the advance could be bouncing and that would make the idle hunt up and down. A quick check with a timing light would either prove that condition or rule it out.

The distributor does have lighter springs. I am going to try and remove the distributor next time I am home and make sure things are together properly on it.

Sure seems like a vacuum leak.

Do you have a sure fire way to find this out? I tried the propane and carb cleaner method. What areas would you suggest? I tried all connections to the intake manifold and carb.

Diagnosis by keyboard is virtually always a teeth pulling exercise..

it really is, but as of now I have no other way of getting help on this.

Before you pull the distributor, warm the engine up and check the timing at your idle speed. Check to see if the timing is stable, or bouncing around.

.

Do you have a sure fire way to find this out? I tried the propane and carb cleaner method. What areas would you suggest? I tried all connections to the intake manifold and carb.

Start with the basic set up. Remove and plug all vacuum carb connections such as PCV, distributor vacuum advance, etc. Disconnect and plug power brake booster port? Is your vacuum still 10-15? Did the reading stabilize? I can't tell from your video what you distributor vacuum advance is connected to - ported or manifold source?

Carter AVS has a choke pull off that can be a vacuum leak source too. Also, a vacuum leak and your throttle opening position on the AVS may cause the metering rods to lift (or bounce) out of then jets. Holley power valve (what size is it?) would be affected in the same way I believe.

Last edited:

carfreak6970

Well-Known Member

It has been awhile... another car has taken priority, but! that other car has reached a point and is at a different location that I can focus on this.

So I did check a couple things. The fuel pressure while cranking the engine was 7-8 psi.

Once I hooked up the fuel line again, and got it running I was not seeing any fuel come from the boosters while at idle.

However, I was running the car inside. I had exhaust hoses connected to the tail pipes to route the exhaust out of the building.

I did what someone here suggested and opened up the idle bleed screws a half a turn and was able to close the throttle blades down. I opened the idle bleed screws another half a turn from the original 1-1.5 turn out from the seated and was able to close the throttle blades down some more. These were my following readings:

650 rpm

11 inHg

12 deg BTDC.

Which is a much better improvement! The timing light did not show the timing was jumping around as much as it was before. I Increased the initial timing 3 degrees to get the following:

725 rpm

12 inHg

15 deg BTDC.

I am not to sure what changed between the last time I put the timing equipment on the car and now. The only stuff that did change is sta-bil is in the fuel tank, the car had exhaust hoses on and maybe an additional 100 miles or so were put on the car.

This is all good news! so thank you everyone for your help. So next course of action is Id like to remove the carb from the car and measure the best I can the transfer slot opening. I believe that is to be set at .040" and with all of this monkeying around I did with the car I lost track of what the opening was. So I will measure what it is, and see if I can get it as close to .040 as possible.

I also removed the distributor from the car and I am going to put it on my distributor machine to see if I can replicate any issue I was seeing with the car. I want to check the ignition curve of the dizzy now that my knowledge of how everything works together has increased (hopefully).

if anyone else has any other suggestions I am all ears

So I did check a couple things. The fuel pressure while cranking the engine was 7-8 psi.

Once I hooked up the fuel line again, and got it running I was not seeing any fuel come from the boosters while at idle.

However, I was running the car inside. I had exhaust hoses connected to the tail pipes to route the exhaust out of the building.

I did what someone here suggested and opened up the idle bleed screws a half a turn and was able to close the throttle blades down. I opened the idle bleed screws another half a turn from the original 1-1.5 turn out from the seated and was able to close the throttle blades down some more. These were my following readings:

650 rpm

11 inHg

12 deg BTDC.

Which is a much better improvement! The timing light did not show the timing was jumping around as much as it was before. I Increased the initial timing 3 degrees to get the following:

725 rpm

12 inHg

15 deg BTDC.

I am not to sure what changed between the last time I put the timing equipment on the car and now. The only stuff that did change is sta-bil is in the fuel tank, the car had exhaust hoses on and maybe an additional 100 miles or so were put on the car.

This is all good news! so thank you everyone for your help. So next course of action is Id like to remove the carb from the car and measure the best I can the transfer slot opening. I believe that is to be set at .040" and with all of this monkeying around I did with the car I lost track of what the opening was. So I will measure what it is, and see if I can get it as close to .040 as possible.

