I was very busy the past few days because so I had no time to actually take part to the conversation. Fo sure imma take my time and gonna check out everything I can to complete the chart(s). But imma gonna do it after xmas.See the first photo in post 36, and the link to the dealer book in post 47.

For the actual wire connections on this car see the OP's photos. Clearly there are some differences between what the book shows and what is there. Agree the book's diagrams are not error free.

It will be interesting to learn what @SlantedMark4 finds with respect to the alternator tag and other details.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

65amp wiring/trouble shooting

- Thread starter SlantedMark4

- Start date

-

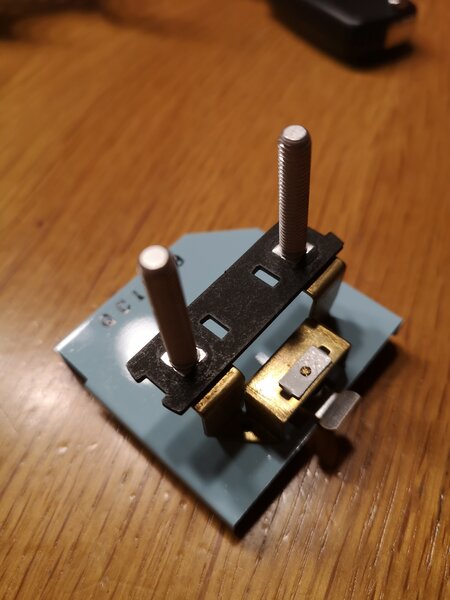

Okay I have now got some more things figured out. I have removed the instrument cluster completely to check if something actually burnt behind the cluster and to check the cluster itself. The only cable that melted is the red ammeter cable we've already talked about earlier in this thread. Everything else in the dash looks fine. I've also checked the bulkhead connector which also looks fine. What does not look fine is the ammeter. There are two bolts that hold the ammeter in place. Between the cluster and the ammeter itself is a piece of - acrylic plastic/glass I guess? It also melted away which caused the ammeter to be loose. I have no idea why they would build it like that. The cluster itself got fire marks. Due to the burnt ammeter I need a replacement I guess.

I've also made some videos to show how loose the bolts were due to the melted plastic but I can't upload them here...

I've also made some videos to show how loose the bolts were due to the melted plastic but I can't upload them here...

Yes. Insulation. It is critical the heavy power wires do not contact body metal. Shorting a battery to ground will cause a very high amperage discharge.Between the cluster and the ammeter itself is a piece of - acrylic plastic/glass I guess? It also melted away which caused the ammeter to be loose.

Chicken or egg question.

As long as the plastic doesn't get above its transition temperation everything is fine.

Two possibilities:

1. Either high current (40 amps or more) heated the plastic and the meter was no longer tight to the dash housing. This allowed the nut holding the red wire to get slightly loose. Slightly loose connection resulted in overheated crimp on the red wire's ring terminal.

OR the reverse. The red wire's ring terminal connection got overheated from high current and that heat caused the ammeters insulating block to get soft....

2. The metal to metal press fit connection between the ammeter's studs and metal plate got loose. This causes a poor connection in the meter assembly and it gets hot. The heat makes the press fit even worse....

There is always some sort of insulating material. I haven't looked at enough ammeters used other years and by other manufacturers to guess as to why this method of assembly was used.I have no idea why they would build it like that.

Yes.Due to the burnt ammeter I need a replacement I guess.

Its really important the studs are tight in the metal plate.

Some people have reinforced the stud connections.

Last edited:

Connections of all sorts are weak points.

here's an earlier model where several connections, including one of ammeter's studs got damaged.

Anyone Know What this Connector is Called?

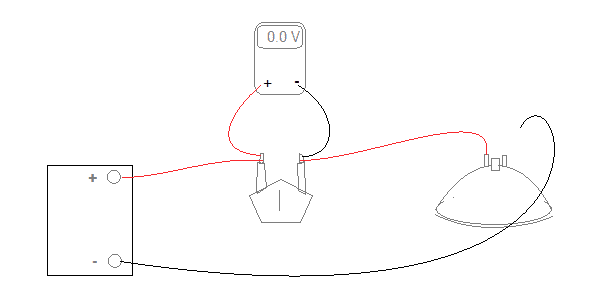

Here's a way to test an ammeter for resistance when its off the vehicle.

First just measure with a multimeter. If it shows more resistance than when the probes are touched to each other, that's a problem. Fix or replace.

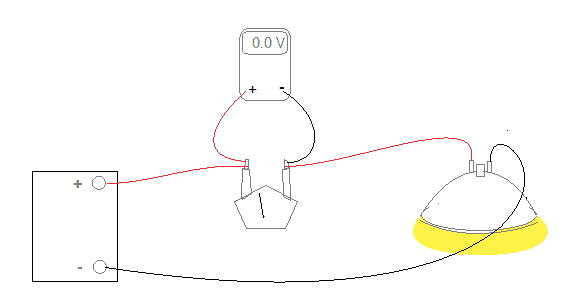

If it passes that test, then run current through it and measure for voltage drop.

Setup like this

Then complete the circuit

The ammeter will show the current, and the voltmeter will indicate the ammount of voltage drop caused by the current flowing through the meter.

It may not be zero depending on the sensitivity of the meter, but it should be pretty close to zero with only 4 to 5 amps through it.

edit:

There's some photos of a good gage in this thread, followed by some photos of damaged gages. They're not all the same as the one in your car but gives you an idea of how they should look.

here's an earlier model where several connections, including one of ammeter's studs got damaged.

Anyone Know What this Connector is Called?

Here's a way to test an ammeter for resistance when its off the vehicle.

First just measure with a multimeter. If it shows more resistance than when the probes are touched to each other, that's a problem. Fix or replace.

If it passes that test, then run current through it and measure for voltage drop.

Setup like this

Then complete the circuit

The ammeter will show the current, and the voltmeter will indicate the ammount of voltage drop caused by the current flowing through the meter.

It may not be zero depending on the sensitivity of the meter, but it should be pretty close to zero with only 4 to 5 amps through it.

edit:

There's some photos of a good gage in this thread, followed by some photos of damaged gages. They're not all the same as the one in your car but gives you an idea of how they should look.

Last edited:

I have a question now. This looks like the main problem in this whole Ammeter problem stuff is this insulating plastic part that melts away, right? So why don't make an insulator from another kind of material and rebuild the ammeter this way instead of buying a voltmeter and bypassing the ammeter?Yes. Insulation. It is critical the heavy power wires do not contact body metal. Shorting a battery to ground will cause a very high amperage discharge.

Chicken or egg question.

As long as the plastic doesn't get above its transition temperation everything is fine.

Two possibilities:

1. Either high current (40 amps or more) heated the plastic and the meter was no longer tight to the dash housing. This allowed the nut holding the red wire to get slightly loose. Slightly loose connection resulted in overheated crimp on the red wire's ring terminal.

OR the reverse. The red wire's ring terminal connection got overheated from high current and that heat caused the ammeters insulating block to get soft....

2. The metal to metal press fit connection between the ammeter's studs and metal plate got loose. This causes a poor connection in the meter assembly and it gets hot. The heat makes the press fit even worse....

There is always some sort of insulating material. I haven't looked at enough ammeters used other years and by other manufacturers to guess as to why this method of assembly was used.

Yes.

Its really important the studs are tight in the metal plate.

Some people have reinforced the stud connections.

That might help a little, but its not the cause. That piece is probably nylon or phenolic. You can look up the transistion temperature when those begine to flow (or if phenolic or bakelite) melt or burn.I have a question now. This looks like the main problem in this whole Ammeter problem stuff is this insulating plastic part that melts away, right? So why don't make an insulator from another kind of material and rebuild the ammeter this way instead of buying a voltmeter and bypassing the ammeter?

In most (all?) of the documented cases damage to the plastic is a consequence of high current going through resistance.