I also removed the distributor from the car and I am going to put it on my distributor machine to see if I can replicate any issue I was seeing with the car. I want to check the ignition curve of the dizzy now that my knowledge of how everything works together has increased (hopefully).

if anyone else has any other suggestions I am all ears

67Dart273

Well-Known Member

Try this. Forget the timing light temporarily. You must adjust back and forth between timing, idle speed screws, and idle mixture

Try timing it with a vacuum gauge or tach for max RPM/ max vacuum. Warm of course. Adjust idle mixture screws for max RPM/ vacuum and keep backing down speed screw to keep it within reason of idle speed. When you have it running with timing at max RPM, retard timing just a bit, until RPM/ vacuum barely drops/. At that point readjust mixture and idle RPM and then grab the timing light and see where it sits

YOU MAY HAVE cam timing off some do you know where it's degreed?

Try timing it with a vacuum gauge or tach for max RPM/ max vacuum. Warm of course. Adjust idle mixture screws for max RPM/ vacuum and keep backing down speed screw to keep it within reason of idle speed. When you have it running with timing at max RPM, retard timing just a bit, until RPM/ vacuum barely drops/. At that point readjust mixture and idle RPM and then grab the timing light and see where it sits

YOU MAY HAVE cam timing off some do you know where it's degreed?

67Dart273

Well-Known Member

Some of the Holleys you do not need to drill the throttles. Instead there's a stop screw for the rear barrels you can crack the rear butterflies (secondaries) with the stop screw instead of drilled bladesTry this. Forget the timing light temporarily. You must adjust back and forth between timing, idle speed screws, and idle mixture

Try timing it with a vacuum gauge or tach for max RPM/ max vacuum. Warm of course. Adjust idle mixture screws for max RPM/ vacuum and keep backing down speed screw to keep it within reason of idle speed. When you have it running with timing at max RPM, retard timing just a bit, until RPM/ vacuum barely drops/. At that point readjust mixture and idle RPM and then grab the timing light and see where it sits

YOU MAY HAVE cam timing off some do you know where it's degreed?

carfreak6970

Well-Known Member

I will have to see if there is a screw for the secondaries. I didnt notice one before.Some of the Holleys you do not need to drill the throttles. Instead there's a stop screw for the rear barrels you can crack the rear butterflies (secondaries) with the stop screw instead of drilled blades

I do not know where this cam is degreed. It is a single bolt cam, but I guess I can check it.

I can try that method of setting the car up.

My .02. Quit thinking carb and drilling holes etc.

Get rid of the points ignition or find a new replacement to put in its place if you are hung up on points. 25 degrees is way off.

We are taking 50 year old stuff here. I am 51 and have a lot of loose bushings and spring too. Nothing stays in factory spec even if you check the dwell.

You have to establish a reliable baseline before you start chasing vacuum and fuel issues.

It’s still an air pump

Get rid of the points ignition or find a new replacement to put in its place if you are hung up on points. 25 degrees is way off.

We are taking 50 year old stuff here. I am 51 and have a lot of loose bushings and spring too. Nothing stays in factory spec even if you check the dwell.

You have to establish a reliable baseline before you start chasing vacuum and fuel issues.

It’s still an air pump

Babyblue66

Cool dude

Thats not a big cam. With good compression and the timing dialed in right. It should idle just fine with a 750 Holley assuming everything is in correct working order. Even at 15 degrees at idle, it should run good. Although I'd probably add more, depending on what the motor likes. Also, these motors run a bit stinky with duration and overlap.