Paying attention to the meter will alert the driver that there is a problem developing or occuring.

1. Either high current (40 amps or more) heated the plastic and the meter was no longer tight to the dash housing. This allowed the nut holding the red wire to get slightly loose. Slightly loose connection resulted in overheated crimp on the red wire's ring terminal.

OR the reverse. The red wire's ring terminal connection got overheated from high current and that heat caused the ammeters insulating block to get soft....

2. The metal to metal press fit connection between the ammeter's studs and metal plate got loose. This causes a poor connection in the meter assembly and it gets hot. The heat makes the press fit even worse....

The weakest point in the construction of the meter's themselves is the press fit of the studs to the plate. On some years and models these seem to have had an occassional tendency to get loose over time. Maybe not enough interference in the fit or the hardness of the metal on those particular models. Some people have reinforced the press fit by soldering. I don't normally suggest this option because its not a project to learn on.

When there is too much current for the meter, there is also too much current for the rest of the circuit.

The '63 and '65 main feed connections at the bulkhead are not dependent on press fit or spring action of the terminals.

But they still will get damaged by too much current. Each time a connection gets overheated, it speeds up oxidation, so resistance increases over time unless its cleaned up and fixed.

The engine bay wire itself also showed signs of overheating.

These are the wire terminals after the owner ran the engine for something like 20-30 minutes with ammeter pegged to charge.

Last edited:

Also be aware that high charging rates can damage batteries.

Even a good battery thats getting a high charge will heat up, and that prevents it from fully charging and can permanently damage it.

A high charge on a frozen battery can be a major disaster.

Whenever possible, use a battery charger on a very low or dead battery. Battery chargers have some sort of control on the current, either automatic or manual.

www.forabodiesonly.com

www.forabodiesonly.com

Even a good battery thats getting a high charge will heat up, and that prevents it from fully charging and can permanently damage it.

A high charge on a frozen battery can be a major disaster.

Whenever possible, use a battery charger on a very low or dead battery. Battery chargers have some sort of control on the current, either automatic or manual.

Charging Battery with Alternator - Warning

We've discussed this here more than a few times. Usually about how easy it can be to cook the battery or overloading the charge wiring. Here's another reason. "Any attempt to charge a low battery by the alternator will result in stator windings burning out" ebay item # 222689173585 This is...

www.forabodiesonly.com

www.forabodiesonly.com

- Joined

- Mar 17, 2018

- Messages

- 13,383

- Reaction score

- 30,430

You rock Matt!Also be aware that high charging rates can damage batteries.

Even a good battery thats getting a high charge will heat up, and that preents it from fully charging and can permanently damage it.

A high charge on a frozen battery can be a major disaster.

Whenever possible, use a battery charger on a very low or dead battery. Battery chargers have some sort of control on the current, either automatic or manual.

[/URL]

Still interested in what you found regarding the alternator tag and the wires connections we were discusing on the previous page.It will be interesting to learn what @SlantedMark4 finds with respect to the alternator tag and other details.

Oh damn I totally forgot about that! I'm sorry, I'm gonna look for it asap.Still interested in what you found regarding the alternator tag and the wires connections we were discusing on the previous page.

Dave999

Well-Known Member

i have a rare ammeter in my car only 1300 made. and i successfully fixed it usuing fibre board, the kind used in valve amps to stop you experiencing death at 600V DC

and a range of the top hat insulators used on the ground/heat sink tab on huge power transistors

this allowed me to insulate its metal bar part from the gauge case

and allowed me to use the original mounting studs nuts and washers to mount it back in the metal gauge case with the studs insulated from the holes they pass through.

this kind of thing

https://uk.farnell.com/wurth-elektr...ING-PMAX-Medium_ROAS-Test990&gross_price=true

and this kind of thing

https://cpc.farnell.com/unbranded/3...IEkyJGIVf3ah9tY6V3xJmFvZ-XyVlrdRoCIoUQAvD_BwE

obvioulsy spend some time getting the right size i just looked for pictures to illustrate

ideally you walk into an old style electronics shop with the ammeter in hand and demonstate what you want to do and the guy/gal behind the counter should help

otherwise mail order, you end up with a pile of parts that might have worked but are "just" the wrong size....

a little bit of filing and drilling may be necessary

and a blob of locktite when needed goes a long way to provide peace of mind

use spikey washers also.

the orginal nuts on mine were brass and the spikey lock washers seem to be steel

mine is a VDO branded gauge made to chrylser specification in Australia so may be subtely different

Dave

and a range of the top hat insulators used on the ground/heat sink tab on huge power transistors

this allowed me to insulate its metal bar part from the gauge case

and allowed me to use the original mounting studs nuts and washers to mount it back in the metal gauge case with the studs insulated from the holes they pass through.

this kind of thing

https://uk.farnell.com/wurth-elektr...ING-PMAX-Medium_ROAS-Test990&gross_price=true

and this kind of thing

https://cpc.farnell.com/unbranded/3...IEkyJGIVf3ah9tY6V3xJmFvZ-XyVlrdRoCIoUQAvD_BwE

obvioulsy spend some time getting the right size i just looked for pictures to illustrate

ideally you walk into an old style electronics shop with the ammeter in hand and demonstate what you want to do and the guy/gal behind the counter should help

otherwise mail order, you end up with a pile of parts that might have worked but are "just" the wrong size....

a little bit of filing and drilling may be necessary

and a blob of locktite when needed goes a long way to provide peace of mind

use spikey washers also.

the orginal nuts on mine were brass and the spikey lock washers seem to be steel

mine is a VDO branded gauge made to chrylser specification in Australia so may be subtely different