Cam, Cam, Cam

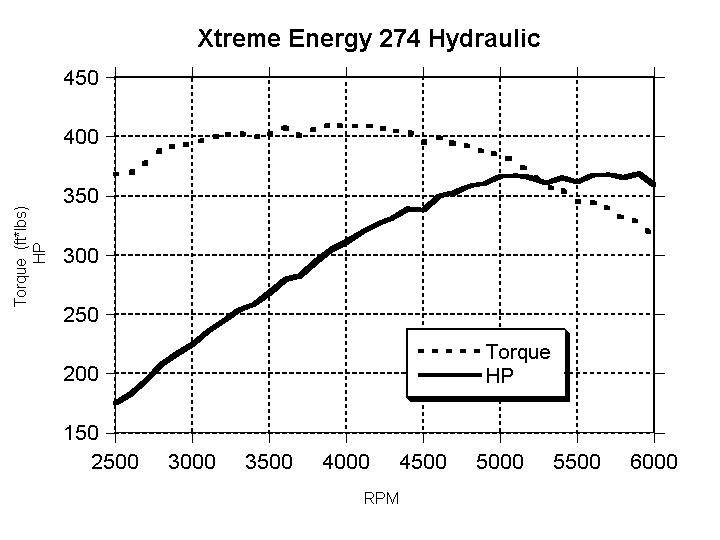

Xtreme Energy XE274H Hydraulic Flat Tappet Camshaft

Very strong mid-range, torque & throttle response.

XE274H cam has an operating range of 1800 - 6000 rpm, with very strong mid range.

So you are not going to get a very good idle out of it, with the valve overlap at idle.

Camshafts control the amount of time that your intake and exhaust valves are open. An increase in camshaft size will increase performance while also increasing how rough your vehicle's idle is.

Your quote from your previous post:

"The engine is a fairly stock rebuild. It was bored .020" over and has a hotter cam in it."

______________________

Sounds like you and your Dad just want something that runs right and is reliable.

Xtreme Energy XE274H Hydraulic Flat Tappet Camshaft

Very strong mid-range, torque & throttle response.

| Operating Range: | 1800-6000 RPM |

| Duration Advertised: | 274° Intake / 286° Exhaust |

| Duration @ .050'' Lift: | 230° Intake / 236° Exhaust |

| Valve Lift w/1.5 Rockers: | .490'' Intake / .490'' Exhaust |

| Lobe Separation Angle: | 110° |

XE274H cam has an operating range of 1800 - 6000 rpm, with very strong mid range.

So you are not going to get a very good idle out of it, with the valve overlap at idle.

Camshafts control the amount of time that your intake and exhaust valves are open. An increase in camshaft size will increase performance while also increasing how rough your vehicle's idle is.

Your quote from your previous post:

"The engine is a fairly stock rebuild. It was bored .020" over and has a hotter cam in it."

______________________

Sounds like you and your Dad just want something that runs right and is reliable.

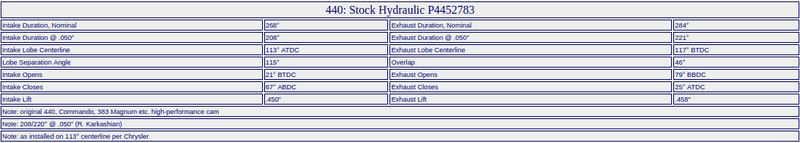

Here are the Stock 440 Camshaft specs so you have the numbers to compare things to:

440 Stock Cam

P4452783

.450 / .468 Lift

268* / 284* Duration

@.050 208* Intake

@.050 221* Exhaust

113* Lobe Center

Original 440, Commando, 383 Magnum etc.

440 Stock Cam

P4452783

.450 / .468 Lift

268* / 284* Duration

@.050 208* Intake

@.050 221* Exhaust

113* Lobe Center

Original 440, Commando, 383 Magnum etc.

Babyblue66

Cool dude

Actually it's this cam. Made by Elgin, melling, etc. I also degreed a mopar performance magnum cam. Same specs.Here are the Stock 440 Camshaft specs so you have the numbers to compare things to:

440 Stock Cam

P4452783

.450 / .468 Lift

268* / 284* Duration

@.050 208* Intake

@.050 221* Exhaust

113* Lobe Center

Original 440, Commando, 383 Magnum etc.

View attachment 1716026351

carfreak6970

Well-Known Member

Thank you all for that information. I was able to get the distributor on the machine a couple nights ago and realized the ignition curve is spot on to the 70 440 magnum spec. Which I guess is good, but while looking at it I noticed there was excessive play in the shaft. I was able to move the shaft radially, which would affect the opening and closing of the points. I checked the slant six distributors I had laying around (rebuilt and used ones) and I did not notice any play. I called up a friend to check his stash of RB engine distributors and his had no play at all. So whether or not this worn bushing, or bent shaft, is contributing to my problem (or is my problem) is unknown. But it sure is not helping it. I have a new electronic distributor for this car that I will put on my machine and check the curve before I try and install it on the car.

-