Dave

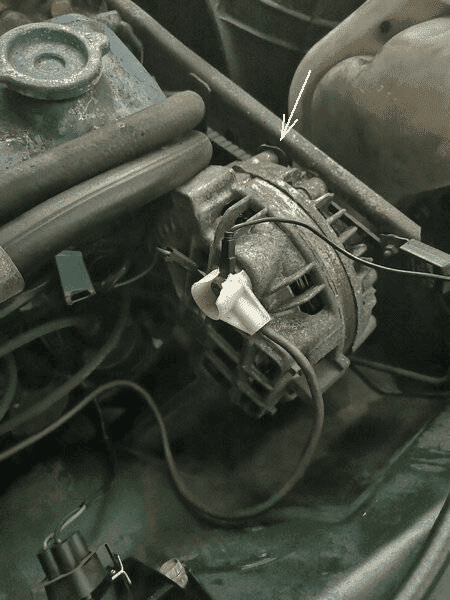

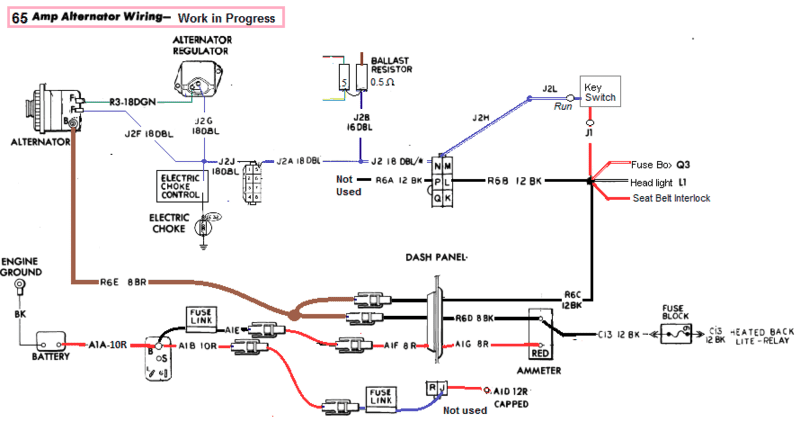

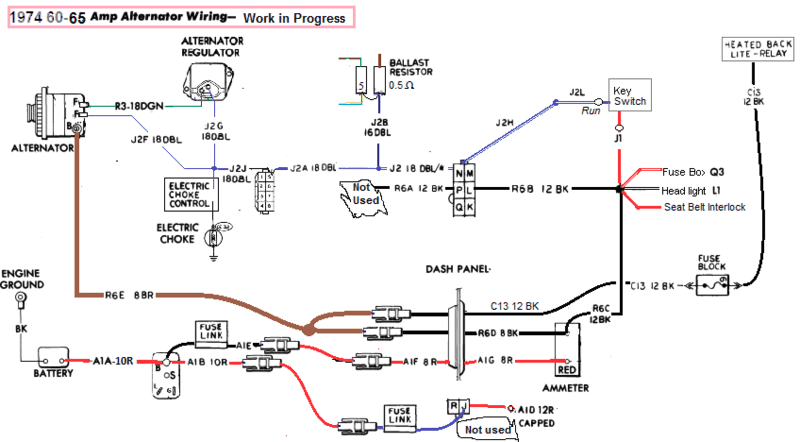

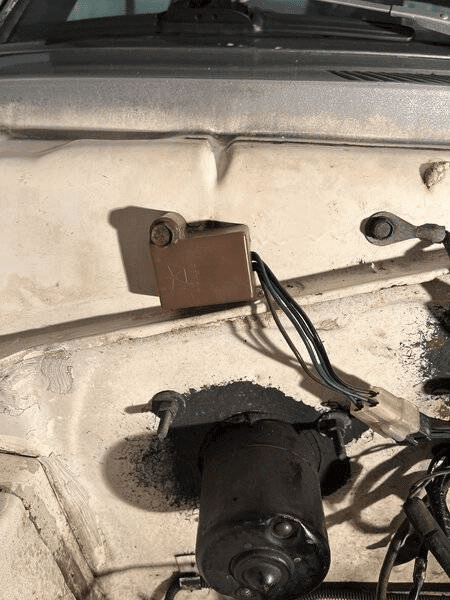

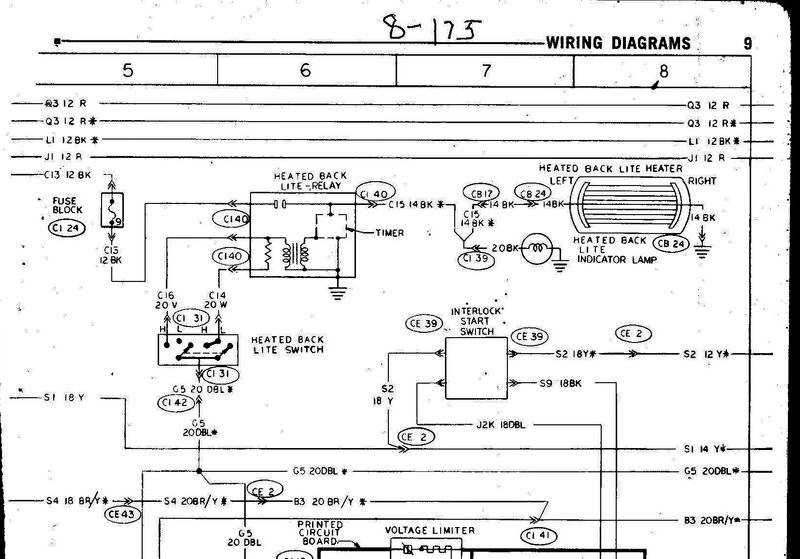

The questions are about this 1974 Heavy Duty Alternator option with Rear Window defroster.

The wiring is different than we've seen, and there also is some question as to which alternator this car got as there is some confusion in the manuals and sales info.

see this post

it looks to be a Chrysler (as opposed to a Leece Neville).

A tag on it was originally colored and stamped with a rating or similar identifier.

The other question was about the main wire connections:

We plainly see there are wires, at least 12 gage, going through the grommet.

It also appears that some of the standard wires were left connected. Did they operate in parallel? Or was a segment removed or cut and capped?

Those would all be good to know, especially if one needed to do dome trouble shooting, or in Mark's situation, if he wants to replace wires using bits from another harness.

See this post

Best guesses is

the standard battery feed was removed or capped inside.

one branch of the alternator output goes direct to the main splice

OR one branch of the alternator output goes direct to the heated back lite relay.

One thing that bothers me as that we haven't identified fusible links protecting the 12 gage wires.

There should be one or two blue fusible links (16 gage) to protect those wires.

If the black fusible link is really black, then its 12 gage and only protecting the 8 gage wires.

The wiring is different than we've seen, and there also is some question as to which alternator this car got as there is some confusion in the manuals and sales info.

see this post

it looks to be a Chrysler (as opposed to a Leece Neville).

A tag on it was originally colored and stamped with a rating or similar identifier.

The other question was about the main wire connections:

We plainly see there are wires, at least 12 gage, going through the grommet.

It also appears that some of the standard wires were left connected. Did they operate in parallel? Or was a segment removed or cut and capped?

Those would all be good to know, especially if one needed to do dome trouble shooting, or in Mark's situation, if he wants to replace wires using bits from another harness.

See this post

Best guesses is

the standard battery feed was removed or capped inside.

one branch of the alternator output goes direct to the main splice

OR one branch of the alternator output goes direct to the heated back lite relay.

One thing that bothers me as that we haven't identified fusible links protecting the 12 gage wires.

There should be one or two blue fusible links (16 gage) to protect those wires.

If the black fusible link is really black, then its 12 gage and only protecting the 8 gage wires.

Okay my friend, I have done some research but my results are not what I was expecting... I'm actually a bit disappointed.Still interested in what you found regarding the alternator tag and the wires connections we were discusing on the previous page.

As a reminder: We are looking at a '74 built car which was exported/imported to Switzerland, so I'm not sure about some modifications done by the Swiss...

First of all, yes, there's a tag on the alternator. I'm assuming I can take it off to read it properly? It seems to be bolted on with a screw but I don't want to unscrew something important (I've never worked on an alternator).

Now the confusion starts: There's a split on the positive battery cable which isn't showed on the chart. The A1A-10R is correct, but there's a bigger one going on the starter, but that must be standard, obviously. I'm just confused why this isn't on the chart.

I'm not really sure what specific wires you mean. Only thing I know to be different from a "normal" harness is the ammeter wires, which is split in two wires (alternator wire, R6E 8BR), continuing as R6D 8BK / C13 12BK). Those two black wires lead to the ammeter, together with AIF 8R.It also appears that some of the standard wires were left connected. Did they operate in parallel? Or was a segment removed or cut and capped?

You've been asking if C13 12BK is going direct to the heated back lite relay. To be honest, I have no idea because I don't know where the heated back lite relay actually is. It must be under the dash? The other problem is the wiring itself, I'd have to remove the cluster (again) to see where the wires go, unless I've completely misunderstood. Most wires are tied up in insulation tape aswell so finding out where it leads makes it difficult unless I unwrap everything. There's a huge mess under the dash because the pre-owner was a d***head...

My other problem is, we have had so many posts in this thread, I've lost focus on what details we were looking for, except for the alternator questions. I'd like to get together all your questions to one post (if possible), so it's also easier to find the answers if anybody else needs those informations.

What else I can offer is to look at every wire in my harness and create a new chart, but that'd take a huge amount of time. The reason I talk about that is simple: I've checked the charts you've sent and found out some things are missing or not the same as the wires in my car (or they just don't seem to be the same). I mean it starts at the starter relay. There are only two wires in the chart, but I count like 6 or so on my car.

I'm going to re-read the previous posts tomorrow morning again (I've been up for like 19h now) to see if I've misread something.

I actually want to excuse me to take so much time with all this stuff here. It's not my intention to make this thread this ... troublesome? (Google translater said that's a word)

Ah yes, I wanna tell someting about the ammeter itself to bring at leat this topic to an end.

As you know, my ammeter melted on the backside, probably because of the stuts that got loose over the years. This probably caused a bad connection, and then to overheating.

I've ordered a replacement part, OER 3592196, but it wasn't cheap (130$). It has a different insulation on the backside. I've driven like 400km since without any problem, so this might be a solution instead of getting a voltmeter and an alternator bypass. I'm sure I'm not the first to do this, but I've just wanted to show what I've done.

As you know, my ammeter melted on the backside, probably because of the stuts that got loose over the years. This probably caused a bad connection, and then to overheating.

I've ordered a replacement part, OER 3592196, but it wasn't cheap (130$). It has a different insulation on the backside. I've driven like 400km since without any problem, so this might be a solution instead of getting a voltmeter and an alternator bypass. I'm sure I'm not the first to do this, but I've just wanted to show what I've done.

Mark,Now the confusion starts: There's a split on the positive battery cable which isn't showed on the chart. The A1A-10R is correct, but there's a bigger one going on the starter, but that must be standard, obviously. I'm just confused why this isn't on the chart.

My drawing is a simplification focusing only on the main circuits for powering the car.

The service manual drawings show all of the wires. Do you have a copy?

Like this ?

it shows the battery connectors as CE27

The positive has as a 6 ga wire to the starter and the 10 ga wire to the starter relay.

First of all, yes, there's a tag on the alternator. I'm assuming I can take it off to read it properly? It seems to be bolted on with a screw but I don't want to unscrew something important (I've never worked on an alternator).

Best leave that screw alone. It is one of three screws holding the alternator together.

When you change the v-belt, as you rotate the alternator, maybe the front of the tag will be readable.

I don't know the meaning of the numbers on the back.

It looks black.

Page 8-138 in the 1974 service manual says natural is '60 amp' and black is '65 amp'

Glad you brought the subject back. Because of your question, just went out and removed the screw your referring to from two alternators. Had no problem replacing them. It takes a 5/16 six point socket or wrench. Of course you can remove the alternator if you don't mind the additional time. To get good photos of the wiring harness, you will have to remove the cluster. Sounds like you have plenty of experience with that. It really depends on how far you want to go to answer our questions. Please don't unwrap the wiring harness just to answer a few questions.

From the 1974 factory service manual:

From under the instrument panel to the right side of radio support bracket, remove screw attaching relay and bracket assembly to lower reinforcement.

Disconnect electrical leads from relay.

Remove relay.

Maybe this will help you find the relay. Many pictures of relay on eBay. Search for: # 3746691

From under the instrument panel to the right side of radio support bracket, remove screw attaching relay and bracket assembly to lower reinforcement.

Disconnect electrical leads from relay.

Remove relay.

Maybe this will help you find the relay. Many pictures of relay on eBay. Search for: # 3746691

Exactly. Thats what I meant in the question about standard versus optional.I mean it starts at the starter relay. There are only two wires in the chart, but I count like 6 or so on my car.

Chrysler had a standard harness.I'm not really sure what specific wires you mean. Only thing I know to be different from a "normal" harness is the ammeter wires, which is split in two wires (alternator wire, R6E 8BR), continuing as R6D 8BK / C13 12BK). Those two black wires lead to the ammeter, together with AIF 8R.

When the optional alternator or heated back light was installed, another set of wires was added and the standard wires cut, removed or left in place. We don't know what the factory workers actually did.

Standard battery circuit connection at the starter relay is just sires A1A and A1B

For your car, A1E and A1F were added.

A1B was left in place even though it wasn't going to be used.

Now lets see if we can explain the other wires on the starter relay.

When the key is all the way in the start position, power is available in wire S1.

Inside the relay, this connects with wire S4. If the safety switch on the transmission is closed, the circuit will be complete.

Current flows through the key switch and activates the starter relay.

When the relay is activated, the battery junction gets connected to the terminal below it with wire S5.

Wire S5 goes to the solenoid connection on the starter. The solenoid activates and connects the heavy cable on the starter to the starter windings. Starter is now powered.

This leaves "Brown 2" wire.

Last edited:

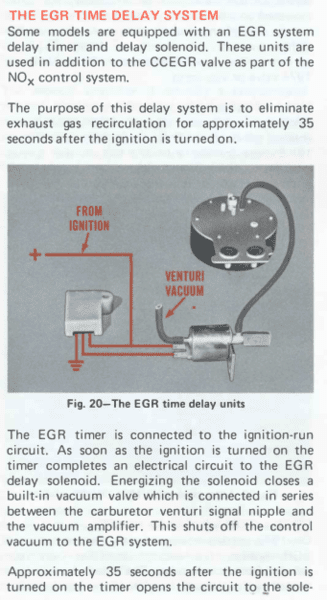

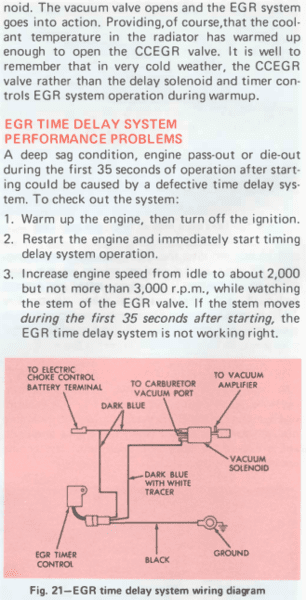

@cudamark says this is the EGR timer.

www.forabodiesonly.com

www.forabodiesonly.com

mymopar.com

mymopar.com

Explanation doesn't match perfectly but basically concept seems to match what you have on this car.

Need help identifying

Trying to figure what these are in the wiring on the firewall and inner fender. I’m trying to clean up the engine bay for paint and would like to remove these if possible. Im almost positive the 2nd picture is the seatbelt interlock. Two of the wires were already looped together to disable it...

www.forabodiesonly.com

www.forabodiesonly.com

Browse MTSC by Model Year – 1974 – MyMopar

mymopar.com

mymopar.com

Explanation doesn't match perfectly but basically concept seems to match what you have on this car.

Last edited:

Thank you very much for the part number! It actually helped me identifying the part.From the 1974 factory service manual:

From under the instrument panel to the right side of radio support bracket, remove screw attaching relay and bracket assembly to lower reinforcement.

Disconnect electrical leads from relay.

Remove relay.

Maybe this will help you find the relay. Many pictures of relay on eBay. Search for: # 3746691

It is like that. I've found the right relay, thanks to @townsendOR one branch of the alternator output goes direct to the heated back lite relay.

The wires are wrapped and leading straight to the ammeter (or C13 12BK at least). What confuses me is, there's a fuse block on the chart, but I haven't found one...? It looks like there's nothing in between...

One thing that bothers me as that we haven't identified fusible links protecting the 12 gage wires.

There should be one or two blue fusible links (16 gage) to protect those wires.

If the black fusible link is really black, then its 12 gage and only protecting the 8 gage wires.

You've asked me this earlier, but I didn't understand what wires you mean. I'm assuming you're interested in the ammeter wires R6D / C13. There are not fuse links at all. The only wires with a fusible link I've found were the ones that are already on the chart. Or let's say, what I have found...

How I see, a fusible link is in the standard wiring, on A1B, with another fusible link on the added wire, A1E.

Yes It is. I've checked it again and yes, it's black, but I can't read the stamped numbers.It looks black.

Sounds like your making some progress, so let's move forward. The fuse or circuit breaker is located under the dash on the far left near the fuse box. It's a small black box with 2 black wires connected to it. The size of the box is about 1 1/2 by 1/2 by 1/2 in inches. Part #3764198.

Here's a picture.

By the way that part number also fits Abodies along with C and B bodies.

By the way that part number also fits Abodies along with C and B bodies.

Here's a picture.

Mopar NOS 75-77 Ply Dodge Chry B C Body 30AMP TrailerTow Circuit Breaker 3764198 | eBay

This item is in good condition. adjust your invoice.

www.ebay.com

Bugman

Well-Known Member

Fuse 9 for heated rear window, amp rating not given

-